Checking operation of expansion valve, Checking operation of expansion valve (eev), Expansion valve motor winding resistance – Heatcraft Refrigeration Products BEACON II H-IM-79E User Manual

Page 19

19

Checking Operation Of Expansion

Valve (EEV)

To check if the expansion valve is closing properly:

Install a pressure gauge-set to suction line at

the condensing unit. With the system running,

close the valve on the liquid line, at the con

densing unit. The system should pumpdown

and shut off on the low pressure switch (LPS).

If the system does not pumpdown and trip on

the LPS then the compressor valves are weak

and needs to be changed.

After the system pumps-down and trip on the

LPS, put the system in the service mode. This

will cause the expansion valve to close. Open

the valve on the liquid line, at the condensing

unit. The suction pressure reading on the gauge

set should not increase. If the suction pressure

increases then the expansion valve is leaking

and should be changed.

Checking Operation of Expansion Valve

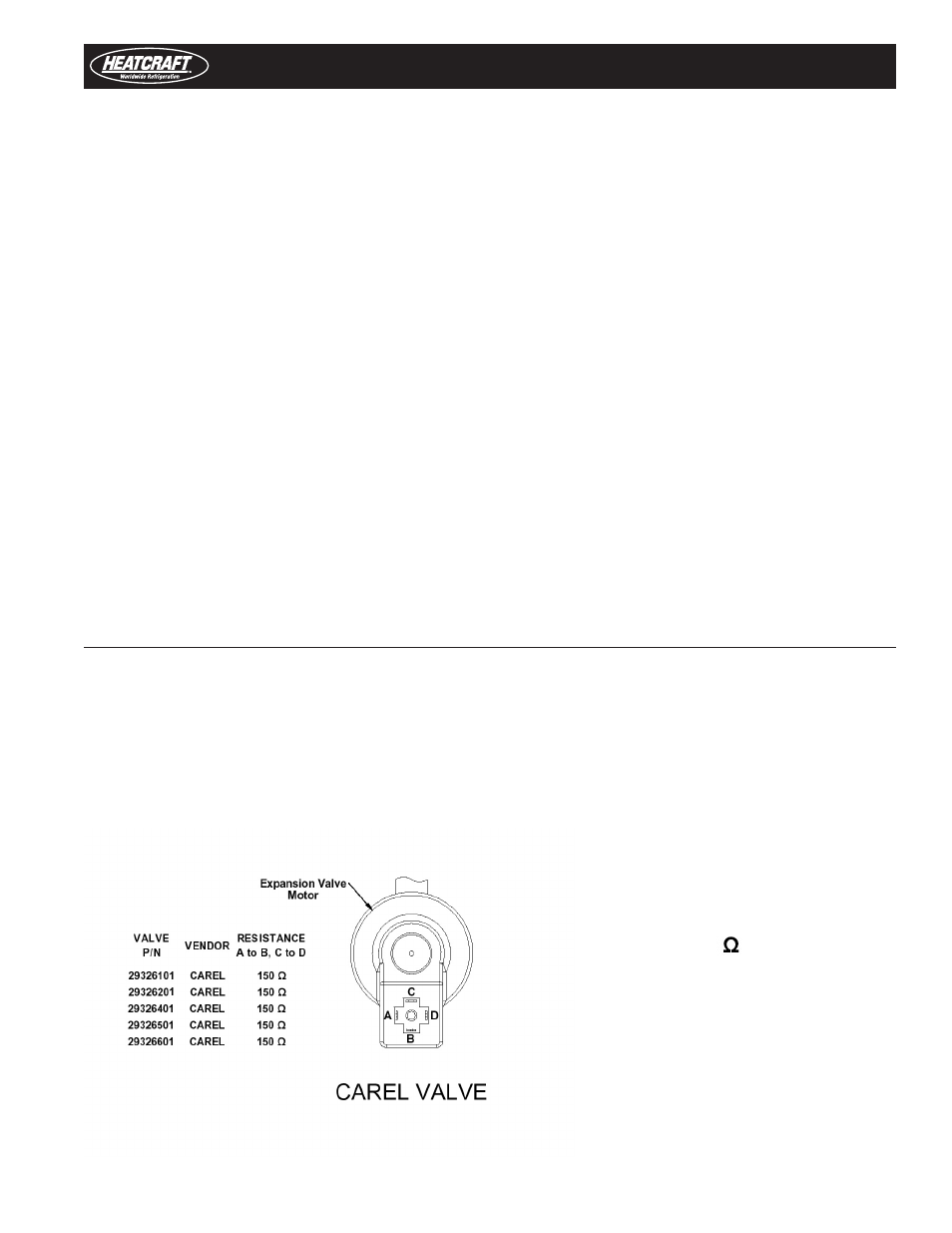

If the expansion valve is suspected of not functioning properly the motor windings resistance should be measured.

This is a bipolar motor with two windings. Measure the resistance at the pins, on top of the valve, between locations

A and B or C and D.

(Note that the pins are not labeled A, B, C, D. This labeling is just for reference).

The expansion valve position can be monitored from

the LED display pressing the “

MONITOR” button and

scrolling to

ESP. This will indicate the number of steps

the valve is open.

This can also be checked by using the EXV test pins on

the board. This is indicated by a 0 to 5 volts DC signal.

At 0 volt the valve is closed and at 5 volts the valve is

fully open. At values between 0 and 5 volt, the valve will

be opened proportionately.

Use the “

MONITOR” button to display “SCP””

Evaporator Suction Pressure. Record the pressure

displayed. Start the system and observe the pressure

displayed. If the pressure does not increase, the

expansion valve could be defective.

If the system is running, use the “

MONITOR” button to

display “

SCP” Evaporator Suction Pressure. Record the

pressure displayed. While the system is running, press

the “

FORCE SERVICE” button. Observe the pressure

while the system is pumping down. The pressure should

decrease. If it does not, this indicates a defective valve.

Expansion Valve Motor Winding Resistance

Continues to Page 20

Resistance reading at 150

at 75° F

“C” is largest spade