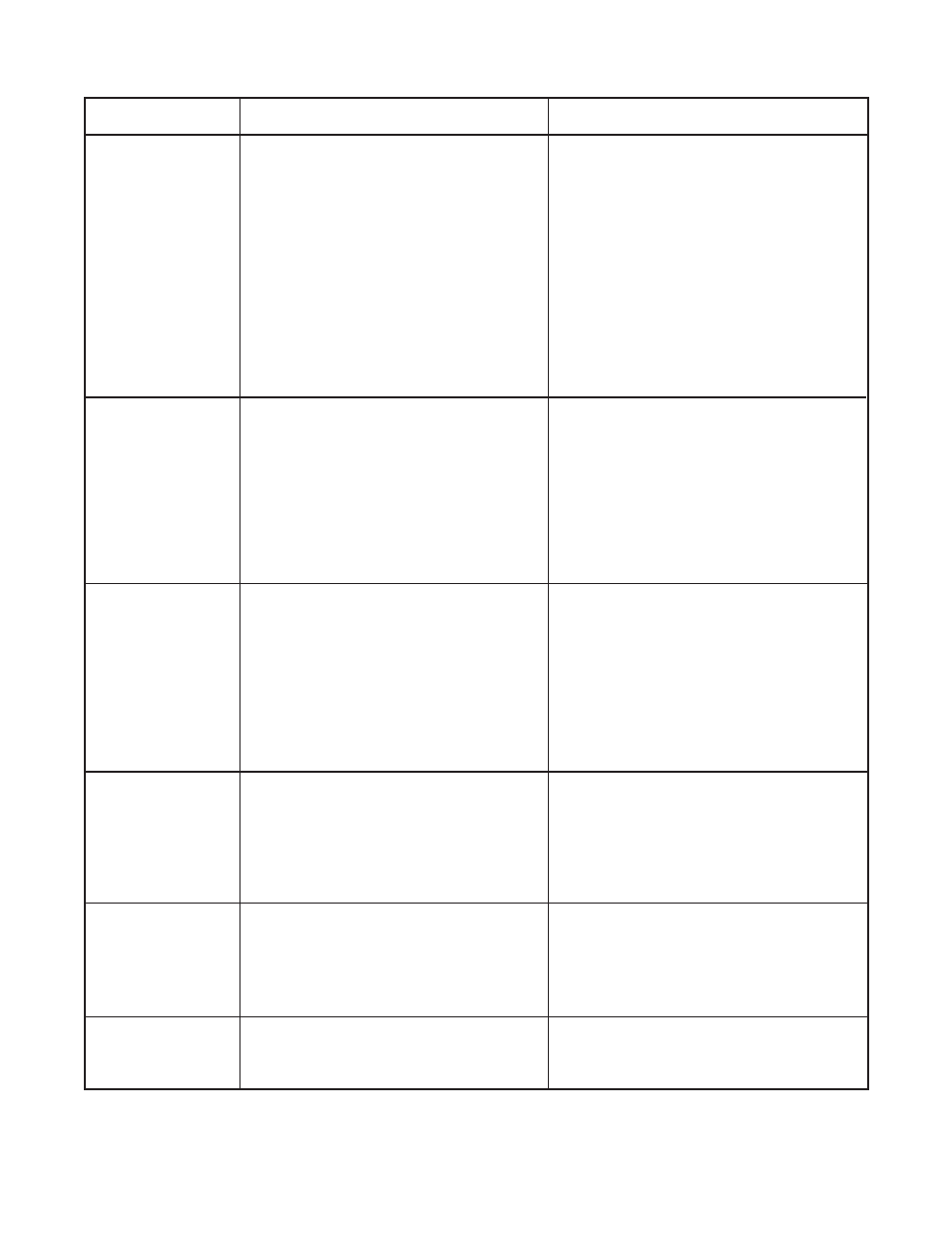

Icemaker troubleshooting chart – Follett C/E12CI400A User Manual

Page 27

27

Icemaker troubleshooting chart

Indicators/possible cause

1. Kink in ice transport tube.

2. Bin level control remains in closed

position.

3. Ice transport tube ruptured internally.

4. Worn evaporator bearings.

5. Faulty gearmotor start relay. Icemaker

torques out within 5 seconds of start-up.

6. Torque out occurs when storage bin fills

to capacity.

1. Gearmotor running but no output

rotation.

2. Float reservoir empty.

3. Air bubble in water supply line. Water in

reservoir but not in evaporator.

1. High pressure cut-out open due to high

head pressure.

2. Clogged or dirty condenser coil.

3.

Improper

ventilation.

4.

Defective

compressor.

1. Clogged or dirty condenser coil.

2. Compressor not pumping.

3. Low refrigerant charge.

1. Compressor switch in OFF position.

2. No output on compressor and fan motor

terminals on control board.

3. Failed fan motor causes high pressure

cut-out to open.

1. Mineral build-up on evaporator surface.

Corrective action

1. Eliminate kink and check that tube

routing complies with Follett icemaker

installation manual.

2. Adjust or replace control.

3. Replace complete run of ice transport

tube.

4. Inspect bearings for roughness or

binding and replace if necessary.

5. Replace gearmotor start relay.

6. Ensure that ice contacts bin thermostat

before backing ice up in transport tube.

Refer to dispenser manual for proper

thermostat and ice tube mounting.

1. Check for broken gearmotor output shaft

or damaged gearbox.

2. Check for defective water sensor (water

OK (WTR) LED remains on even when

float empty or probe removed from

water).

3. Purge air from line.

1 Check discharge pressure and adjust

water regulator valve.

2. Clean condenser coil.

3. Provide inlet and exhaust air provisions

per Follett icemaker installation manual.

4. Replace compressor.

1. Clean condenser coil.

2. Replace compressor.

3. Check for leaks; repair, evacuate, and

weigh in correct charge.

1. Turn compressor switch on.

2. Replace control board.

3. Replace fan motor.

1. Clean evaporator with liquid IM cleaner.

Problem

6. Icemaker runs

for short period

of time and shuts

down on torque

error.

System

status:

20M or 2nd LED

are lit.

7.

Evaporator

is

iced up on the

outside. No ice

production.

System

status:

compressor,

gearmotor

and fan motor

running.

8. Compressor

cycles

intermittently.

System

status:

gearmotor and

fan motor run.

9. Unit runs but not

making ice.

System

status:

compressor,

gearmotor & fan

motor running.

10. Compressor and

fan motor will not

run. Gearmotor

runs.

11. Intermittent

noises from

evaporator.