Guardian Technologies 5209 User Manual

Page 59

section 6

Diagnostic tests

Page 57

9. Now check the flywheel magnet by holding a screwdriver at the

extreme end of its handle and with its point down. When the tip

of the screwdriver is moved to within 3/4 inch (19mm) of the

magnet, the blade should be pulled in against the magnet.

10. Now check the flywheel key. The flywheel’s taper is locked on

the crankshaft taper by the torque of the flywheel nut. A keyway

is provided for alignment only and theoretically carries no load.

Note: If the flywheel key becomes sheared or even

partially sheared, ignition timing can change.

Incorrect timing can result in hard starting or fail-

ure to start.

RESULTS:

If sparking still does not occur after adjusting the

armature air gap, testing the ground wires and per-

forming the basic flywheel test, replace the ignition

magneto(s).

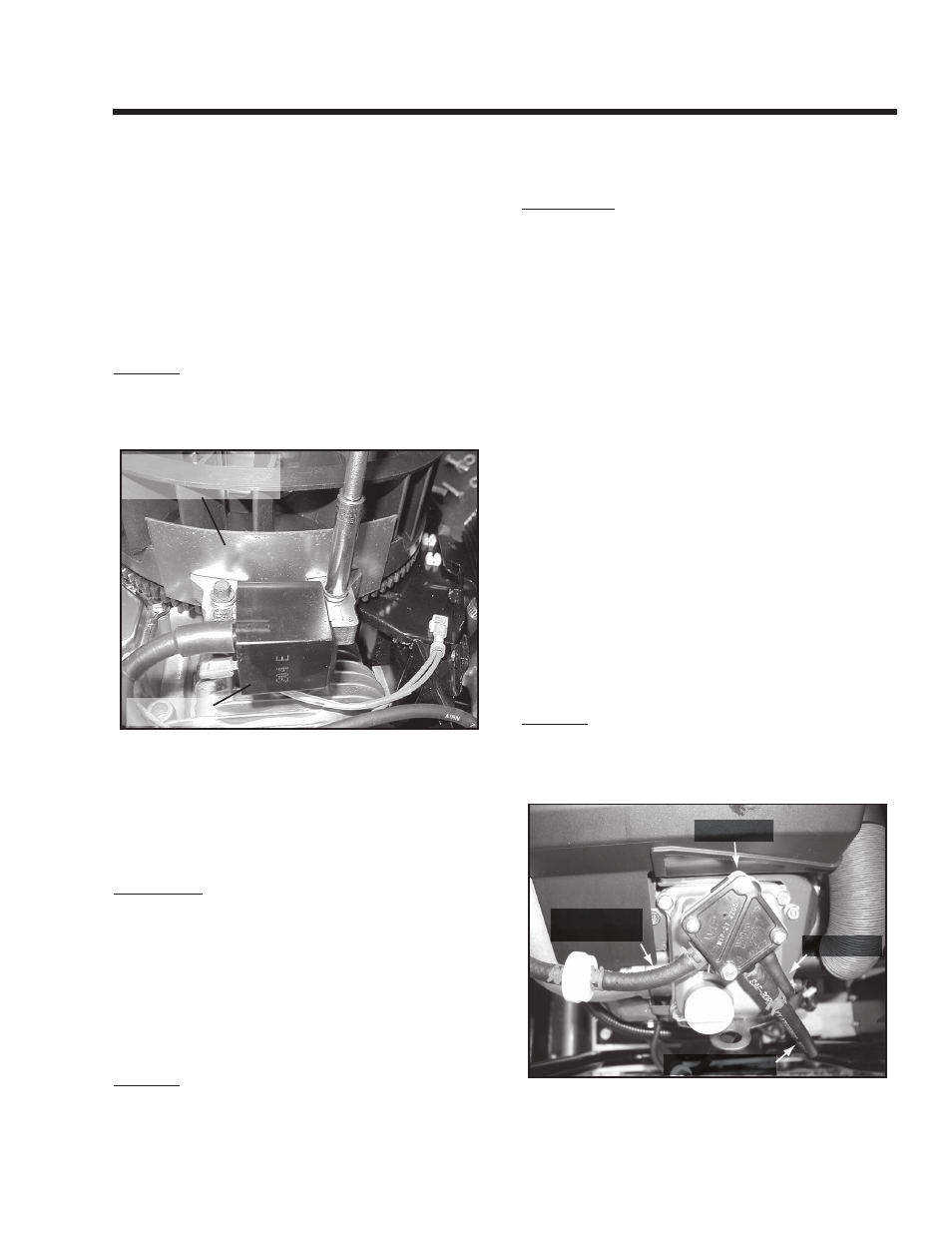

0.008-0.012" GAUGE

(0.203-0.304 mm)

MAGNETO

Figure 6-49. – Setting Ignition Magneto (Armature)

Air Gap

TEST 36 - TEST FUEL SHUTOFF SOLENOId

(FSS)

PROCEDURE

1. Disconnect Wire 16 from the Starter Contactor (SC) located on

the starter motor.

2. Remove the air cleaner cover.

3. Place the Start-Run-Stop Switch (SW1) to STOP then to

START. When SW1 is activated a click should be heard and

or activation of the Fuel Shutoff Solenoid should be felt. It can

then be assumed that the Fuel Shutoff Solenoid is functioning.

RESULTS:

Refer to flow chart.

TEST 37: TEST FUEL SHUTOFF SOLENOId

VOLTAgE

PROCEDURE:

1. Set a voltmeter to measure DC voltage.

2. Disconnect the two pin connector from the Fuel Shutoff

Solenoid (FSS).

3. Connect the positive meter test lead to the red wire. Connect

the negative meter test lead to the black wire. Place the Start-

Run-Stop switch (SW1) to START. During cranking, 12 VDC

should be measured. If DC voltage is not measured continue

testing.

4. Set a voltmeter to measure resistance.

5. Connect one meter test lead to the black wire. Connect the

other meter test lead to frame ground. Continuity should be

measured. If continuity is not measured repair or replace the

black ground wire or correct poor ground connection.

6. Set a voltmeter to measure DC voltage.

7. Remove Wire 14 from the Start-Stop Relay (SSR). Refer to

Figure 6-41 on Page 54. Connect the positive meter test lead

to the terminal of the SSR that Wire 14 was just removed.

Connect the negative meter test lead to frame ground. Place

the Start-Run-Stop Switch (SW1) to the start position. 12 VDC

should be measured. If 12 VDC is measured repair or replace

Wire 14 between the SSR and Resistor 1 or between Resistor

1 and the FSS.

RESULTS:

Refer to flow chart.

TEST 38 - CHECk FUEL PUMP

FUEL PUMP

FUEL TO

CARBURETOR

FUEL FROM TANK

PULSE LINE

Figure 6-50. – Fuel Pump and Fuel Lines