Harbor Freight Tools DUAL MIG 93793 User Manual

Page 12

Page 12

For technical questions, please call 1-800-444-3353.

SKU 93793

to route the Wire

nOte: When installing wire of a different size or composition, you will also need to change

wire settings, set the gun polarity, and, possibly, install a gas cylinder. See pages 15-17.

1.

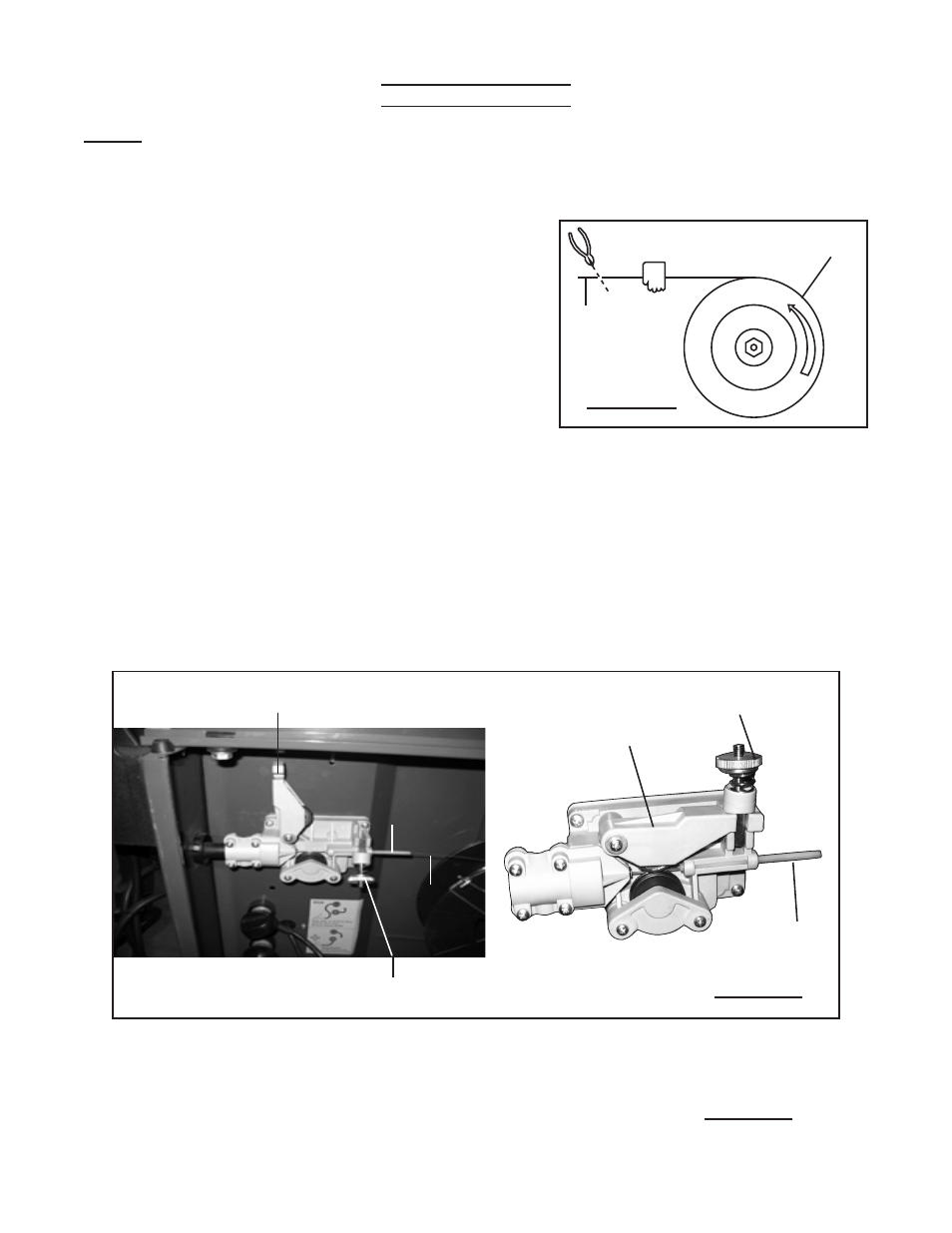

IMpOrtant: Securely hold onto the end of the Welding Wire and keep tension on it

during the following steps. If this is not done the

Welding Wire will spring backward, creating a

tangled “bird’s nest” and resulting in wasted wire.

(See Figure D.)

Hold the Welding Wire securely while you cut

2.

enough Wire off the end of the Spool to remove

all bent and crimped Wire. Make sure the cut end

has no burrs or sharp edges (cut again, if needed).

(See Figure D.)

Loosen and lower the Tension Adjusting Knob (15b) on the Wire Feed Assembly. Then,

3.

raise the Swing Arm (15a).

(See Figure e.)

Keep tension on the Welding Wire, and guide at least 12 inches of Wire into the Wire

4.

Feed Leader (15f).

(See Figure e.)

Lower the Swing Arm (15a) on the Wire Feed Assembly. Lower and tighten the Tension

5.

Adjusting Knob (15b). Once the Wire is held in place, you may release it.

(See Figure

e.)

SpOOl

WelDInG

WIre

FIGure D

SWInG arM

(15a)

SWInG arM

(15a)

tenSIOn aDJuStInG KnOB

(15b)

tenSIOn aDJuStInG KnOB

(15b)

WIre FeeD

leaDer

(15f)

WIre FeeD

leaDer

(15f)

WIre

FIGure e

Lay the Torch Cable out in a straight line so that the Welding Wire moves through it easily.

6.

Leave the Access Panel (31) of the Welder open so that the Wire Feed Assembly can be

observed.

Remove the Gun Nozzle (51a) and Contact Tip (51b).

7.

(See Figure F, next page.)