Diagnostics, Beacon ii troubleshooting guide (continued), Problem step action item if ok if not ok – Heatcraft Refrigeration Products BEACON II H-IM-79E User Manual

Page 26

26

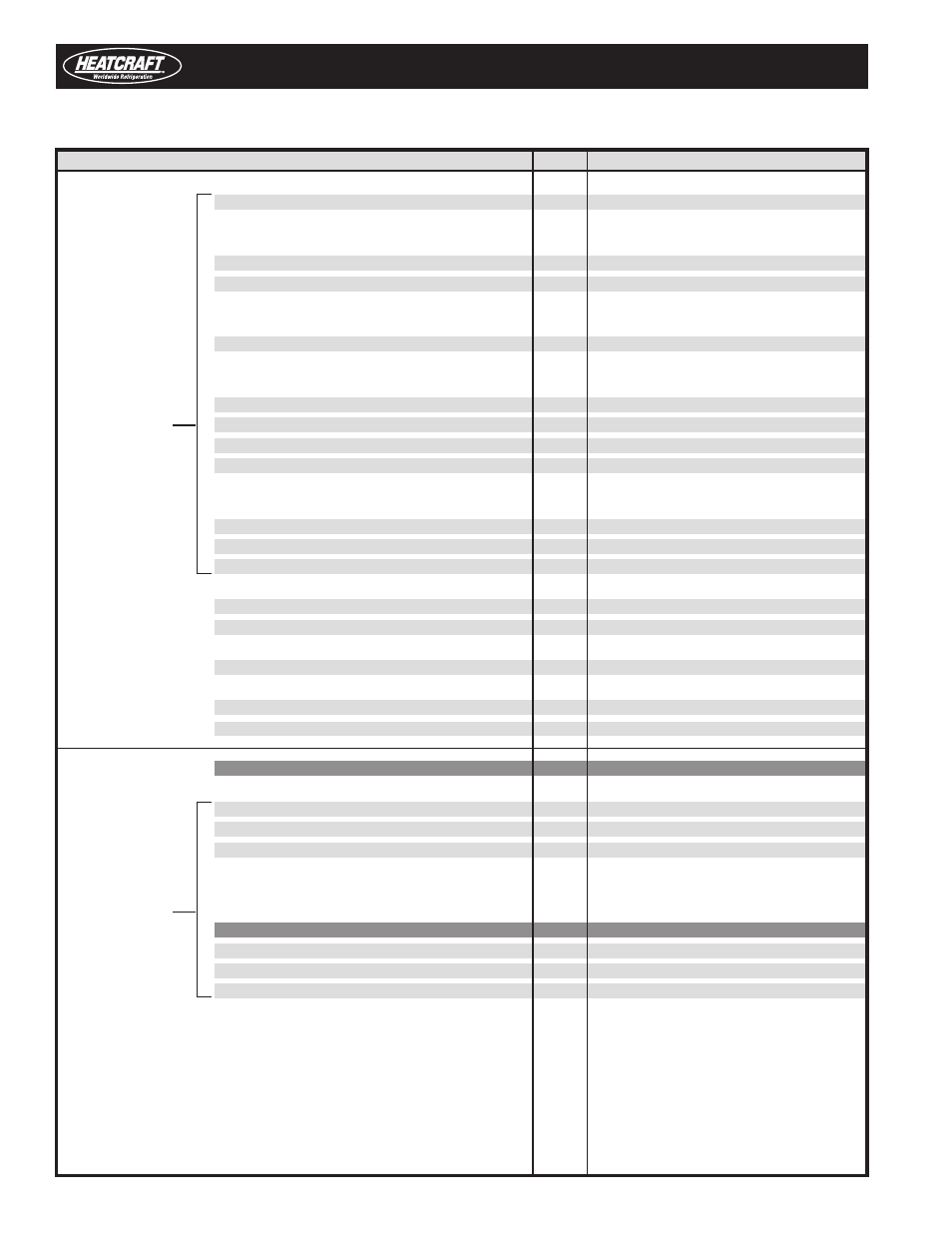

Beacon II Troubleshooting Guide (continued)

Diagnostics

PROBLEM

Step ACTION ITEM

IF OK IF NOT OK

1. Check system operation: Is it running?

1. Check power to condensing unit

Check position of Service Mode switches

Check compressor overloads and contactor

2. Check system charge

2. Add or remove refrigerant to proper charge

3. Check for proper operating superheat

3. Check EEV operation

Check control board EEV signal

Check suction sensor and transducer

4. Check for high superheat and EEV wide open

4. Check EEV inlet screen and restrictions

Check liquid line sizing

Check head pressure controls

5. Check Low Pressure Safety Switch

5. Check everything for E7 LPS above

Cannot get to box

6. Compare equipment capacity with requirements

Go to

6. Add or replace with more/larger equipment

temperature

7. Check box temperature setpoint

next step 7. Correct setpoint to proper value

8. Check compressor performance

8. Check compressor application limitations

Check integrity of compressor operation

(impaired, worn or damaged components)

9. Check condenser coil for dirt/debris

9. Clean condenser coil

10. Check condenser for non-condensables

10. Remove all non-condensables

11. Check condenser fan operation

11. Replace/repair fan blade, motor, cycling

switch or make corrective adjustments.

12. Check for correct refrigerant type

12. Compare board setpoint and refrigerant

13. Check for iced evaporator coil

13. Defrost coil and check defrost cycle (see E2)

settings/setpoints and defrost sensor

14. Check defrost parameters

14. Correct defrost setpoints in program

(frequency and termination of defrosts)

15. Check superheat setpoint (too high?)

15. Correct setpoint for more cooling surface

16. Check display values (°F or °C)

16. Correct setpoint for proper display values

Placing system into SERVICE MODE

Terminating SERVICE MODE

(BOARDS ONLY)

(BOARDS ONLY)

1. Use Remote Service Switch in condensing unit

1. Must terminate using same switch

2. Pressing “Force Service” button board* twice

2. Press “Clear” button on board

3. Connection between “Ser” and “C” on board*

3. Open connection between “Ser” and “C”

(all are wired in parallel; all will activate mode)

(Note: If multiple switches were placed in Service

Service Mode

*ONLY Master board on multiple evaporator systems

Mode, all must be “open” to terminate the mode.)

(

SEr is displayed)

(with Beacon II Smart Controller)

(with Beacon II Smart Controller)

1. Use Remote Service Switch in condensing unit

1. Must terminate using same switch

2. Connection between “Ser” and “C” on board*

2. Open connection between “Ser” and “C”

3. From program menu of Beacon II Smart Controller,

3. From program menu of Beacon II Smart Controller,

Change SERVICE setpoint to “On”.

Change SERVICE setpoint to “Off”

[all are wired in parallel; any/all will activate mode.]

[Note: If multiple switches were placed in Service

*ONLY Master board on multiple evaporator systems

Mode, all must be “open” to terminate the mode.)