Service – Graco Inc. 218-745 User Manual

Page 21

21

307-712

SERVICE

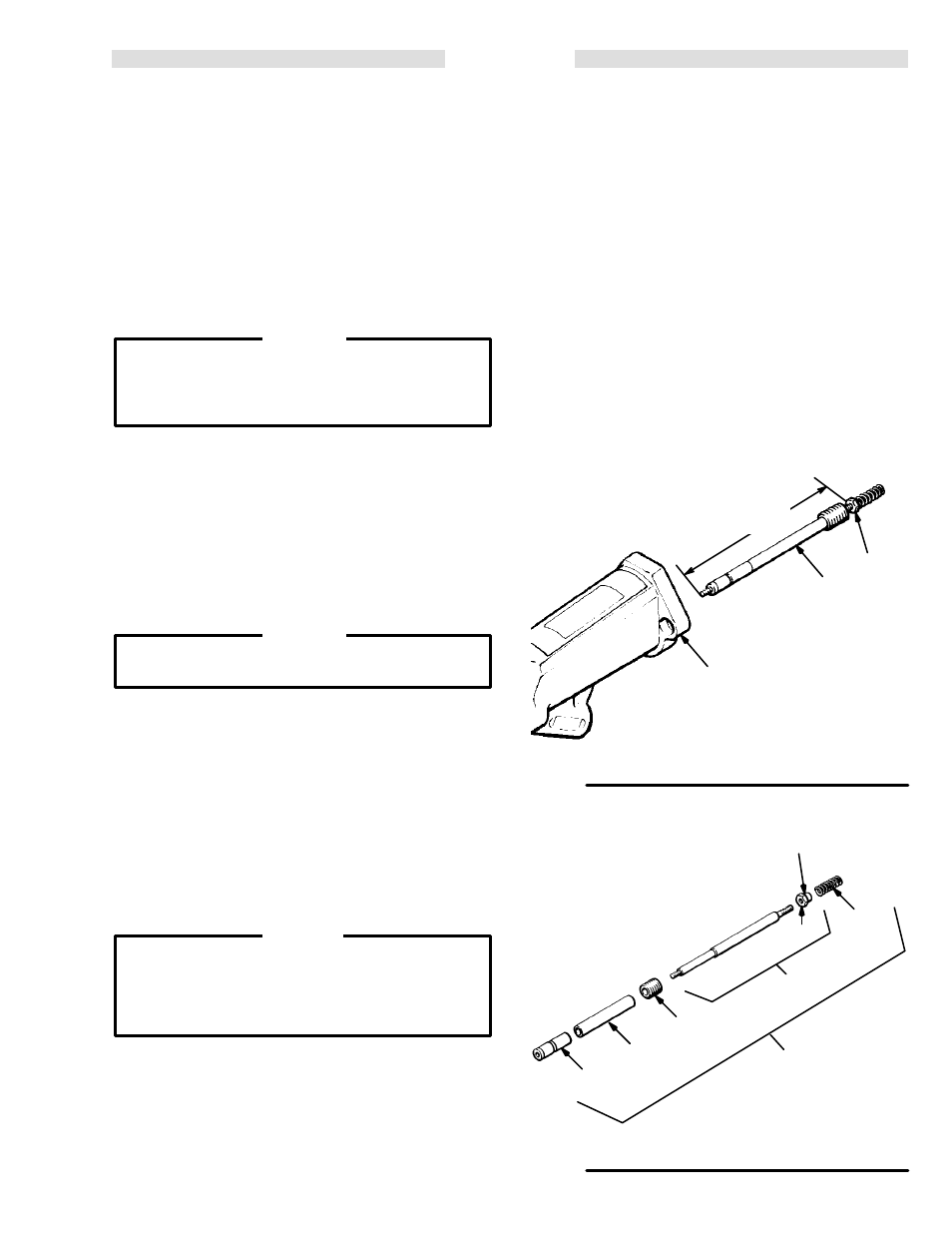

5. Carefully remove the fluid needle assembly (9) from

the rear part of the gun barrel (20). See Fig 15. If the

packing assembly (9a) or insulator (9g) are still in

the barrel, insert the packing removal rod (66d) into

the front of the barrel to gently push them out. Refer

to Fig 16.

NOTE: If the insulator (9g) is removed, be sure to install

it so the insulator end with holes is facing the

packing assembly (9a).

6. Wipe the internal surfaces of the barrel clean with a

soft brush or cloth.

CAUTION

Clean all parts in nonĆconductive solvent compatĆ

ible with the fluid being used, such as xylol or minĆ

eral spirits. Use of conductive solvents can cause

the gun to malfunction.

7. Remove the packing assembly (9a) from the needle

(9b).

NOTE: If the position of the adjusting nut (9c) is

changed, install the adjusting nut to the apĆ

proximate dimension shown in Fig 15. (Final adĆ

justment will be made in step 15.) If the spring

(9f) was removed, reinstall it over the nut (9d).

8. Install the new packing assembly (9a).

CAUTION

Carefully screw needle (9b) into new packing

assembly (9a) to avoid damaging the seals.

9. Test the drag on the fluid needle. It should be apĆ

proximately 2.5 to 3 lbs (use a small spring scale to

measure). If the adjustment is out of tolerance,

tighten or loosen the adjusting screw on the packĆ

ing assembly (9a) slightly and retest. Continue to

adjust until the tolerance is correct.

10. Install the entire fluid needle assembly (9) into the

gun barrel, from the back of the barrel.

11. Firmly tighten the packing nut (9e) down until it botĆ

toms.

CAUTION

When checking the fluid needle movement, DO

NOT move the needle out of the gun barrel more

than 6.35 mm (1/4 in.) to avoid pulling the needle

out of the packing area and damaging the packĆ

ings.

12. Install the barrel as described under Barrel

Removal.

13. Install the electrode as described under Electrode

Replacement.

14. Install the air cap assembly and fluid nozzle as

described in To Clean or Change Air Cap and

Fluid Nozzle.

15. Trigger the gun to check the needle adjustment.

The air should come fully on before the fluid comes

on. Adjust the needle adjusting nut (9c) until the

proper lead and lag is achieved.

If the fluid comes on too soon, remove the trigger

and back the needle adjusting nut (9c) out (away

from the barrel) slightly.

If the fluid comes on too late, tighten the needle

adjusting nut (9c) slightly (turn towards barrel).

After adjustment is complete, tighten the locking nut

(9d) against the adjusting nut (9c).

Fig 15

20

9

KEY

9

Fluid Needle Assembly

9c

Needle Adjusting Nut

20

Gun Barrel

132.7 mm

(5.2 in.)

9

9a

9b

9c

9e

9f

9g

Fig 16

KEY

9

Fluid Needle Assembly

9a

Needle Packing Assembly

9b

Fluid Needle

9c

Adjusting Nut

9d

Locking Nut

9e

Packing Nut

9f

Spring

9g

Insulator

9c

9d