Guardian Technologies 5209 User Manual

Page 48

section 6

Diagnostic tests

Page 46

BRUSHES

Figure 6-21. – Brush Location

2. Remove Wire 4 from the positive (+) brush terminal.

3. Remove the ground wire (0) from the negative (-) brush.

4. Remove the brush holder, with brushes.

5. Inspect the brushes for excessive wear, damage, cracks, chip-

ping, etc.

6. Inspect the brush holder, replace if damaged.

7. Inspect the slip rings.

a. If slip rings appear dull or tarnished they may be

cleaned and polished with fine sandpaper. DO

NOT USE ANY METALLIC GRIT TO CLEAN

SLIP RINGS. (A 400 grit wet sandpaper is rec-

ommended).

b. After cleaning slip rings, blow away any sandpa-

per residue.

RESULTS:

1. Replace bad brushes. Clean slip rings, if necessary.

2. If brushes and rings are good, go to Test 14.

TEST 14 - CHECk ROTOR ASSEMbLY

PROCEDURE:

Gain access to the brushes and slip rings. Disconnect

Wire 4 and Wire 0 from their respective brushes and

remove the brush holder. Then, test the Rotor as fol-

lows:

1. Set a voltmeter to measure resistance.

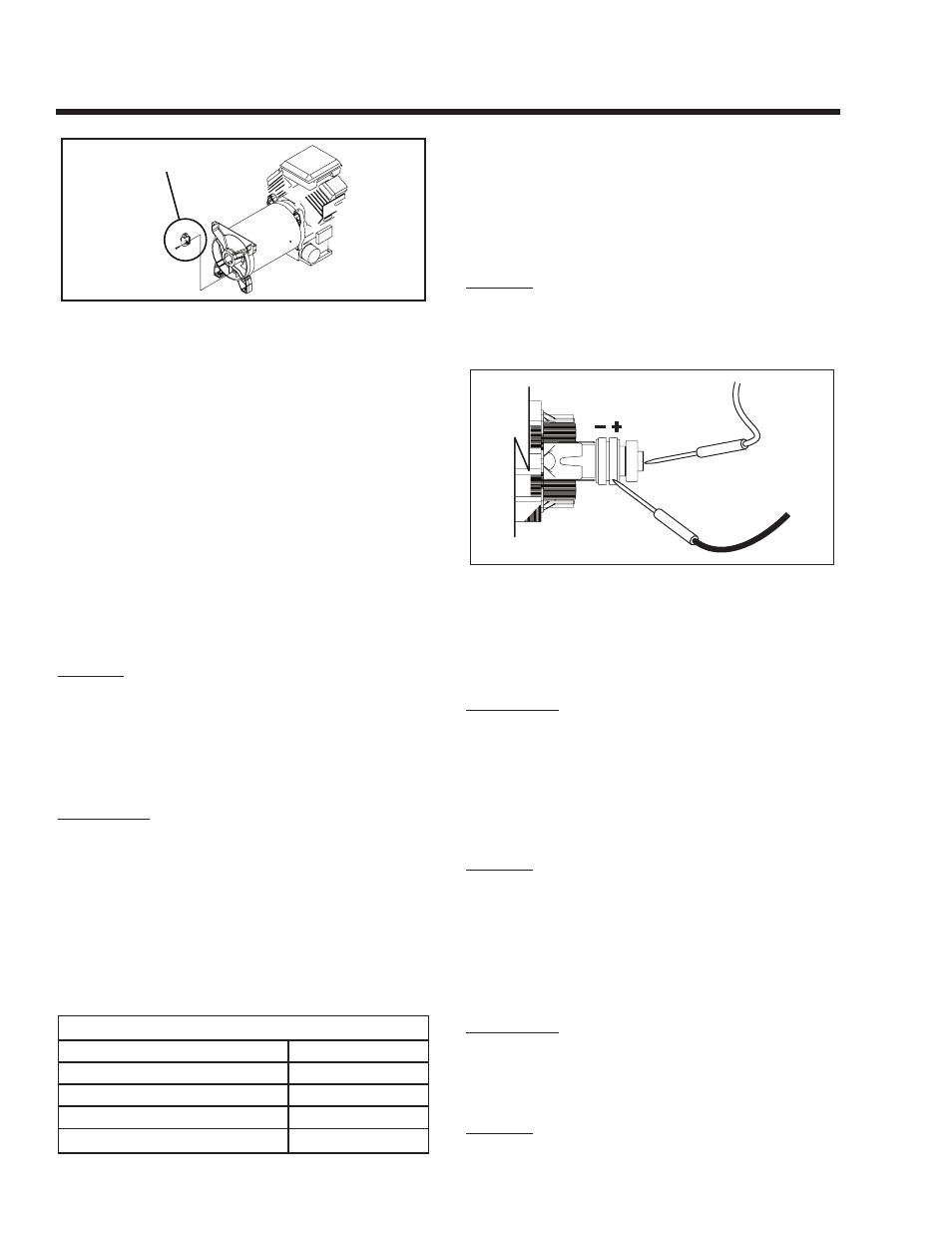

2. Connect the positive (+) meter test lead to the positive (+) slip

ring (nearest the Rotor bearing). Connect the common (-) test

lead to the negative (-) slip ring. Read the resistance of the

Rotor windings, in OHMS.

ROTOR RESISTANCE

*

MoDel:

oHMs

004451-0 004986-0

7.01Ω

004582-0,1 004987-0 005209-0

7.71Ω

004582-2 004987-1

13.1Ω

004583-0 005308-0

14.2Ω

* Resistance values in ohms at 20° C. (68° F.). Actual readings

may vary depending on ambient temperature. A tolerance of plus

or minus 5% is allowed.

3. Connect the positive (+) meter test lead to the positive (+) slip

ring, the common (-) test lead to a clean frame ground (such as

the Rotor shaft). The meter should read INFINITY.

RESULTS:

1. Replace the Rotor if it fails the test.

2. If Rotor checks good, perform “Rotor Insulation Resistance

Test,” on Page 15.

POSITIVE (+)

TEST LEAD

Figure 6-22. – Testing at Slip Rings

TEST 15 - CHECk LOAd VOLTAgE &

FREqUENCY

PROCEDURE:

Perform this test in the same manner as Test 1, but

apply a load to the generator equal to its rated capac-

ity. With load applied check voltage and frequency.

Frequency should not drop below about 59 Hertz with

the load applied.

Voltage should not drop below about 235 VAC with

load applied.

RESULTS:

1. If voltage and/or frequency drop excessively when the load is

applied, go to Test 16.

2. If load voltage and frequency are within limits, end tests.

TEST 16 - CHECk LOAd WATTS & AMPERAgE

PROCEDURE:

Add up the wattages or amperages of all loads pow-

ered by the generator at one time. If desired, a clamp-

on ammeter may be used to measure current flow.

See “Measuring Current” on Page 7.

RESULTS:

1. If the unit is overloaded, reduce the load.