Woodhaven 5434: Frame and Panel Master User Manual

Page 4

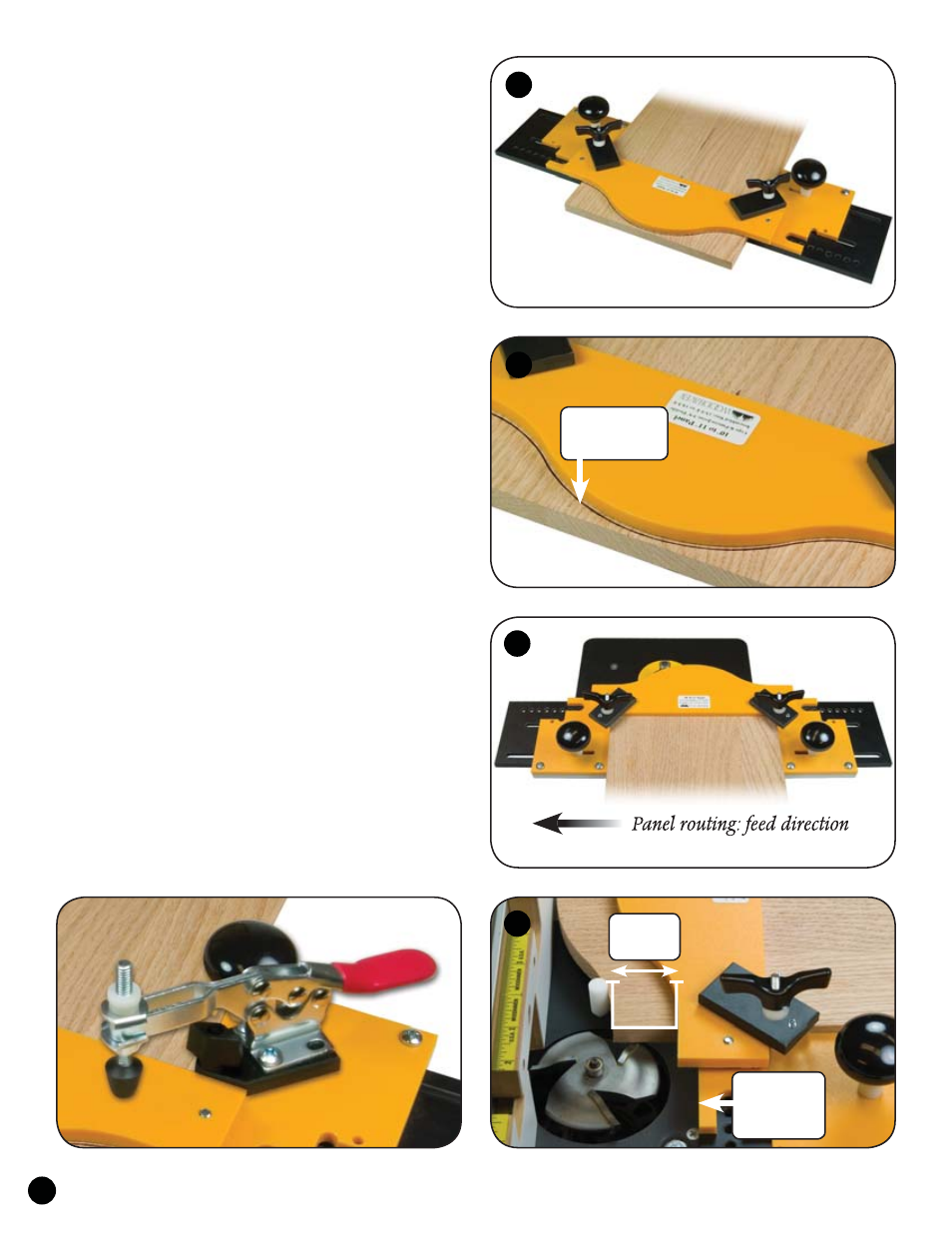

MARK & CUT PANEL PROFILE

Place the panel on the base and slide the fences up against

each side of the panel so it's between the straight edges of the

fences. Place the template on the 1-1/4" bolts. See fig. 3 & 10.

Adjust the fences to center the panel on the template so

there is an even amount of template overhanging the panel at

each end. Using the template as a pattern, draw a pencil line on

the panel. See fig. 11. Remove the panel and rough saw it to

shape, staying approximately 1/8" away from the finished line.

Re-install the template and panel on the base. Clamp the

template/panel to the base using the knobs on top of the clamp

pads. The knobs are larger than previous ones so they're

easier to tighten. However overtightening may cause damage

to the jig! Hold the jig by the handles and machine the panel to

shape using a flush trimming bit. See fig. 12.

Remove the machined panel and install another. You can

also use the Frame & Panel Master to hold the panel as you

machine the raised panel profile in the curved edge. This will

work only if you install the panel so it projects past the template

at least 1-5/8" to prevent the bit from cutting into the base. See

fig. 13.

For best results, and optimum control, use a fence for sup-

port. Adjust the fence position so that the highest part of the

panel is touching the fence. This lets you slide along the fence,

until the part has reached the bit. See fig. 13.

ACCESSORIES

The optional Clamps take the place of the standard 5560

knobs for faster part clamping.

©Copyright WOODHAVEN INC. 7/16/07

(800) 344-6657 or WWW.WOODHAVEN.COM

Panel routing: feed direction

12

Do not

allow bit to

strike base!

At Least

1-5/8"

13

Draw line for

rough cut

11

10

3