Vortech 2011-2012 6.4L Hemi Challenger User Manual

Page 13

P/N: 4CL020-020 v1.0, 12/02/2014

©2014 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

3

3.

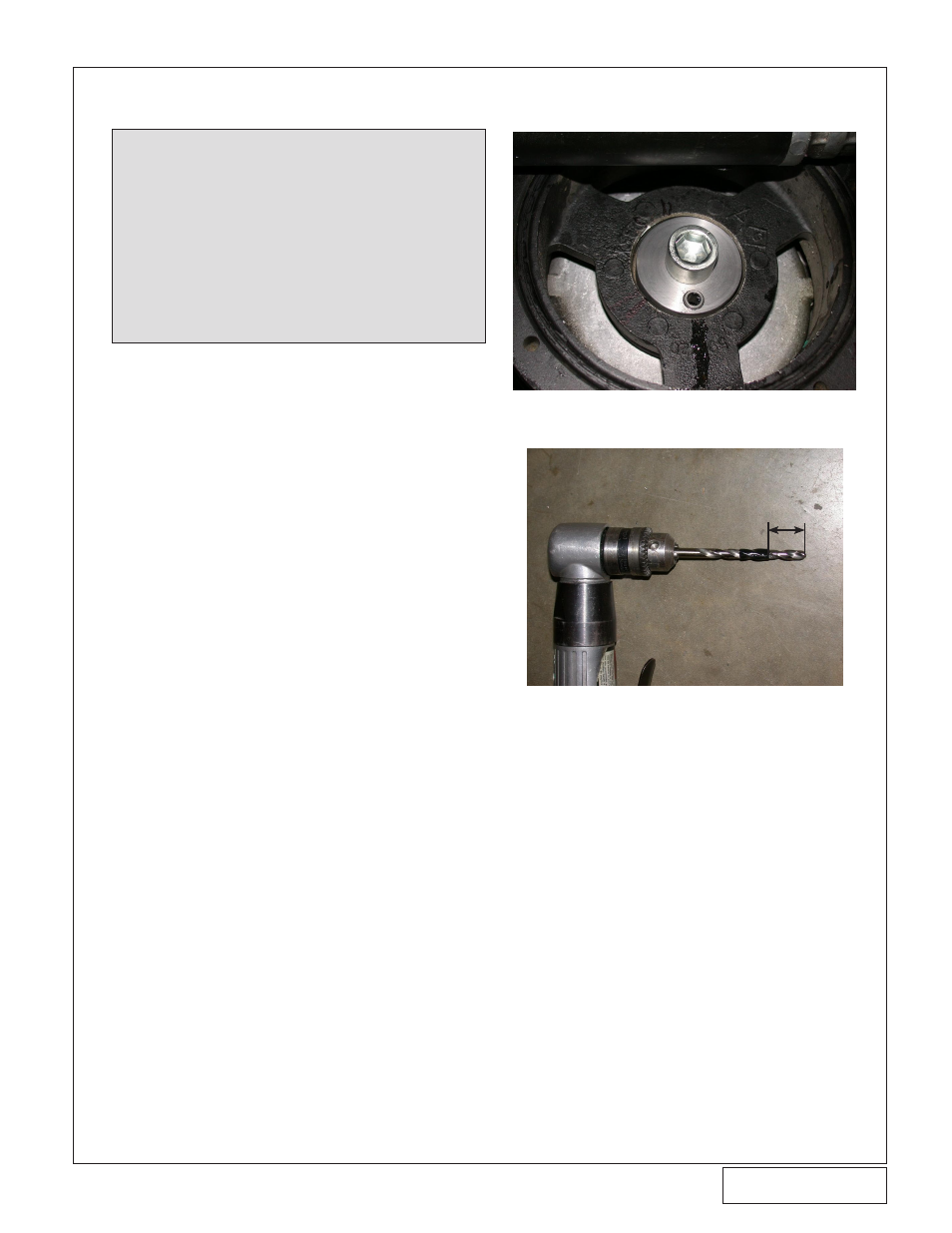

HaRMONIC DaMPER DOWEL PIN INSTaLLaTION

A. Remove the crankshaft damper bolt. (A fac-

tory tool may be used to keep the engine from

rotating or carefully use a pry tool to keep the

damper from rotating.)

B. Install the supplied drill guide with the raised

section piloting in the damper bore. Secure

in place by installing the supplied socket head

cap screw. Do not over-tighten the screw as it

may distort the drill guide (its purpose is just to

hold the guide in place while drilling). See Fig.

3-a.

C. Using a small drill motor (right angle pneumatic

works well), mark a 1/4” drill bit with electrical

tape or a drill stop so that the hole will be deep

enough for the supplied 1/2” long dowel pin.

See Fig. 3-b.

D. Drill hole in damper/crankshaft.

E. Remove the socket head cap screw.

F. Clean area of metal chips and install the supplied

dowel pin in the drilled hole making sure that it

does not protrude past the damper face.

G. Install and tighten the crankshaft damper bolt

to 129 ft-lbs (176 Nm).

H. Re-install the radiator fans and verify that the

electrical connector is plugged in.

Fig. 3-a (Supplied Drill Guide Tool)

Fig. 3-b

NOTE: The purpose of this section is to provide ac-

cess to the harmonic damper bolt area so that

the crankshaft can be pinned to the damper

to prevent the damper from spinning on the

crankshaft. The following steps will work on

all or most applications. If it is not possible

to get adequate clearance by performing the

following steps, follow the manufacturer’s

steps for removing the harmonic damper until

there is sufficient room to work in.

1” MINIMUM