Diagnostics expansion valve capacity, Beacon ii troubleshooting guide – Heatcraft Refrigeration Products BEACON II H-IM-79E User Manual

Page 23

23

Beacon II Troubleshooting Guide

Diagnostics

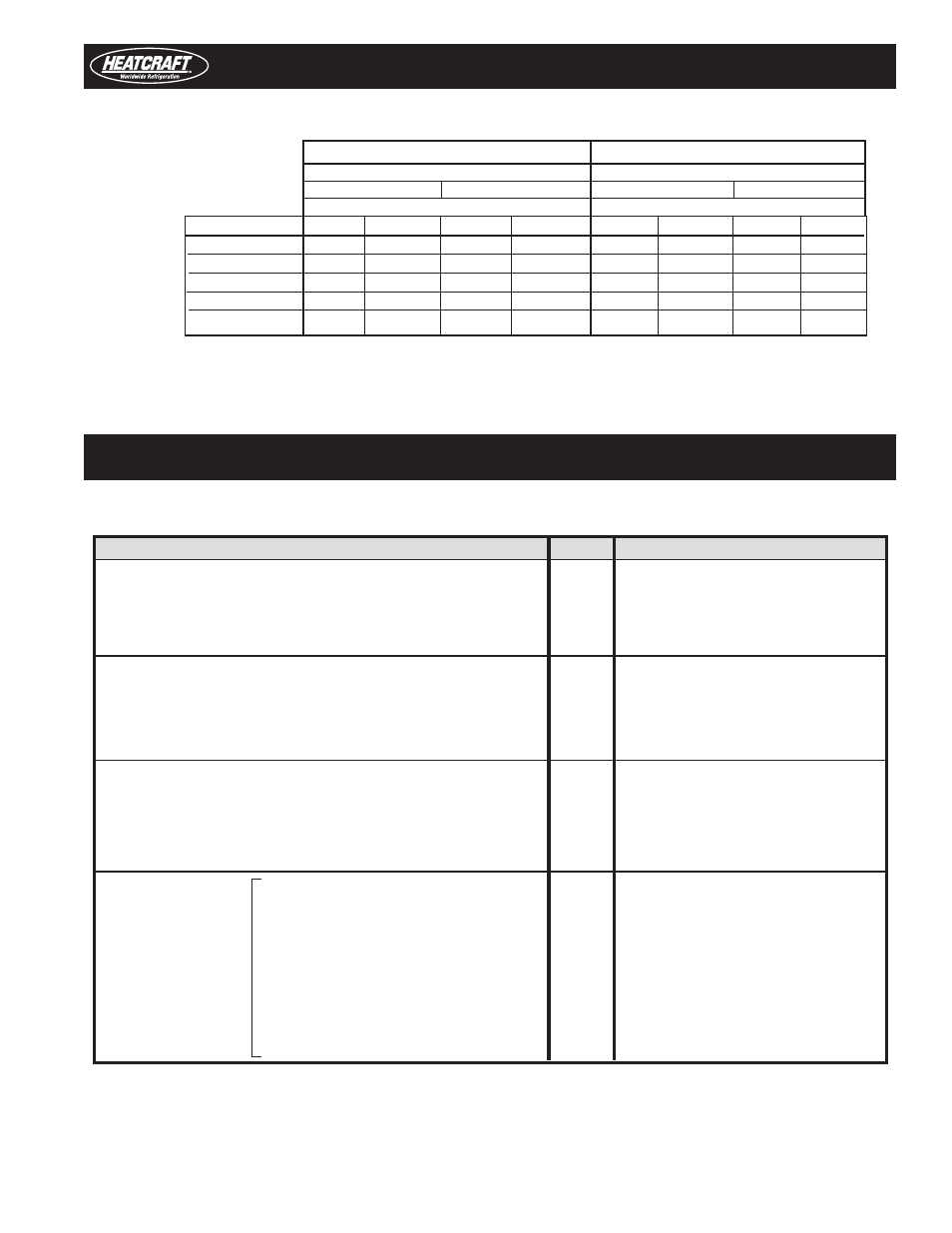

Expansion Valve Capacity

Part Number

100

BTUH

100

BTUH

100

BTUH

100

BTUH

29326101

0.44

5220

0.41

4920

0.31

3690

0.27

3230

29326201

4.25

51000

4.00

47900

3.00

36000

2.67

32000

29326401

8.02

90240

7.54

90480

5.65

67800

5.01

60120

29326501

15.13

181680

14.25

171000

10.69

128280

9.47

113640

29326601

22.18

266160

20.87

250440

15.65

187800

13.86

166320

R-22

R-404A / R-507

Evaporator Temperature (°F.)

Evaporator Temperature (°F.)

+20

-20

+20

-20

Pressure Drop Across Valve (psi)

Pressure Drop Across Valve (psi)

PROBLEM

Step ACTION ITEM

IF OK

IF NOT OK

1.

Check Primary Power Supply Disconnect

1. Check fuses and circuit breakers

2.

Check Voltage to Evaporator Transformer

Go to

2. Check field wiring for breaks

LED is not lit.

3.

Check Transformer Secondary Output Volts next step

3. Replace if necessary

4.

Check Voltage at Control Board (24V and C)

4. Check factory wiring and connections

5.

Replace Control Board

1.

Check Compressor internal overloads

1. Wait for reset

2.

Check Control Power to Condensing Unit

2. Check transformer voltage (secondary and

LED shows

Coo, but

(24 Volts across “COMP” and “C” at board)

Go to

primary) and wiring of 208V power taps.

compressor will not run.

3.

Check Compressor Contactor Coil Voltage

next step

3. Check internal condensing unit wiring

4.

Check Compressor Contactor “pulled in”

4. Replace as needed

ERROR CODES:

E1 Room Sensor

Check Sensor and Board Connection

Replace as needed

E2 Defrost Sensor

Check Sensor and Board Connection

Replace as needed

E3 Suction Sensor

Check Sensor and Board Connection

Replace as needed

E4 Suction Transducer

Check Transducer and Board Connection

Replace as needed

E5 Outdoor Sensor

Check Sensor, wiring and Board Connection

Replace or remove

1.

Check Refrigerant Type

1. Compare board setpoint and refrigerant

2.

Check coil for ice

2. Defrost coil and check defrost cycle

settings/setpoints, defrost sensor and

heater amps.

E6 Low Superheat

3.

Check Control Board step position from

3. Replace board if EEV steps not at 2.

During Cooling

board LED

Go to

4. Pumpdown system see if LPS opens or if it

(0°F for 2 minutes)

4.

Check Electric Expansion Valve Closure

next step

times out (EEV is bad or LPS is set

incorrectly, if times out) – See Pumpdown.

5.

Compressor Not Operating

5. Check overloads and contactor.

6.

Check Suction Temperature Sensor

6. Compare board sensor reading against

actual suction line temperature.

7.

Check Suction Pressure Transducer

7. Compare pressure reading against gauges.