SOR TA Nuclear Qualified Pressure Switch User Manual

Page 2

2/4

Form 654 (04.13) ©SOR Inc.

To check the set point of a switch, monitor either the common (C) and normally open (NO)

or the common (C) and normally closed (NC) contacts for change of state. Connect the

process connection to a regulated hydraulic or pneumatic pressure source. Monitor with

an accurate pressure measuring standard. Slowly increase or decrease the pressure to

accurately capture the precise moment that the switch changes state. To assure the most

accurate and repeatable results, the switch must be tested in an identical manner each time

the calibration is checked.

Store switch in a dry area in the original shipping package. Shelf life is 10 years for a maxi-

mum ambient temperature of 80°F, based on aging data in SOR Test Report 9058-102.

Site Storage

Calibration

Minimum Bend Radius for Wire

Permanent Training

1/2”R

Pulling Tension

1”R

Terminating Junction

1/4”R

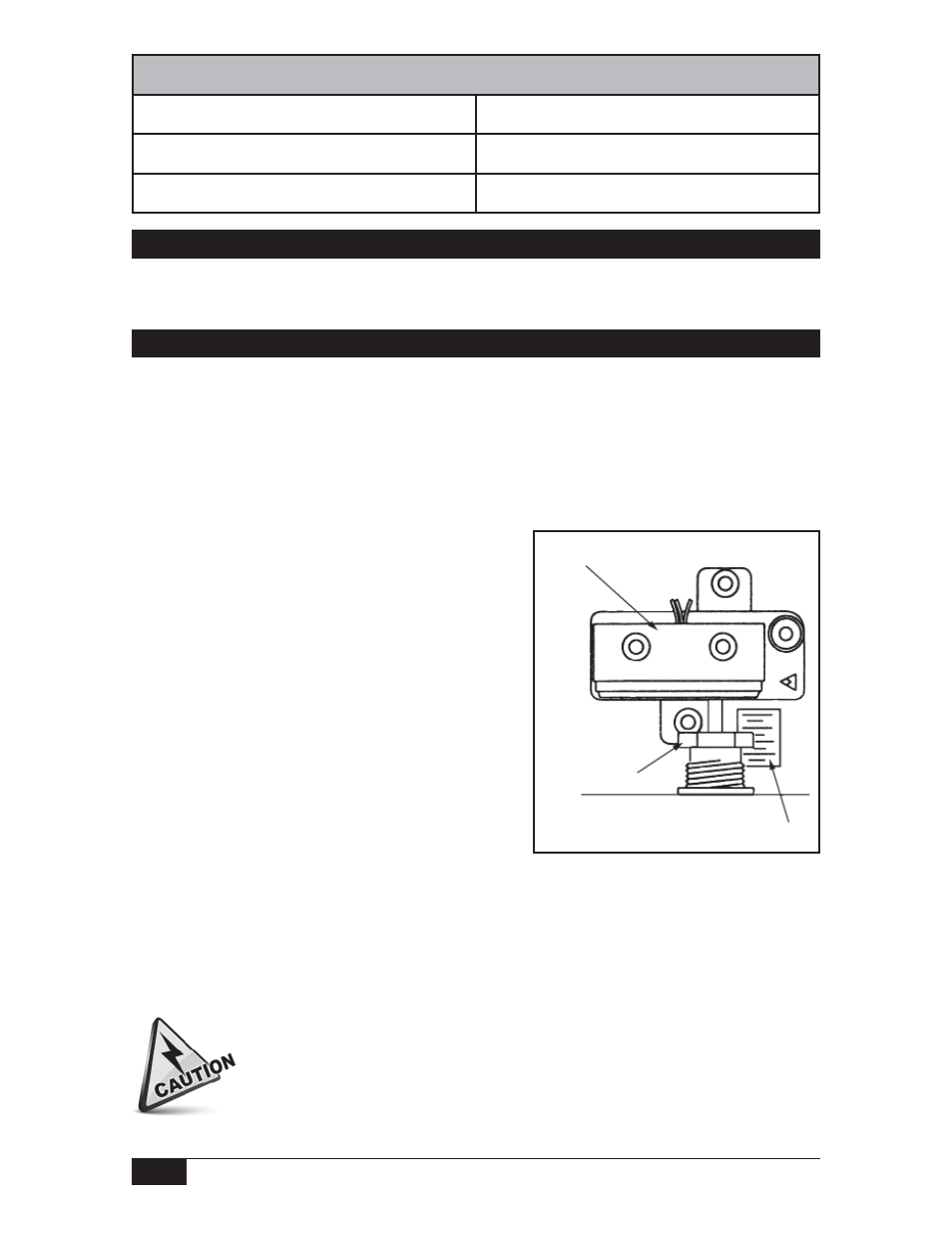

Switching Element

Calibration Scale

Adjusting Nut

The switching element has been positioned with a dial indicator to a tolerance

of ±.002 inches. Do not move this switching element! Its position has nothing

to do with the set point adjustment. Any movement can either render the switch

inoperative or cause the switching element to be damaged with overpressure.

Increasing Set Points

If the normal operating pressure is below the set point,

then the pressure should be increased from 0 PSI up to

the increasing set point and then back down to the

reset point. Repeat this cycle as necessary.

Decreasing Set Points

If the normal operating pressure is above the set point,

then the calibration should be checked by first pressur-

izing to the normal operating pressure, then reducing the

pressure to the decreasing set point, and then increas-

ing the pressure to the reset point. Repeat this cycle as

necessary.

To adjust pressure at which switch will operate, remove cover and tighten the hex head adjusting nut

with a 3/4” wrench to increase pressure; loosen to reduce pressure. Sighting across the top of the

3/4-inch hex adjusting nut to the scale gives approximate set point pressure.

After calibration is complete, reinstall the cover with new gaskets or o-rings as required by

the Maintenance instructions.