Multiple dust ports, Two machines on same branch line, Calculating duct resistance – Woodstock SHOP FOX W1816 User Manual

Page 33

-31-

W1816 Owner's Manual (Mfg. Since 10/09)

O

PE

R

ATIO

NS

Multiple Dust Ports

If your machine has multiple dust ports, add the total CFM

given for each dust port size from

Figure 40. Refer to

the chart in

Figure 45 and find the CFM that is closest to

your total to determine the correct branch size. Split the

branch line just before the dust ports with matching duct

sizes.

Two Machines on Same Branch Line

If both machines will be running at the same time,

add the total CFM given for each dust port size from

Figure 40.

If both the machines will never be run at the same time,

reference the machine with biggest dust port to

Figure

45 and add blast gates after the Y-branch to open/close

the line to each machine.

Calculating Duct Resistance

Adding duct work, elbows, branches and any other

components to a duct line increases airflow resistance

(static pressure loss). This resistance can be minimized by

using rigid (smooth) pipe and gradual curves, as opposed

to flexible pipe and 90˚ elbows.

To help you think about this resistance, imagine riding a

bicycle in a tunnel that is an exact replica of your duct

work. If the inside of the tunnel is very bumpy (flexible

pipe) and has a lot of sharp turns (90˚ elbows), it will take

a lot more effort to travel from one end to the other.

The purpose of calculating the resistance is to determine

if it is low enough from the machine to the dust collector

to meet the given CFM requirement for the machine. Use

the charts in

Figure 46 to calculate the resistance of duct

work.

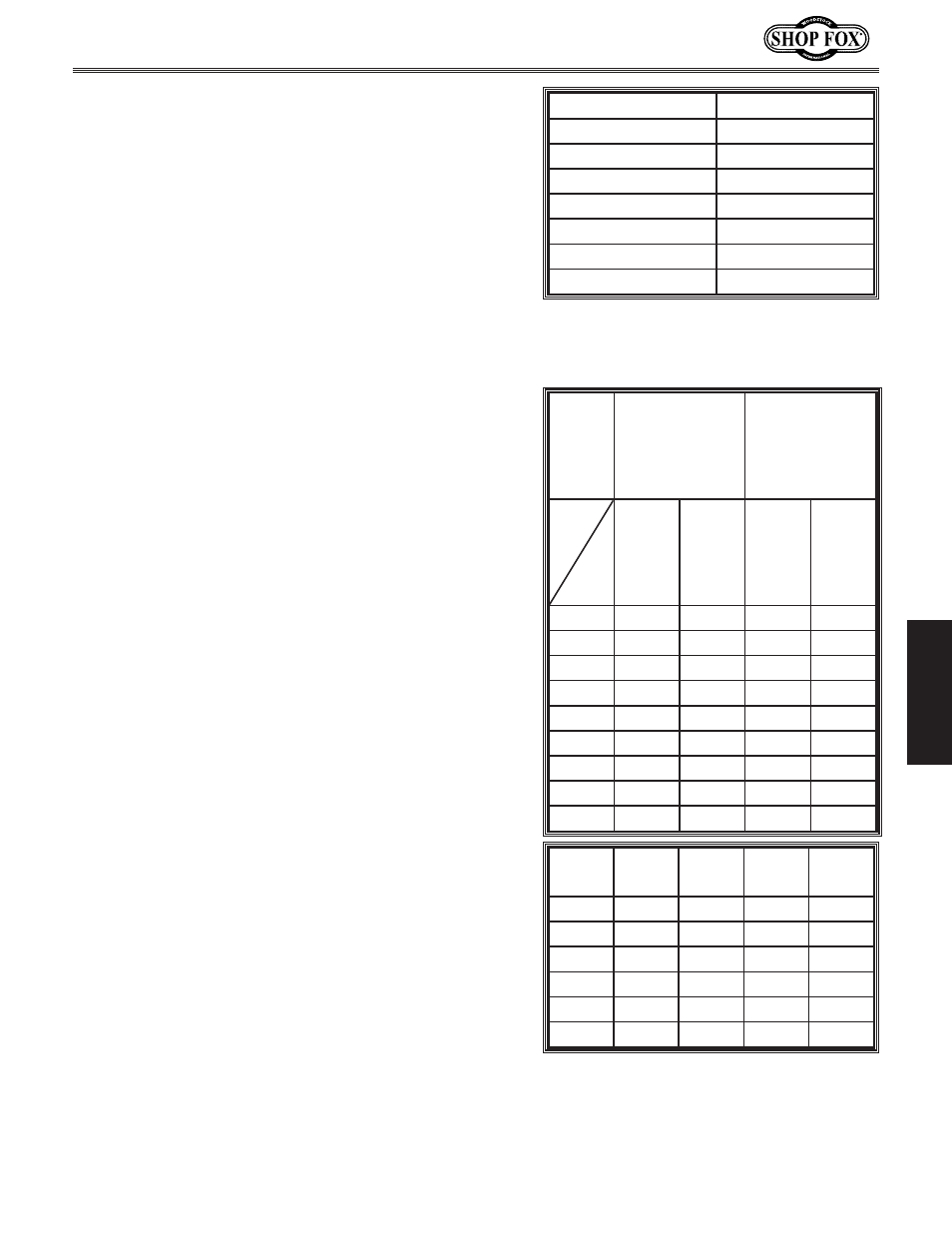

Total CFM

Branch Line Size

600

5"

700

5"

800

6"

1000

6"

1200

7"

1400

8"

1600

8"

Figure 45. Branch line sizing chart by

total CFM (for use when multiple machines

share the line).

Duct

Dia.

Approximate

Static

Pressure Loss

Per Foot of

Rigid Pipe

Approximate

Static

Pressure Loss

Per Foot of

Flex Pipe

Main

Lines

@

3500

FPM

Branch

Lines

@

4000

FPM

Main

Lines

@

3500

FPM

Branch

Lines

@

4000

FPM

2"

.091

.122

.35

.453

2.5"

.08

.107

.306

.397

3"

.071

.094

.271

.352

4"

.057

.075

.215

.28

5"

.046

.059

.172

.225

6"

.037

.047

.136

.18

7"

.029

.036

.106

.141

8"

.023

.027

.08

.108

9"

.017

.019

.057

.079

Fitting

Dia.

90˚

Elbow

45˚

Elbow

45˚

Y

90

Y

3"

.47

.235

.282

.188

4"

.45

.225

.375

.225

5"

.531

.266

.354

.236

6"

.564

.282

.329

.235

7"

.468

.234

.324

.216

8"

.405

.203

.297

.189

Figure 46. Airflow resistance (static

pressure loss) charts.