Woodhaven 7280: Bandsaw Fence User Manual

Page 2

1

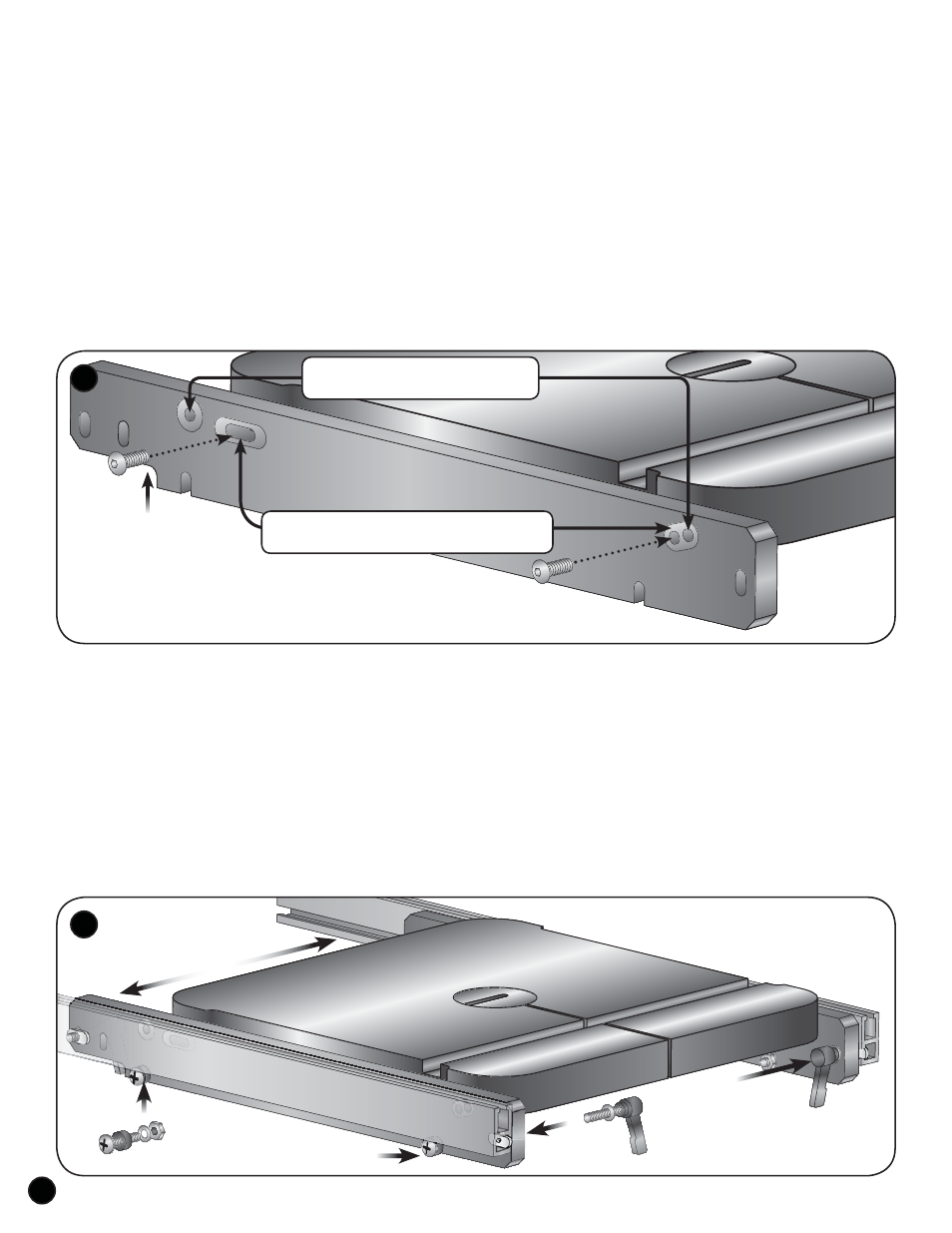

ATTACH TRACKS TO BRACKETS

Install a washer (WB002) on the stud of the four Ratchet Handles

(5859, 7/8" stud). Each Bracket has three slots. One slot is located

near the outboard end of the Bracket and two slots are located near the

inboard end of the Bracket. Use the slot located near the outboard end

of the Bracket and the most accessible slot of the two at the inboard end

of the Bracket. From the inside face of each Bracket, insert the stud thru

the slot and start an oval nut (5760B - smooth side first, 4 total) on the

end of each stud. See fig. 2

Slide a 24" Double Track (4024) on each pair of oval nuts until

it’s protruding past the outboard end of the Bracket about 1/8". Adjust

the Double Track so the top of it is 7/16" below the band saw table and

tighten the Ratchet Handles. See fig. 2

Install a 1/4" spacer (BUSH525), washer (WB002) and nut

(NUT015) on the four 1" screws (5772B). Slide the screw in the open

slots in the bottom of both the front and rear Brackets. The Bracket

should be sandwiched between the screw head/spacer in the front and

the washer/nut in the back. Position them so the spacer is against the

underside of the Double Track and tighten. The spacers maintain the

track height when the Ratchet Handles are loosened, allowing you to

shift the track left or right as desired. See fig. 2.

BEFORE BEGINNING

Read the instructions at least once, familiarizing yourself with

the parts before beginning. Tools needed for assembly: 7/16" wrench

and a #3 Phillips screwdriver. This Fence was designed for use with a

14" Delta, Porter Cable, Jet or clones. The band saw table must have

tapped holes in the table edge.

The Band Saw Fence may be able to be adapted to fit other band

saws by drilling four holes in the front and rear Brackets (7280D) to

match the mounting holes in your band saw, and/or in the band saw

table edge. Make sure there are no ribs under the table to interfere. The

table edges must be square to the table top and parallel to each other.

ATTACH BRACKETS TO TABLE

Get the pair of Brackets (7280D). One Bracket mounts on the

front and one mounts on the back, with the front Bracket identified by a

notched end. See fig. 1

Determine which screw size (inch or metric) your table is threaded for

by testing its tapped hole with the 1/4-28 x 1" screws (MB008, most

Deltas), the M6 x 25mm screws (MB007, most Jets and clones) or the

M6 x 20mm screws (MB006, Porter Cable).

For most Deltas, Jet and their clones, attach the Brackets using the

hole and slot indicated, to the table edge using a washer (WB002) on

each screw (MB007 or MB008).

For a Porter Cable PCB330BS Band Saw, attach the Brackets,

using the two holes indicated, to the table edge using a washer (WB002)

on each screw (MB006).

Tighten the screws with the allen wrench (5785). Ideally the top

edge of the Brackets will be slightly below the miter slot so they don't

interfere with a miter gauge, however if the Bracket is slightly above it,

you can notch the Brackets to allow use of a miter gauge. See fig. 1

1

2

Ratchet Handles mounted

in outboard slots

Ratchet Handles mounted

in inboard slots

Ratchet Handle, Washer & Oval Nut: x4

Mount in inboard & outboard slots of Brackets

Screw, Spacer, Washer, & Nut: x4

Mount in bottom Bracket slots

7280D Brackets:

Front Bracket (shown)

notched on left side, back

Bracket not notched.

Use the outer two holes with MB006 for a

Porter Cable PCB330BS band saw.

Use the interior hole & slot with

MB007 or MB008 for a Delta, Jet or clone band saw.