Figure 8-5. fault 3, reversed thermocouple -7, Hazardous area oxymitter 4000, Alarms o2 t/c reversed – Emerson Process Management OXYMITTER 4000 User Manual

Page 103: Instruction manual

Instruction Manual

IB-106-340C Rev. 4.1

July 2004

Rosemount Analytical Inc. A Division of Emerson Process Management

Troubleshooting 8-7

Hazardous Area Oxymitter 4000

DIAGNOSTIC

ALARMS

TEST

POINTS

HEATER T/C

HEATER

O2 CELL

CALIBRATION

CALIBRATION RECOMMENDED

O2 CELL mV +

O2 CELL mv -

HEATER T/C +

HEATER T/C -

INC

INC

DEC

DEC

HIGH

GAS

LOW

GAS

CAL

TEST GAS +

PROCESS -

% O2

SW2

TP1

J1

TP2

TP3

RED

YEL

GRN

ORG

TP4

TP5

TP6

ON

37260021

Alarms

O2 T/C Reversed

LOI

KEYPAD

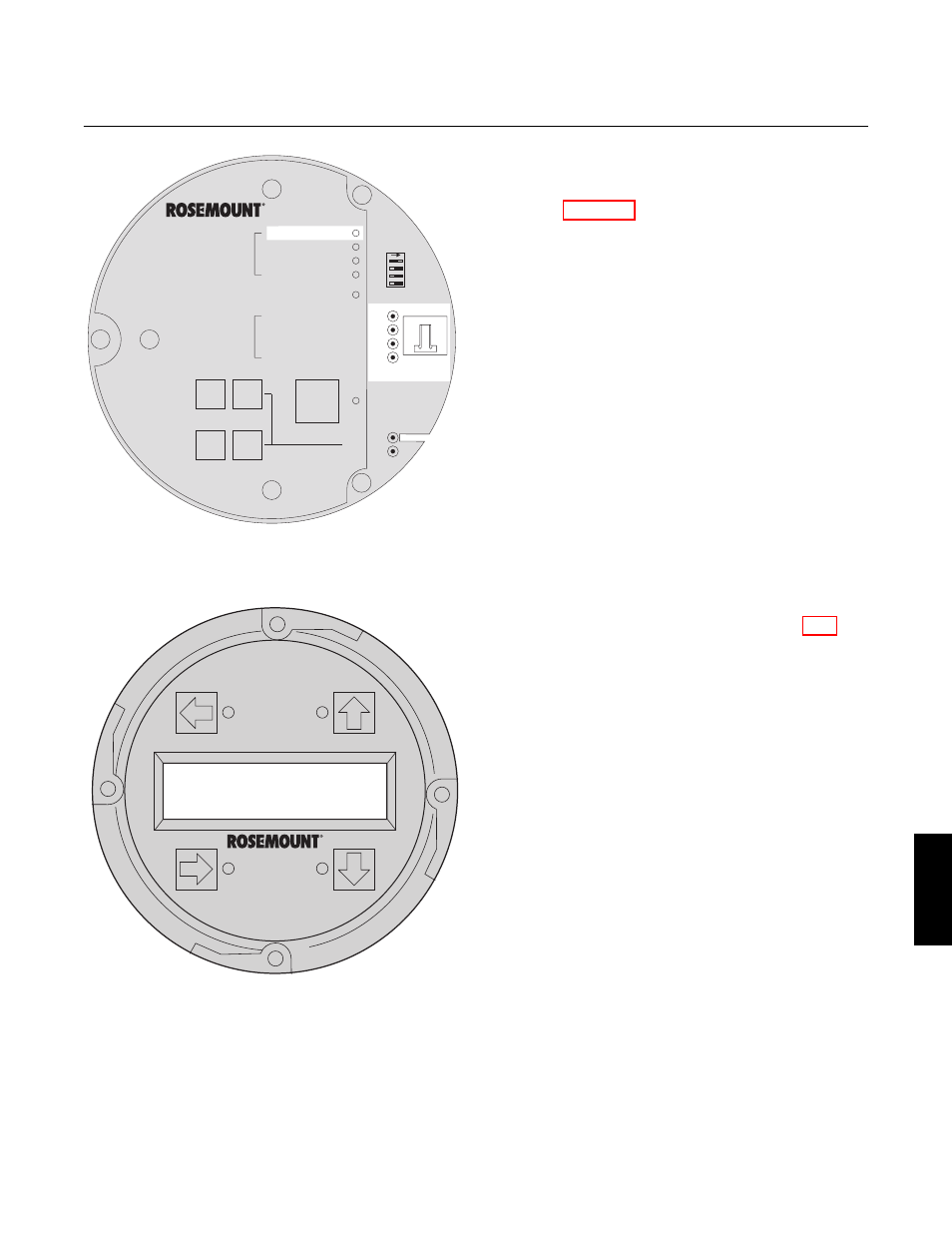

Figure 8-5. Fault 3, Reversed Thermocouple

c. Fault 3, Reversed Thermocouple Wiring

or Faulty PC Board

Figure 8-5 shows the electronic assembly

for a Hazardous Area Oxymitter 4000 with

a membrane keypad (upper view) and a

Hazardous Area Oxymitter 4000 with an

LOI (lower view). The upper view also

shows J1 and test points TP1 through TP6,

located on the microprocessor board, below

the membrane keypad or the LOI module.

Membrane Keypad. When Fault 3 is

detected, the HEATER T/C LED flashes

three times, pauses for three seconds, and

repeats.

1. Using a multimeter, measure the volt-

age from TP3+ to TP4-. If the reading

is negative, the thermocouple wiring is

reversed.

2. Check red and yellow wires in the J1

connector for the proper placement.

3. If the wiring is correct, the fault is in

the PC board. See paragraph 9-4c,

Electronic Assembly Replacement.

LOI. When Fault 3 is detected, the LOI

displays the “O2 T/C Reversed” message.

1. Remove power. Unscrew and remove

the LOI module from the electronic

assembly.

2. Reconnect power to the Oxymitter

4000.

3. Perform the diagnostic steps 1 through

3 shown for the membrane keypad.

8