Grizzly 1 1/2 HP Cyclone G0703 User Manual

Page 32

-30-

Model g0703/g0703p (Mfg. Since 3/12)

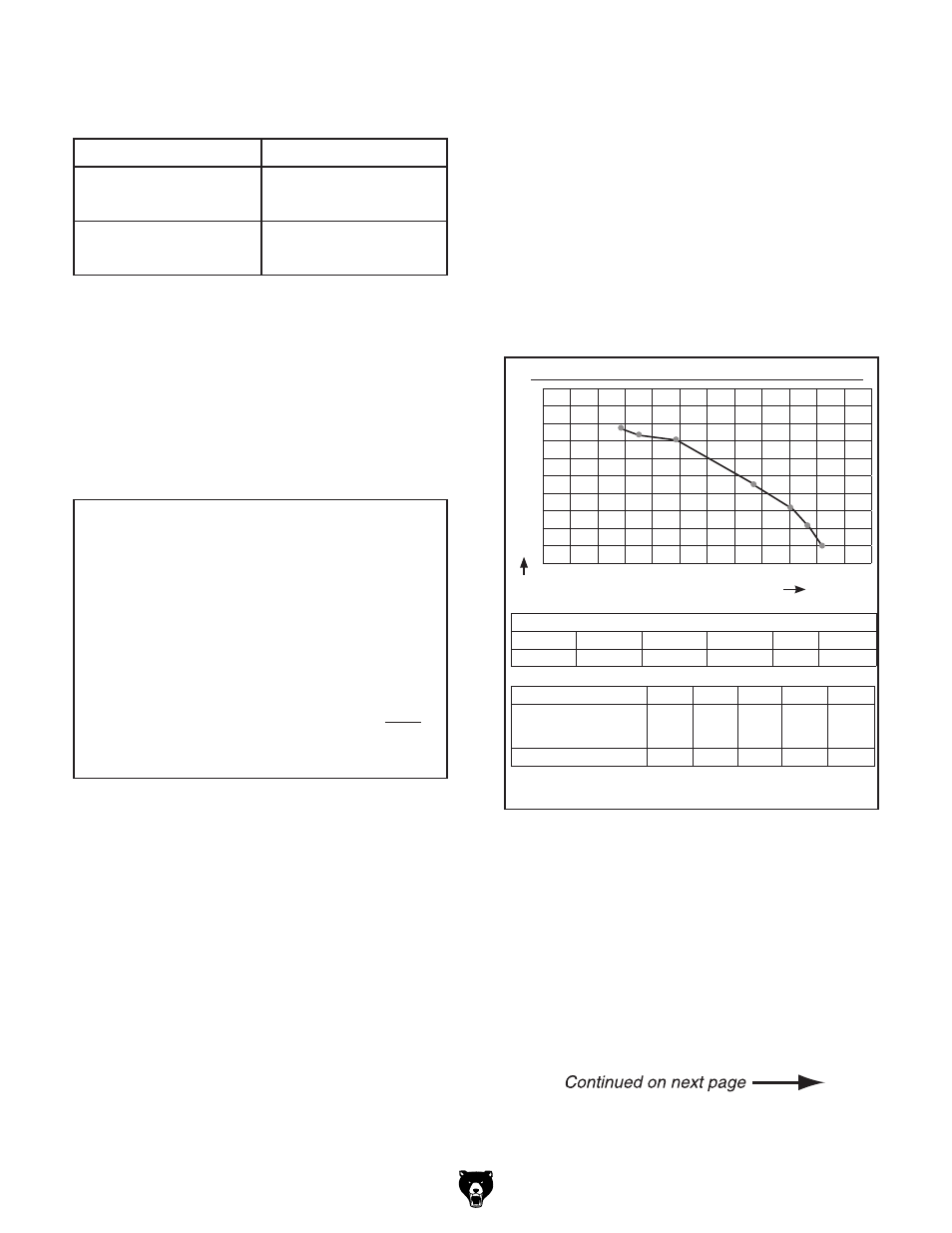

figure 45. Additional factors affecting static

pressure.

figure 46. totaling static pressure numbers.

Main Line

6" Rigid Pipe (0.037) at 20'

................ 0.740

Branch Line

4" Rigid Pipe (0.075) at 10'

................ 0.750

4" Flex Pipe (0.28) at 5' ........................ 1.400

Elbows/Branches

6" 45˚ Y-Branch

................................ 0.329

4" 45˚ Elbow ........................................ 0.225

Additional Factors

Seasoned Filter

................................ 1.000

Total Static Pressure Loss ................ 4.444

additional factors

static pressure

Seasoned (well used)

dust Collection Filter

1"

Entry loss at large

Machine hood

2"

4. total your list as shown in the example below

to come up with your overall static pressure

loss number for that line.

note: Always account for a seasoned filter,

so you don't end up with a system that only

works right when the filter is clean.

note: When calculating static pressure loss

to determine if multiple lines can be left open

at the same time, only include the main line

numbers once.

3. Add the additional factors from the following-

table to your list.

5. Compare the total static pressure loss for that

line to the closest CFM given in

figure 47.

example: the g0703/g0703p performance

curve is illustrated in figure 47. Find 4.8 on

the Static pressure axis (the amount of total

static pressure loss calculated in

figure 28),

then refer to the closest value on the CFM

axis—approximately 708 CFM.

the 708 CFM for the static pressure loss of

the line connected to the router is well above

the 220 CFM requirement of that machine.

— if the CFM for static pressure loss is

above the requirement of the machine

connected to the end of that branch line,

then dust collection will most likely be

successful. Congratulations! you've just

designed your own dust system. refer to

the

accessories section on page 37 to

start buying the components necessary to

make your system a reality.

the airflow test probe is located 1.5x duct diameter upstream from

the air inlet. test pipe length is a minimum of 10x duct diameter.

g0703/g0703p performance curve

1000

900

800

700

600

500

400

300

200

100

0

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0 11.0

cfm

static pressure (inch/h2o)

1.5 hp dust collector performance results

max cfm max sp

hp

volts

inlet

impeller

775

10

1-1/2 hp

110/220V 6"

13

1

⁄

2

"

restrictor plate (inch)

dia. 6" dia. 5" dia. 4" dia. 3" dia. 2"

Static pressure (inch/

h2o)

1.8

3.4

4.8

7.6

9.6

CFM

775

742

708

448

316

figure 47. g0703/g0703p performance curve

table and data.

performance curve