Guardian Technologies 5209 User Manual

Page 11

section 3

DescRiption & coMponents

INTROdUCTION

The generator revolving field (rotor) is driven by an

air-cooled engine at about 3600 rpm.

The generator may be used to supply electrical power

for the operation of 120 and/or 240 volts, 1-phase, 60

Hz, AC loads.

ENgINE-gENERATOR dRIVE SYSTEM

The generator revolving field is driven by an air-

cooled, horizontal crankshaft engine. The generator is

directly coupled to the engine crankshaft (see Figure

1). Both the engine and generator rotor are driven at

approximately 3600 rpm, to provide a 60 Hz AC out-

put.

THE AC gENERATOR

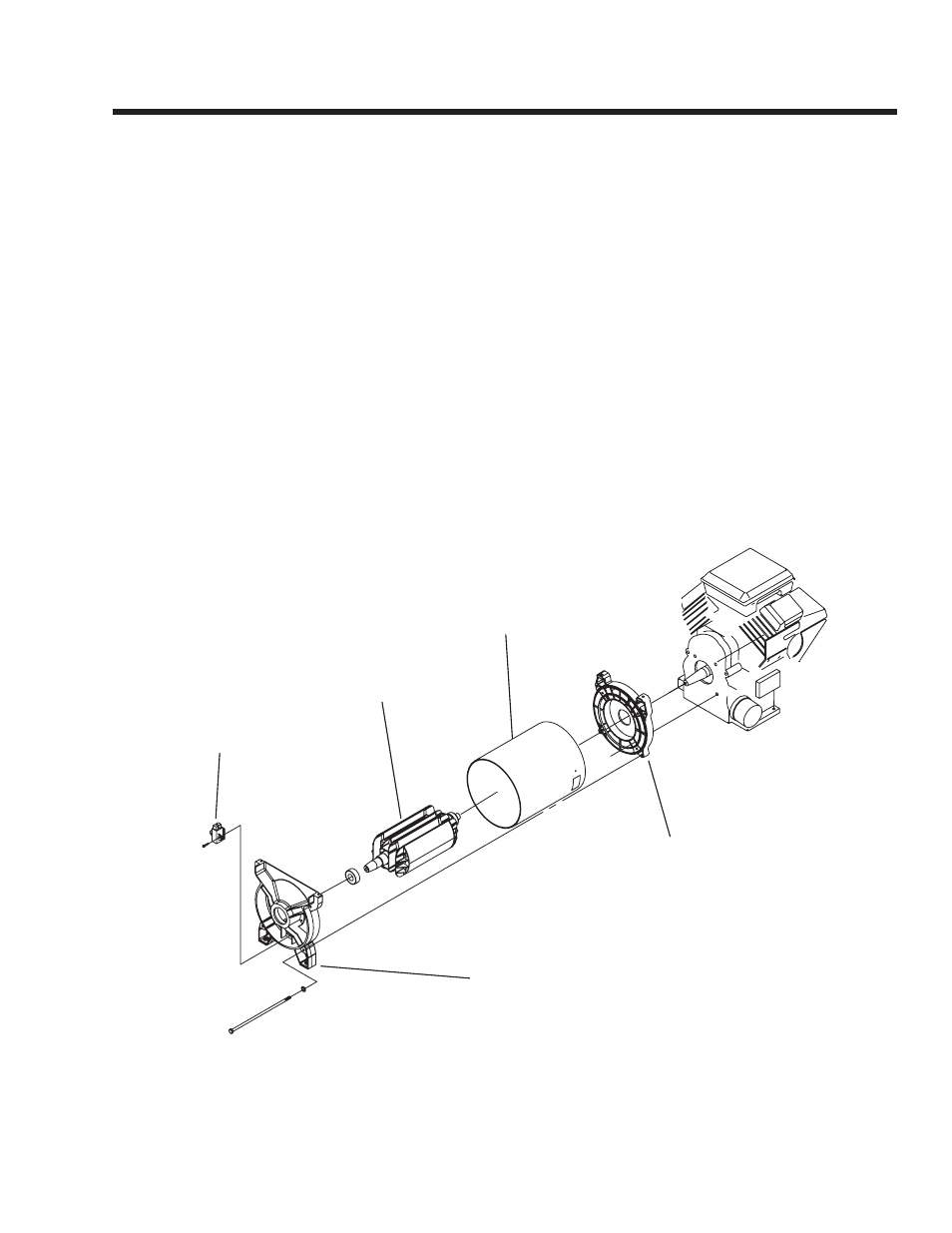

Figure 3-1 shows the major components of the AC

generator.

ROTOR ASSEMbLY

The 2-pole rotor must be operated at 3600 rpm to

supply a 60 Hertz AC frequency. The term “2-pole”

means the rotor has a single north magnetic pole and

a single south magnetic pole. As the rotor rotates, its

lines of magnetic flux cut across the stator assem-

bly windings and a voltage is induced into the stator

windings. The rotor shaft mounts a positive (+) and

a negative (-) slip ring, with the positive (+) slip ring

nearest the rear bearing carrier (Figure 3-2). The rotor

bearing is pressed onto the end of the rotor shaft. The

tapered rotor shaft is mounted to a tapered crankshaft

and is held in place with a single through bolt.

Page 9

STATOR

ENGINE

ENGINE

ADAPTOR

REAR BEARING

CARRIER

BRUSH HOLDER

ASSEMBLY

ROTOR

Figure 3-1. – AC Generator Exploded View