Gun operation troubleshooting chart – Graco Inc. 218-745 User Manual

Page 14

14

307-712

GUN OPERATION TROUBLESHOOTING CHART

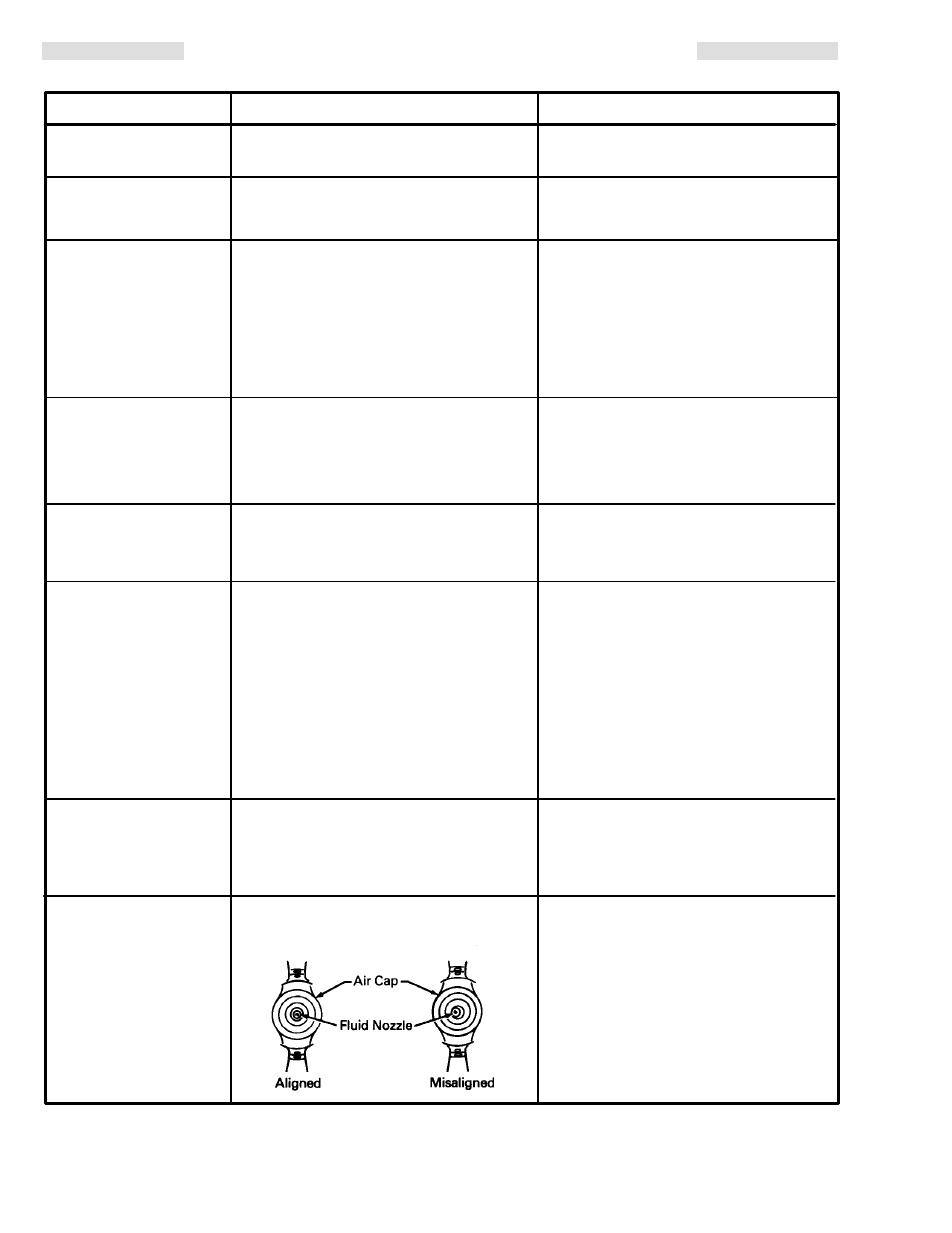

Misalignment between air cap and

Remove and clean air cap and fluid

fluid nozzle.

nozzle as described on page 12, then

reinstall them.

PROBLEM

CAUSE

SOLUTION

Worn needle packing.

Replace packing assembly.

See page 20.

Air leakage from front

of gun.

Fluid leakage from

front of gun.

Air valve not seating properly.

Clean, service. See page 24.

Air stem packing too tight.

Loosen packing. See page 24.

Too much air pressure.

Reduce, use least air pressure

needed for good results.

Fluid thinned too much.

Properly thin fluid.

Excessive spray fog.

Electrode worn or damaged.

Replace electrode. See page 18.

Worn fluid seat.

Replace fluid nozzle and/or electrode.

See page 18.

Fluid packing too tight.

Adjust packing screw. See page 20.

Loose fluid nozzle.

Tighten fluid nozzle. See page 12.

Cylinder air to gun not completely shut off.

Adjust screw.

Leakage from fluid pack-

ing nut.

Insufficient air pressure.

Increase, use least air pressure

needed for good results.

Fluid poorly mixed or filtered.

Remix or refilter fluid.

Improper thinner being used.

Use proper thinner.

“Orange Peel” finish.

No fluid sprays from

gun.

Fluid low.

Check, add if necessary.

Damaged air cap.

Replace air cap. See page 12.

Dirty or clogged fluid nozzle.

Clean fluid nozzle. See page 12.

Damaged fluid nozzle.

Check, replace fluid nozzle.

See page 12.

Air Valve not actuating.

Check cylinder air, fluid needle packing,

and needle. Replace parts as necessary.

See page 21.

Damaged fluid needle

Replace. See page 20.

Exhaust air flow insufficient or not directed Check for proper CFM, check baffles

properly.

and direction of air flow.

Improper distance between gun and

Adjust distance to 203–305 mm

work piece.

(8–12 in.).

Equipment covered

with fluid.

Dirty air cap.