Figure 5-3. normal operation -3, Ee figure 5-3), Hazardous area oxymitter 4000 – Emerson Process Management OXYMITTER 4000 User Manual

Page 77: Instruction manual

Instruction Manual

IB-106-340C Rev. 4.1

July 2004

Rosemount Analytical Inc. A Division of Emerson Process Management

Startup and Operation with Keypad 5-3

Hazardous Area Oxymitter 4000

4. CAL LED. The CAL LED is on steady

or flashing during calibration. Further

information is available in Section 9,

MAINTENANCE AND SERVICE.

5. Keys.

(a) INC and DEC. The INC and DEC

keys are used to set the values of

the calibration gases. Attach a

multimeter across TP5 and TP6.

The calibration and process gases

can now be monitored. Pressing

the INC or DEC once will cause

the output to switch from the proc-

ess gas to the calibration gas.

Pressing INC or DEC a second

time will increase or decrease the

calibration gas parameter. If the

keys have been inactive for one

minute, the output reverts to the

process gas. When a calibration

has been initiated, the value at

TP5 and TP6 is the % O

2

seen by

the cell.

Oxygen levels, as seen on the

multimeter, are:

8.0% O

2

= 8.0 volts DC

0.4% O

2

= 0.4 volts DC

(b) CAL. The CAL key can:

1 Initiate a calibration.

2 Sequence through calibration.

3 Abort

the

calibration.

NOTE

Refer to Section 9, MAINTENANCE AND

SERVICE, for calibration instructions.

b. Model 751 Remote Powered Loop

LCD Display (Optional)

Refer to Remote Powered Loop LCD

manual for calibration and operation.

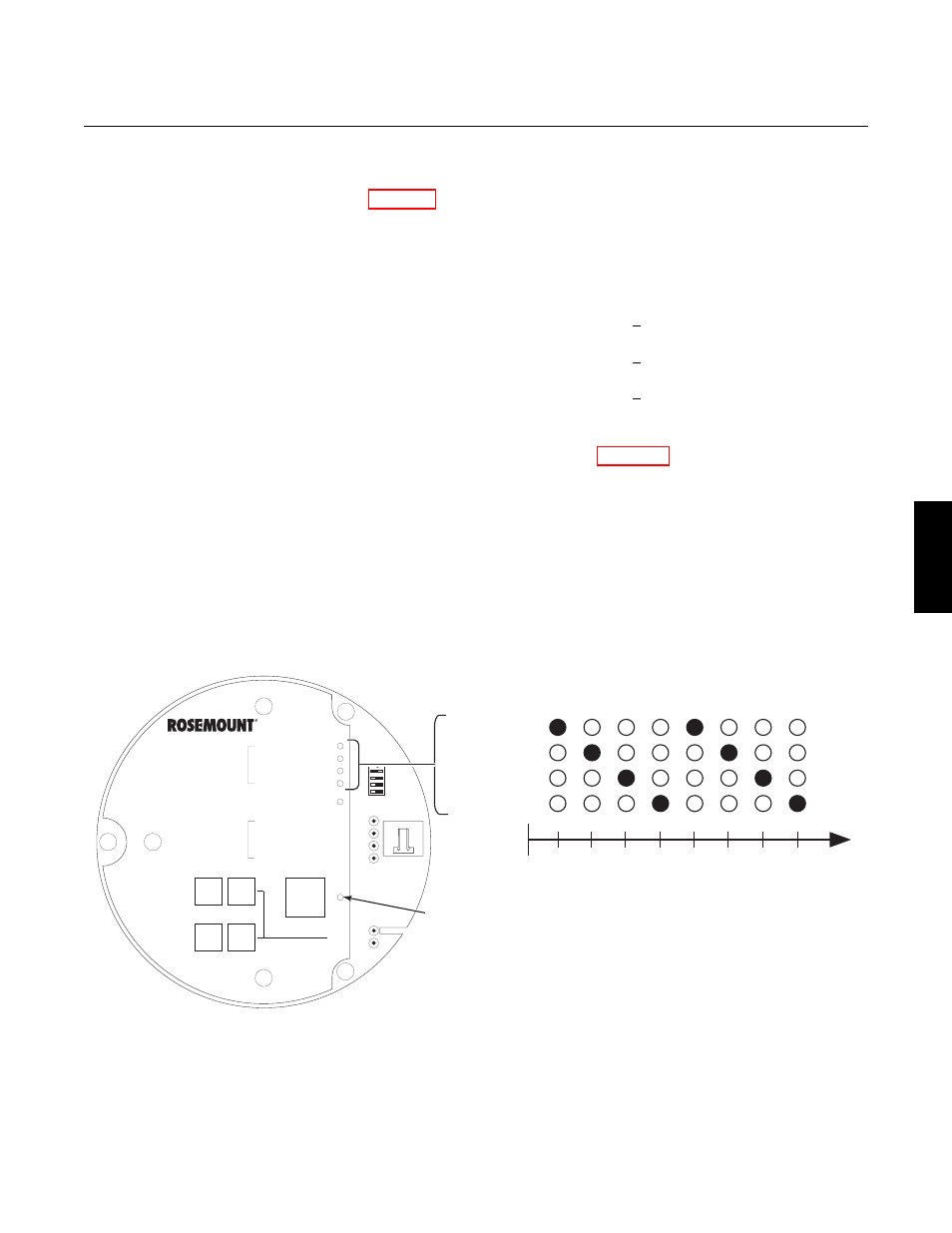

HEATER T/C

HEATER

O CELL

2

CALIBRATION

LIGHTING SEQUENCE DURING NORMAL OPERATION

1

2

3

4

1

2

3

4

DIAGNOSTIC

ALARMS

TEST

POINTS

HEATER T/C

HEATER

O2 CELL

CALIBRATION

CALIBRATION RECOMMENDED

O2 CELL mV +

O2 CELL mv -

HEATER T/C +

HEATER T/C -

INC

INC

DEC

DEC

HIGH

GAS

LOW

GAS

CAL

TEST GAS +

PROCESS -

% O2

SW2

TP1

J1

TP2

TP3

RED

YEL

GRN

ORG

TP4

TP5

TP6

ON

CAL LED

22220055

Figure 5-3. Normal Operation

5