Generac Power Systems Recreational Vehicle Generator 5413 User Manual

Page 59

Section 7

DIAGNOSTIC TESTS

3. If “Infinity” was not measured in Step 15, repair

or replace grounded Wire 18A between the j1

Connector and the insulated terminal stud or

defective insulated terminal stud.

4. If sparking still does not occur after adjusting the

armature air gap, testing the ground wires and

performing the basic flywheel test, replace the

ignition magneto(s).

Note: Before replacing the Ignition Magneto, check

the Flywheel Magnet.

CHECkING FLYWHEEL MAGNET:

The flywheel magnet rarely loses its magnetism. If you

suspect a magnet might be defective, a rough test can

be performed as follows:

1. Place the flywheel on a wooden surface.

2. Hold a screwdriver at the extreme end of its han-

dle and with its point down.

3. Move the tip of the screwdriver to about 3/4 inch

(19mm) from the magnet. The screwdriver blade

should be pulled in against the magnet.

FLYWHEEL kEY:

In all cases, the flywheel taper is locked on the crank-

shaft taper by the torque of the flywheel nut. A keyway

is provided for alignment only and theoretically carries

no load.

If the flywheel key becomes sheared or even partially

sheared, ignition timing can change. Incorrect timing

can result in hard starting or failure to start.

Remove and inspect flywheel key for damage.

TEST 32 – CHECk VALVE AdJUSTMENT

DISCUSSION:

The valve lash must be adjusted correctly in order to pro-

vide the proper air/fuel mixture to the combustion chamber.

ADjUSTING VALVE CLEARANCE:

Adjust valve clearance with the engine at room tem-

perature. The piston should be at top dead center

(TDC) of its compression stroke (both valves closed).

An alternative method is to turn the engine over and

position the intake valve fully open (intake valve spring

compressed) and adjust the exhaust valve clearance.

Turn the engine over and position the exhaust valve

fully open (exhaust valve spring compressed) and

adjust the intake valve clearance.

Correct valve clearance is given below, in INCHES

(MILLIMETERS).

Intake valve

0.002-0.004 (0.05-0.1)

Exhaust valve

0.002-0.004 (0.05-0.1)

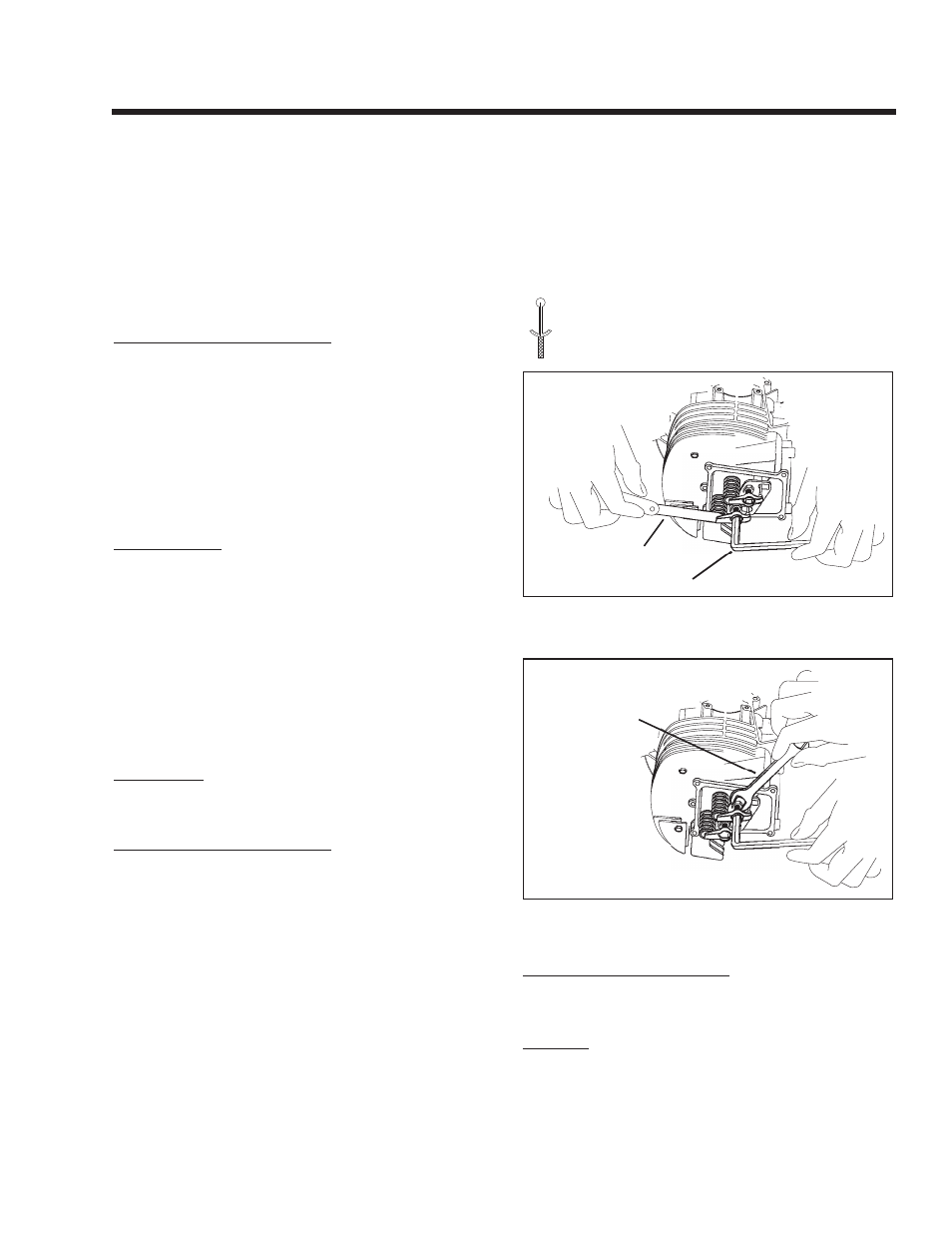

1. Loosen the rocker arm jam nut. Use a 10mm allen

wrench to turn the pivot ball stud while checking the

clearance between the rocker arm and valve stem

with a feeler gauge (see Figure 7-39).

2. When clearance is correct, hold the pivot ball stud

with the allen wrench and tighten the rocker arm

jam nut to the specified torque with a crow’s foot.

After tightening the jam nut, recheck valve clear-

ance to make sure it did not change.

TORQUE SPECIFICATION

ROCKER ARM JAM NUT

174 inch-pounds

FEELER GAUGE

ALLEN WRENCH

Figure 7-39 – Adjusting Valve Clearance

CROW'S FOOT

Figure 7-40 – Tightening the Jam Nut

INSTALL ROCkER ARM COVER

1. Use a new rocker arm cover gasket. Install the

rocker arm cover and retain with four screws.

RESULTS:

Adjust valves to specification and retest. If problem

continues, go to Test 35.

Page 57