Guardian Technologies 5209 User Manual

Page 61

section 6

Diagnostic tests

Page 59

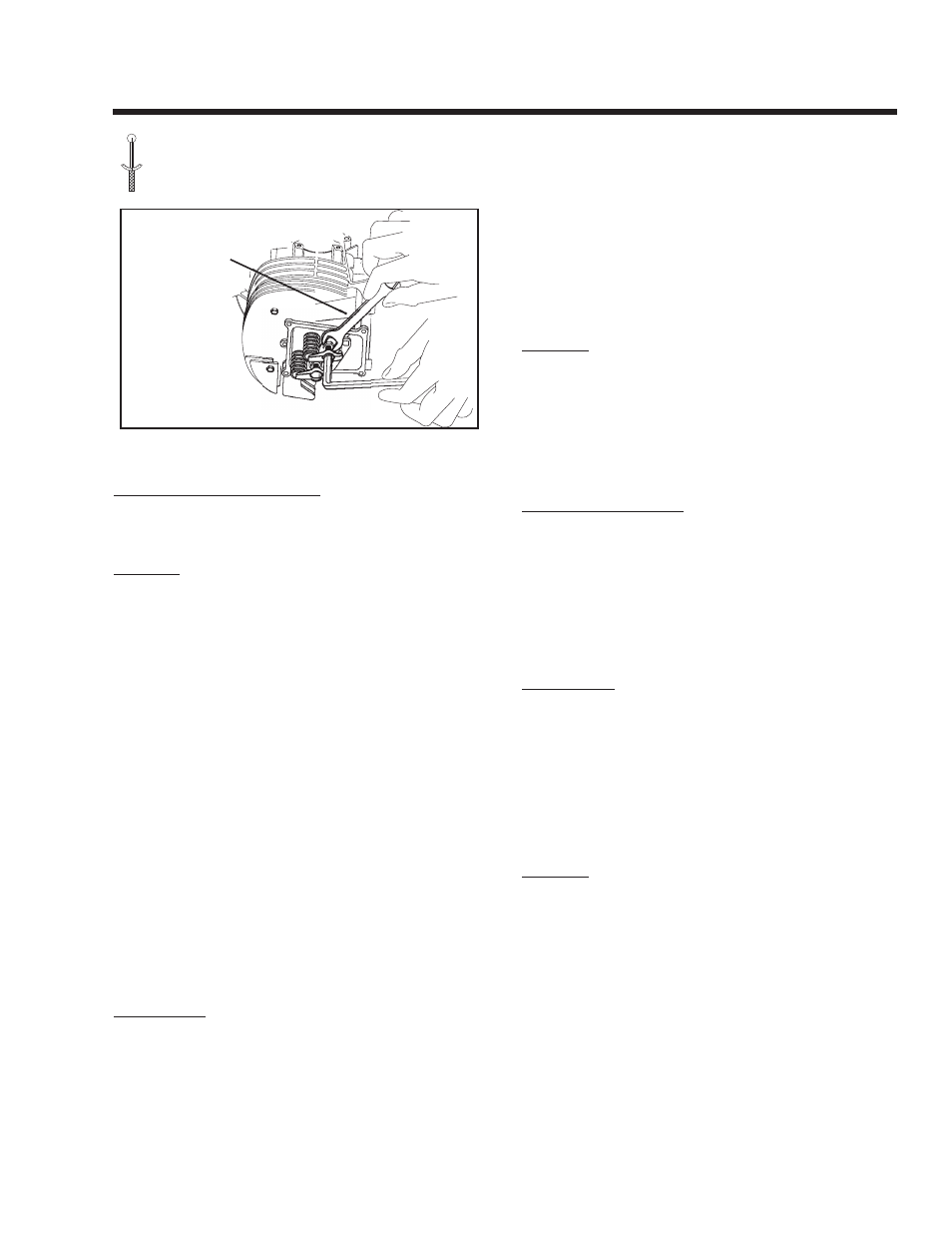

toRQue speciFication

RocKeR aRM JaM nut

168 inch-pounds (19 nm)

CROW'S FOOT

Figure 6-52 – Tightening the Jam Nut

INSTALL ROCKER ARM COVER

1. Use a new rocker arm cover gasket. Install the rocker arm

cover and retain with four screws.

RESULTS:

Adjust valves to specification and retest. If problem

continues, refer to Flow Chart.

TEST 41 - CHECk ENgINE / CYLINdER LEAk

dOWN TEST / COMPRESSION TEST

Most engine problems may be classified as one or a

combination of the following:

• Will not start.

• Starts hard.

• Lack of power.

• Runs rough.

• Vibration.

• Overheating.

• High oil consumption.

The Cylinder Leak Down Tester (Generac P/N

0F77000SRV) checks the sealing (compression) abil-

ity of the engine by measuring air leakage from the

combustion chamber. Compression loss can present

many different symptoms. This test is designed to

detect the section of the engine where the fault lies

before disassembling the engine.

PROCEDURE:

1. Remove a spark plug.

2. Gain access to the flywheel. Remove the valve cover.

3. Rotate the engine crankshaft until the piston reaches top dead

center (TDC). Both valves should be closed.

4. Lock the flywheel at top dead center.

5. Attach cylinder leak down tester adapter to spark plug hole.

6. Connect an air source of at least 90 psi to the leak down tester.

7. Adjust the regulated pressure on the gauge to 80 psi.

8. Read the right hand gauge on the tester for cylinder pressure. 20

percent leakage is normally acceptable. Use good judgement,

and listen for air escaping at the carburetor, the exhaust, and the

crankcase breather. This will determine where the fault lies.

9. Repeat Steps 1 through 8 on remaining cylinder.

RESULTS:

• Air escapes at the carburetor – check intake valve.

• Air escapes through the exhaust – check exhaust

valve.

• Air escapes through the breather – check piston

rings.

• Air escapes from the cylinder head – the head gas-

ket should be replaced.

CHECK COMPRESSION:

Lost or reduced engine compression can result in (a)

failure of the engine to start, or (b) rough operation.

One or more of the following will usually cause loss of

compression:

• Blown or leaking cylinder head gasket.

• Improperly seated or sticking-valves.

• Worn Piston rings or cylinder. (This will also result in

high oil consumption).

PROCEDURE:

1. Remove both spark plugs.

2. Insert a compression gauge into either cylinder.

3. Crank the engine until there is no further increase in pressure.

4. Record the highest reading obtained.

5. Repeat the procedure for the remaining cylinder and record the

highest reading.

RESULTS:

Normal compression is approximately 150 psi. The dif-

ference in pressure between the two cylinders should

not exceed 25 percent. If the difference is greater than

25 percent, loss of compression in the lowest reading

cylinder is indicated.

Example 1: If the pressure reading of cylinder #1 is

165 psi and of cylinder #2, 160 psi, the difference is 5

psi. Divide "5" by the highest reading (165) to obtain

the percentage of 3.0 percent.

Example 2: No. 1 cylinder reads 160 psi; No. 2 cylinder

reads 100 psi. The difference is 60 psi. Divide "60" by

"160" to obtain "37.5" percent. Loss of compression in

No. 2 cylinder is indicated.

If compression is poor, look for one or more of the fol-

lowing causes: