Woodhaven 5434: Frame and Panel Master User Manual

Page 3

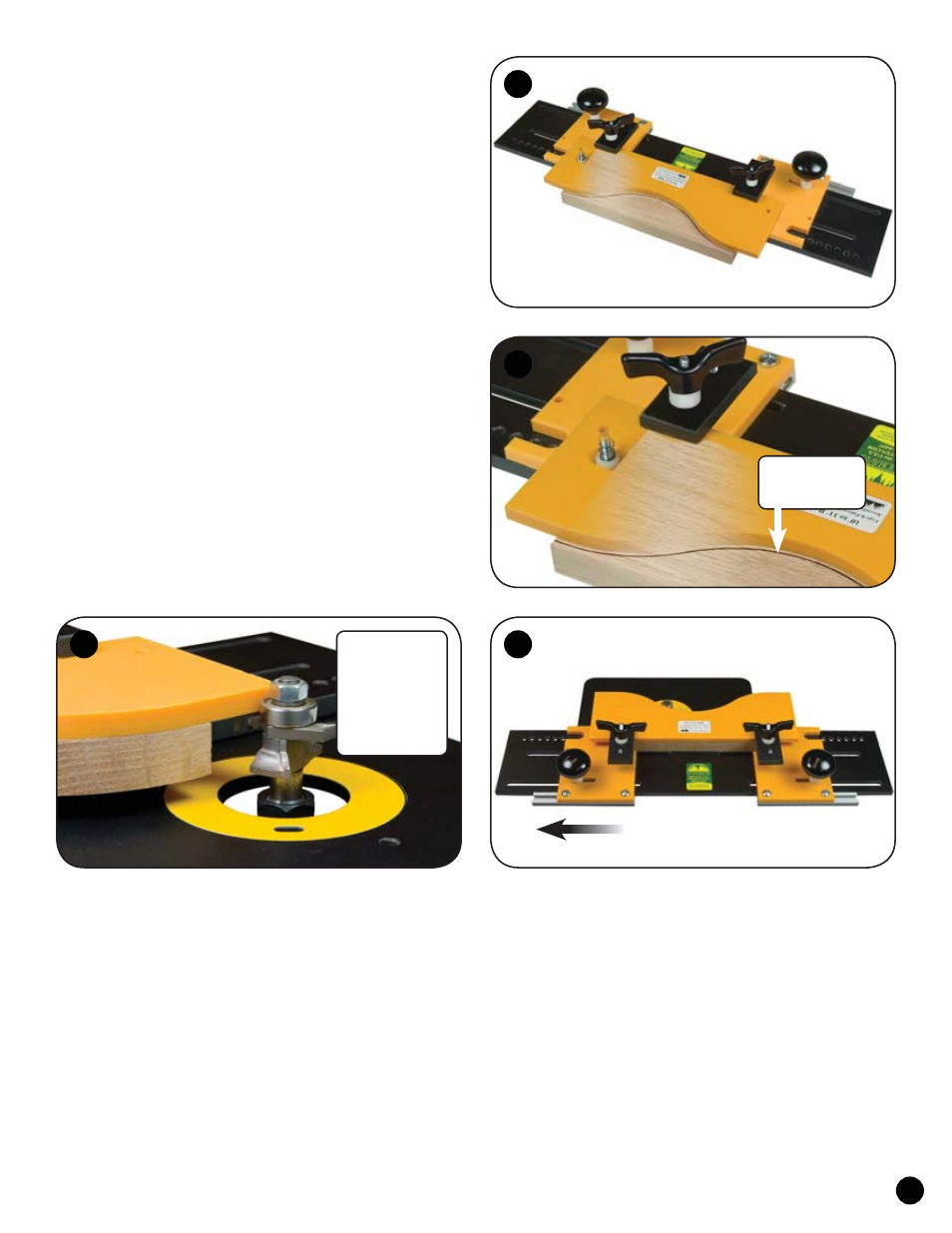

MARK & CUT RAIL PROFILE

Place the rail on the base and slide the fences up against

each end of the rail so it's between the notches in the fences.

Place the template on the 1-1/4" bolts. See fig. 2 & 6.

Adjust the fences/rail to center the rail on the template

so there is an even amount of template overhanging the rail at

each end. Using the template as a pattern, draw a pencil line on

the rail. See fig. 7. Remove the rail and saw it to shape, staying

approximately 1/8" away from the finished line.

Re-install the rail and template on the base. Clamp the

template/rail to the base using the knobs on top of the clamp

pads. The knobs are larger than previous ones so they're

easier to tighten. However overtightening may cause damage

to the jig! Hold the jig by the handles and machine the rail to

shape using a flush trimming bit. See fig. 8.

Remove the machined rail and install another. If you have

a second router setup, you can go directly from shaping the rail

with a flush trim bit to machining the pattern (up to 1/2" deep)

without having to remove the rail between operations. For

the safest pattern cutting operation, at least 1/8" of the bearing

should ride on the template at the start of the cut. This way the

template acts as a starting pin, providing the best control of the

part. Depending on part thickness, this may require you to add

a spacer between the bearing and the cutter. See fig. 9.

Rail routing: feed direction

Draw line for

rough cut

Place template on

1-1/4" bolts

Place rail between &

against notches in fences

2

8

7

6

9

For safety,

at least 1/8"

of bearing

should ride

on template