Float-operated level switches - vertical – SOR Vertical Displacer Top Mounted Series Level Switch User Manual

Page 2

2/16

Form 425 (08.12) ©2012 SOR Inc.

Float-Operated Level Switches - Vertical

Operation

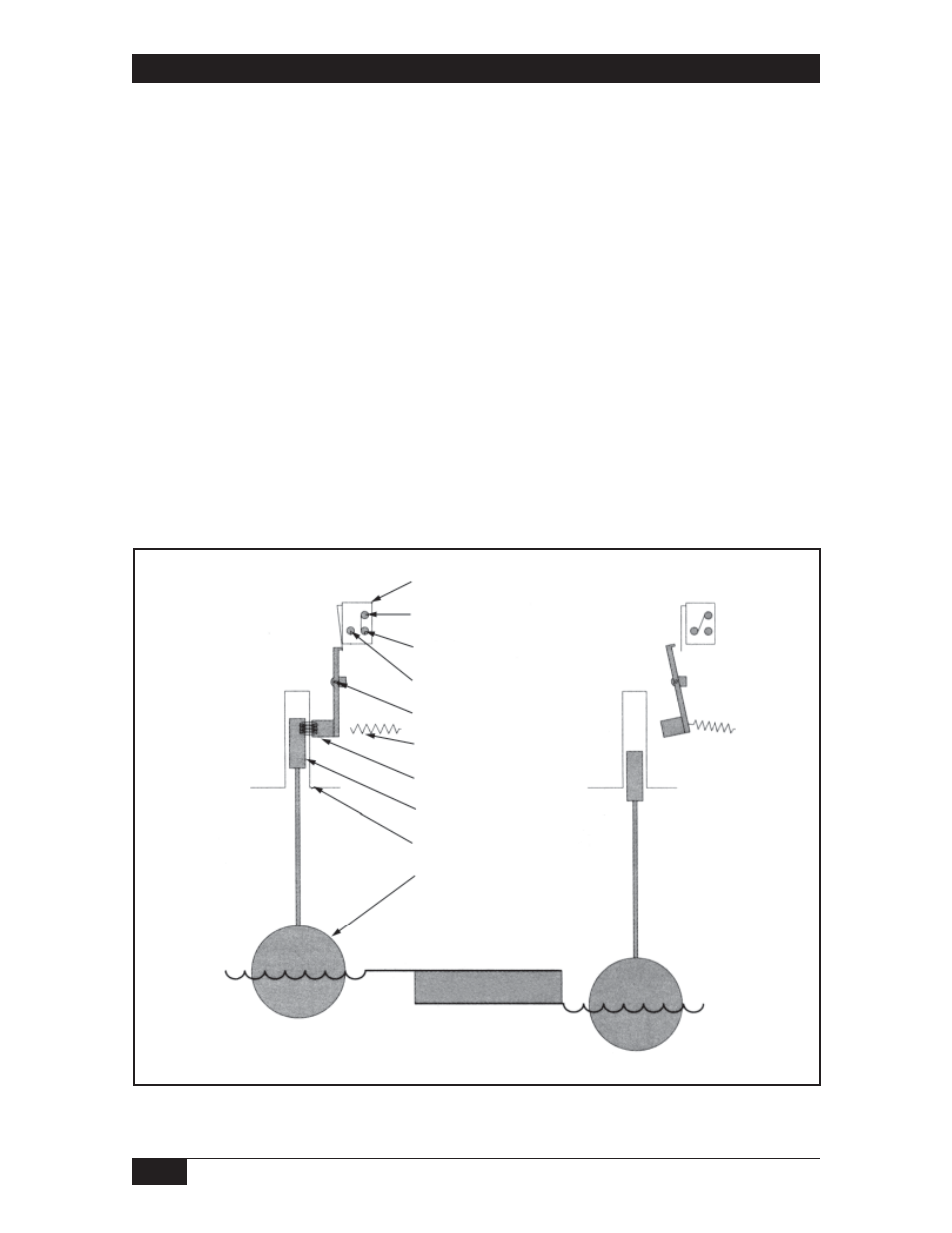

The float rides on the process liquid surface, precisely tracking liquid surface motion.

Floats are attached to a mechanical linkage. When rising liquid level meets the float,

buoyancy lifts the linkage and positions the attraction sleeve up in the enclosing

tube. Upward movement of the attraction sleeve positions it within the magnetic field

generated by the external magnet.

Magnetism pulls the external magnet in toward the attraction sleeve, and the external

magnet is tightly engaged against the enclosing tube actuating the switching element.

When liquid level falls, the attraction sleeve drops out of the magnetic field allowing the

float to pull the magnet away from the enclosing tube, deactuating the switch.

Switching Element

Common

Normally Open

Normally Closed

Pivot

Bias Spring

Magnet

Attraction Sleeve

Enclosing Tube

Float

Level Differential

Actuated

Deactuated

Float-Operated Level Switches - Vertical

NOTE: Float-type level switches are generally able to be used in high-temperature

applications, and sometimes prove useful for close interface detection.

NOTE: Floats are able to operate up to three switching elements. Independent switching

levels can be obtained with tandem fl oats. Consult the factory for special fl oat switching

arrangements.