Figure 9-5. electronic assembly -10, Hazardous area oxymitter 4000, Instruction manual – Emerson Process Management OXYMITTER 4000 User Manual

Page 128

Instruction Manual

IB-106-340C Rev. 4.1

July 2004

9-10 Maintenance and Service

Rosemount Analytical Inc. A Division of Emerson Process Management

Hazardous Area Oxymitter 4000

(f) Restore power to the system; refer

to paragraph 5-1 or 6-1. When the

probe is at operating temperature,

calibrate the probe per paragraph

9-2.

NOTE

Recalibration is required whenever

electronic cards or sensing cell is

replaced.

b. Replacement of Entire Electronics

(with Housing) – Hazardous Area

Oxymitter 4000 with Integral Electronics.

1. Follow the instructions in paragraph

9-4a to remove the Hazardous Area

Oxymitter 4000 probe from the stack

or duct.

Do not force the probe housing when

installing or removing from the inte-

gral electrical barrier/feedthrough

(Figure 9-3). Damage to the aluminum

probe housing can occur.

2. Remove four screws (22, Figure 9-3)

and washers (21) from the probe tube

assembly (23). Remove the probe tube

assembly from the housing (11).

3. Disconnect the heater and signal wire

connectors from the mating connectors

on the heater strut assembly (32).

NOTE

The integral electrical barrier/feed-

through is thread-locked into the elec-

trical housing and cannot be

removed.

4. Make sure the O-ring (31) is in good

condition. Replace O-ring if damaged.

5. Make sure that the conduit port of the

electronic housing is on the same side

as the CAL and REF gas ports. Install

four washers (21) and screws (22).

Tighten screws.

6. Follow the instructions in paragraph

2-1b to install the Hazardous Area

Oxymitter 4000 into the stack or duct.

Opening the electronic housing will

cause the loss of ALL hazardous per-

mits. Opening the electronics housing

in hazardous areas may cause an

explosion resulting in loss of property,

severe personal injury, or death. It

may be required to get a hot work

permit from your company safety offi-

cer before opening the electronic

housing.

c. Electronic

Assembly

Replacement

Remove and replace the electronic assem-

bly according to the following procedure.

1. Remove screw (18, Figure 9-3 or

Figure 9-4), cover lock (19), and cap-

tive washer (20) securing cover (1).

Remove the cover.

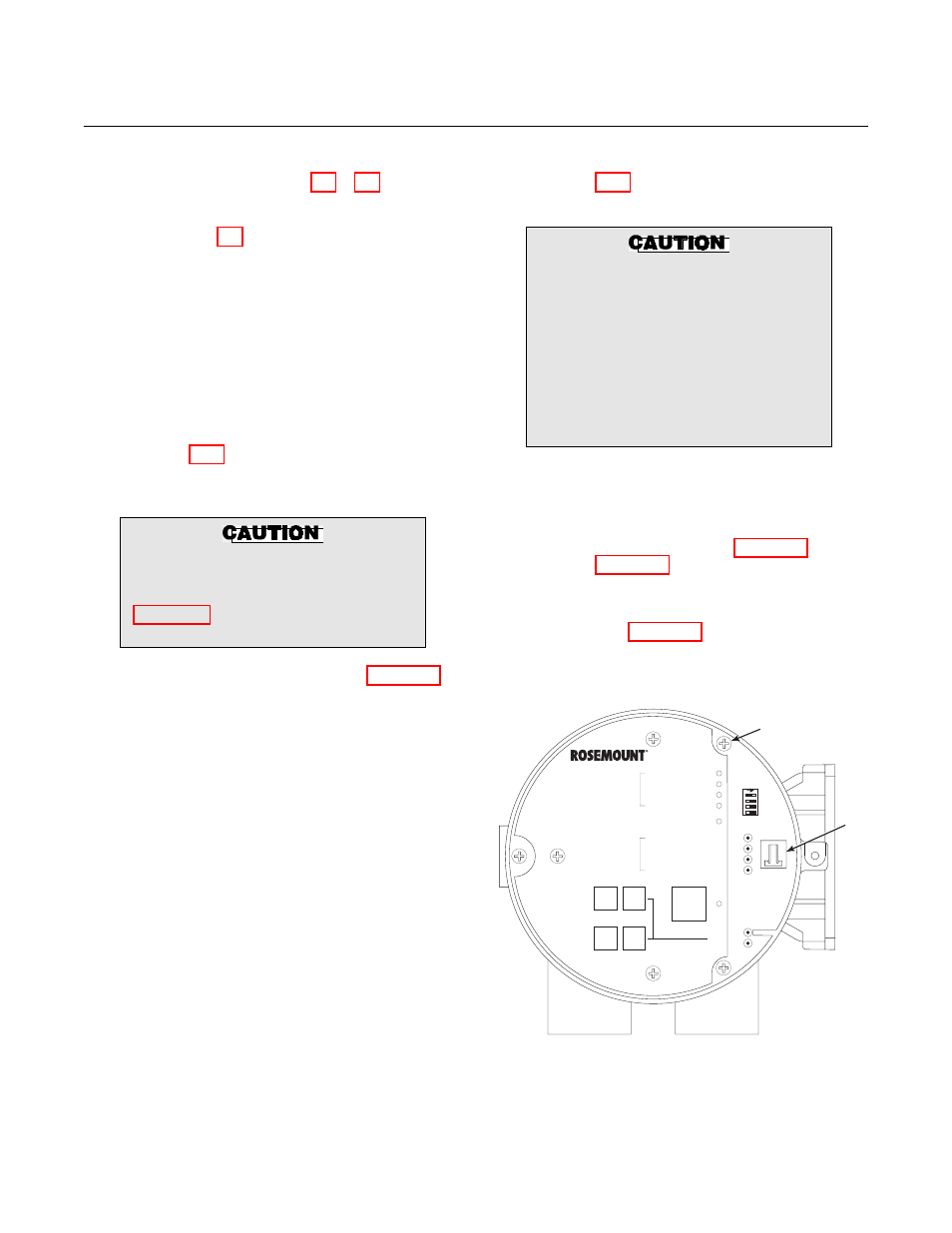

2. See Figure 9-5. Depress and remove

the J1 (cell and T/C) connector from

the J1 socket.

DIAGNOSTIC

ALARMS

TEST

POINTS

HEATER T/C

HEATER

O2 CELL

CALIBRATION

CALIBRATION RECOMMENDED

O2 CELL mV +

O2 CELL mv -

HEATER T/C +

HEATER T/C -

INC

INC

DEC

DEC

HIGH

GAS

LOW

GAS

CAL

TEST GAS +

PROCESS -

% O2

SW2

TP1

J1

TP2

TP3

RED

YEL

GRN

ORG

TP4

TP5

TP6

ON

J1

MOUNTING

SCREW

37270018

Figure 9-5. Electronic Assembly