Schedule, Lubrication, Cleaning – Grizzly G1095/G1096 User Manual

Page 24

-22-

Model g1095/g1096 1-hp power Feeder

SEctiON 5: MaiNtENaNcE

always disconnect power

to the machine before

performing maintenance.

Failure to do this may

result in serious person-

al injury.

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily check:

•

loose mounting bolts.

•

damaged wheels.

•

Worn or damaged, switch, cord, and plug.

•

Any other condition that could hamper the

safe operation of this power feeder.

Schedule

Cleaning the Model g1095/g1096 is relatively

easy. Frequently blow-off sawdust with com-

pressed air. this is especially important for the

internal working parts and motor. dust build-up

around the motor is a sure way to decrease its

lifespan. if the wheels become loaded up with

pitch, oil, or other residues, wipe them clean using

a clean rag and a mild solvent. Avoid touching

the plastic or paint with mineral spirits or you may

damage the surfaces.

Lubrication

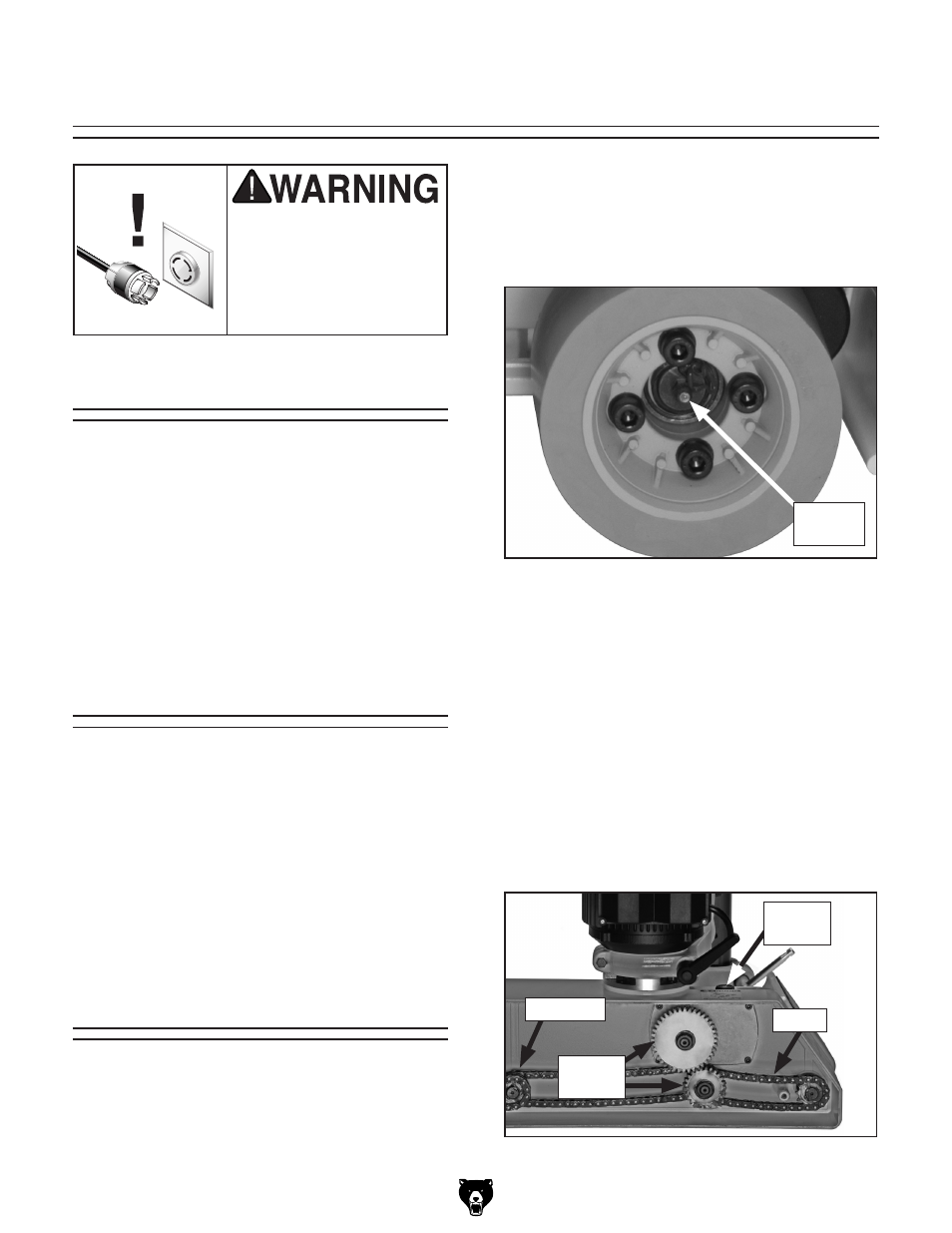

•

every 40 hours of use, or once every two

weeks, wipe clean and lubricate the wheel

grease fittings (

Figure 15) with one pump of

an automotive grade multipurpose grease. do

not get any grease on the rubber wheels.

Figure 15. Wheel lubrication.

grease

Fitting

Figure 16. lubrication locations.

sprocket

Chain

Change

gears

oil Fill

port

cleaning

•

to prevent surface rust and binding,

periodically clean and oil all lock lever and

leadscrew threads with a light machine oil.

•

After the first month or 200 hours of use,

change the gearbox oil with 5.1 fluid ounces

of an automotive grade 80-90W gear oil. to

drain the unit, remove the fill plug labeled

"

OiL" (Figure 16) and invert the power feed-

er. For the remaining life of the power feeder,

change the oil every 6 months or 1000 hours

of use.

•

to prevent rust and binding, paint the sprock-

ets, chain, and change gears (

Figure 16)

with a light film of an automotive grade multi-

purpose grease.