Generac Power Systems Recreational Vehicle Generator 5413 User Manual

Page 38

Section 7

DIAGNOSTIC TESTS

INTROdUCTION

The “Diagnostic Tests” in this chapter may be per-

formed in conjunction with the “Flow Charts” of

Section 6. Test numbers in this chapter correspond to

the numbered tests in the “Flow Charts”.

Tests 1 through 13 are procedures involving problems

with the generator’s AC output voltage and frequency

(Problems 1 through 3 in the “Flow Charts”).

Tests 14 through 41 are procedures involving prob-

lems with engine operation (Problems 3 through 10 in

the “Troubleshooting Flow Charts”).

You may wish to read Section 4, “Measuring

Electricity”.

NOTE: Test procedures in this Manual are not nec-

essarily the only acceptable methods for diagnos-

ing the condition of components and circuits. All

possible methods that might be used for system

diagnosis have not been evaluated. If you use

any diagnostic method other than the method

presented in this Manual, you must ensure that

neither your safety nor the product’s safety will be

endangered by the procedure or method you have

selected.

TEST 1 – CHECk NO-LOAd VOLTAgE ANd

FREqUENCY

DISCUSSION:

The first step in analyzing any problem with the AC

generator is to determine the unit’s AC output volt-

age and frequency. Once that has been done, you will

know how to proceed with specific diagnostic tests.

PROCEDURE:

1. Set a volt-ohm-milliammeter (VOM) to read AC

voltage. Connect the meter test leads across cus-

tomer connection leads T1 (Red) and T2 (White).

2. Disconnect or turn OFF all electrical loads. Initial

checks and adjustments are accomplished at no-

load.

3. Start the engine, let it stabilize and warm up.

4. Read the AC voltage.

5. Connect an AC frequency meter across AC output

leads T1 (Red) and T2 (White). Repeat the above

procedure.

RESULTS:

For units rated 60 Hertz, no-load voltage and fre-

quency should be approximately 122-126 VAC and

60.0-60.5 Hertz respectively.

1. If AC voltage and frequency are BOTH corre-

spondingly high or low, go to Test 2.

2. If AC frequency is good but low or residual volt-

age is indicated, go to Test 4.

3. If AC output voltage and frequency are both “zero”,

go to Test 11.

4. If the no-load voltage and frequency are within the

stated limits, go to Test 12.

NOTE: The term “low voltage” refers to any voltage

reading that is lower than the unit’s rated voltage.

The term “residual voltage” refers to the output

voltage supplied as a result of Rotor residual

magnetism (approximately 5-12 VAC).

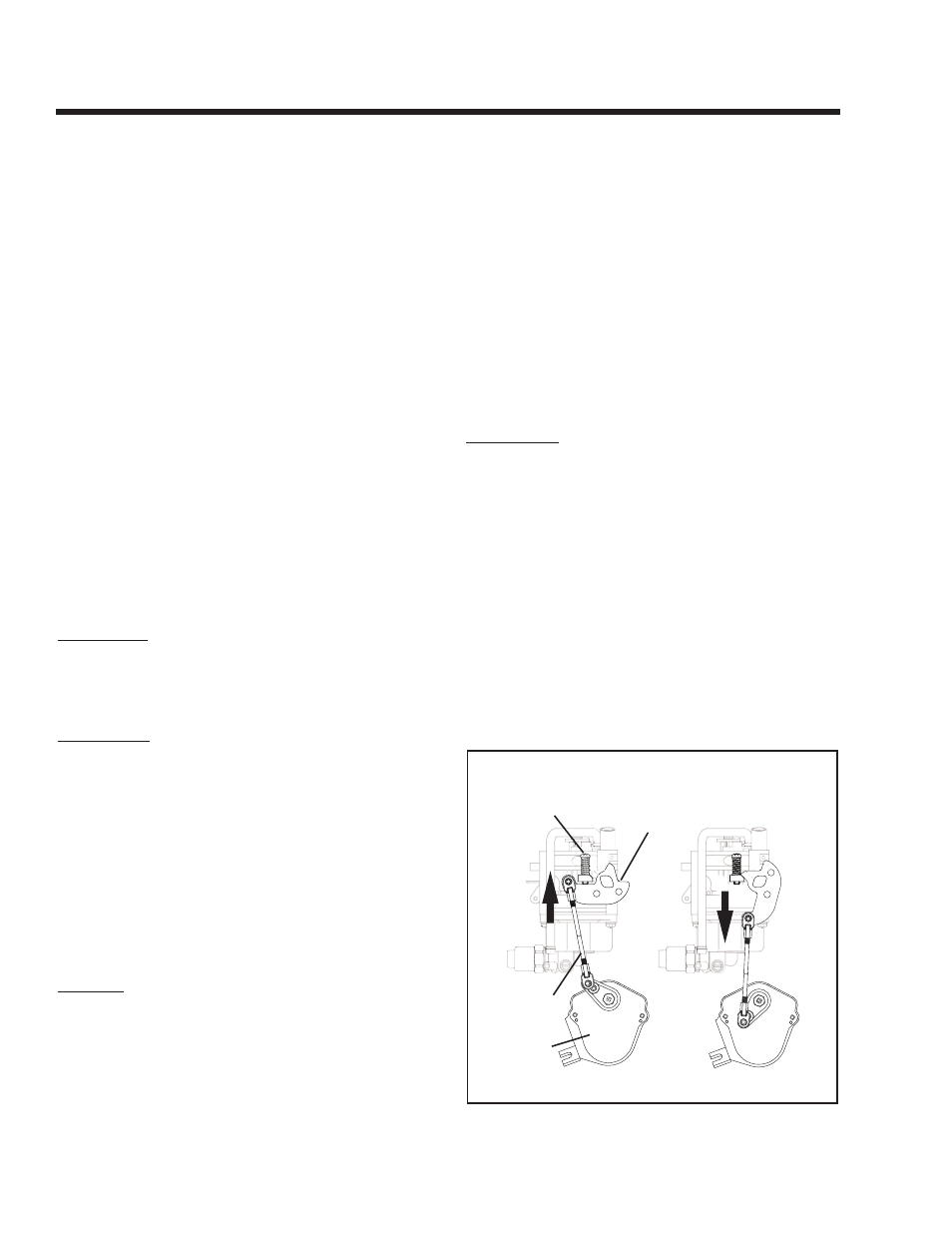

TEST 2 – CHECk STEPPER MOTOR CONTROL

*

Caution! Do not stand in front of carburetor

when checking the stepper motor movement

due to possible backfire from the carburetor.

PROCEDURE:

1. Remove air cleaner cover to access stepper

motor.

2. Physically grab the throttle and verify the stepper

motor, linkage and throttle do not bind in any way.

If any binding is felt, repair or replace components

as needed. Some resistance should be felt as the

stepper motor moves through it’s travel.

3. Physically move the throttle to the closed position

by pulling the stepper motor arm towards the idle

stop.

a. Press the Start-Stop switch (SW1) to “START”

and watch for stepper motor movement. It should

move to the wide open (down) position during

cranking. Once the unit starts the stepper motor

should move the throttle to a position to maintain

60.0-60.5 Hertz.

THROTTLE

ARM

IDLE

STOP

UP

CLOSED

DOWN

OPEN

THROTTLE

LINKAGE

STEPPER

MOTOR

Figure 7-1. Throttle Position

Page 36