SOR Opposed Piston User Manual

Page 3

Form 279 (02.13) ©SOR Inc.

3/12

Calibration

Process Connection

Pressure ports are marked Hi and Lo to indicate the high and low process pressure connec-

tions. Connect process piping accordingly. Use two wrenches-one to hold the hex pressure

port to prevent it from moving, the other to tighten the process pipe or tube fitting.

Care should be taken not to loosen the pressure port from the body or the

body from the housing.

Ensure that wiring conforms to all applicable local and national electrical codes and install

unit(s) according to relevant national and local safety codes.

SOR Opposed Piston Differential Pressure Switches in RB and RH housings have terminal

blocks as standard. All other Opposed Piston Differential Pressure Switches have 18-inch

18 AWG color-coded wire leads. Storing excess wire or making wire lead splices inside the

switch housing will interfere with switch operation.

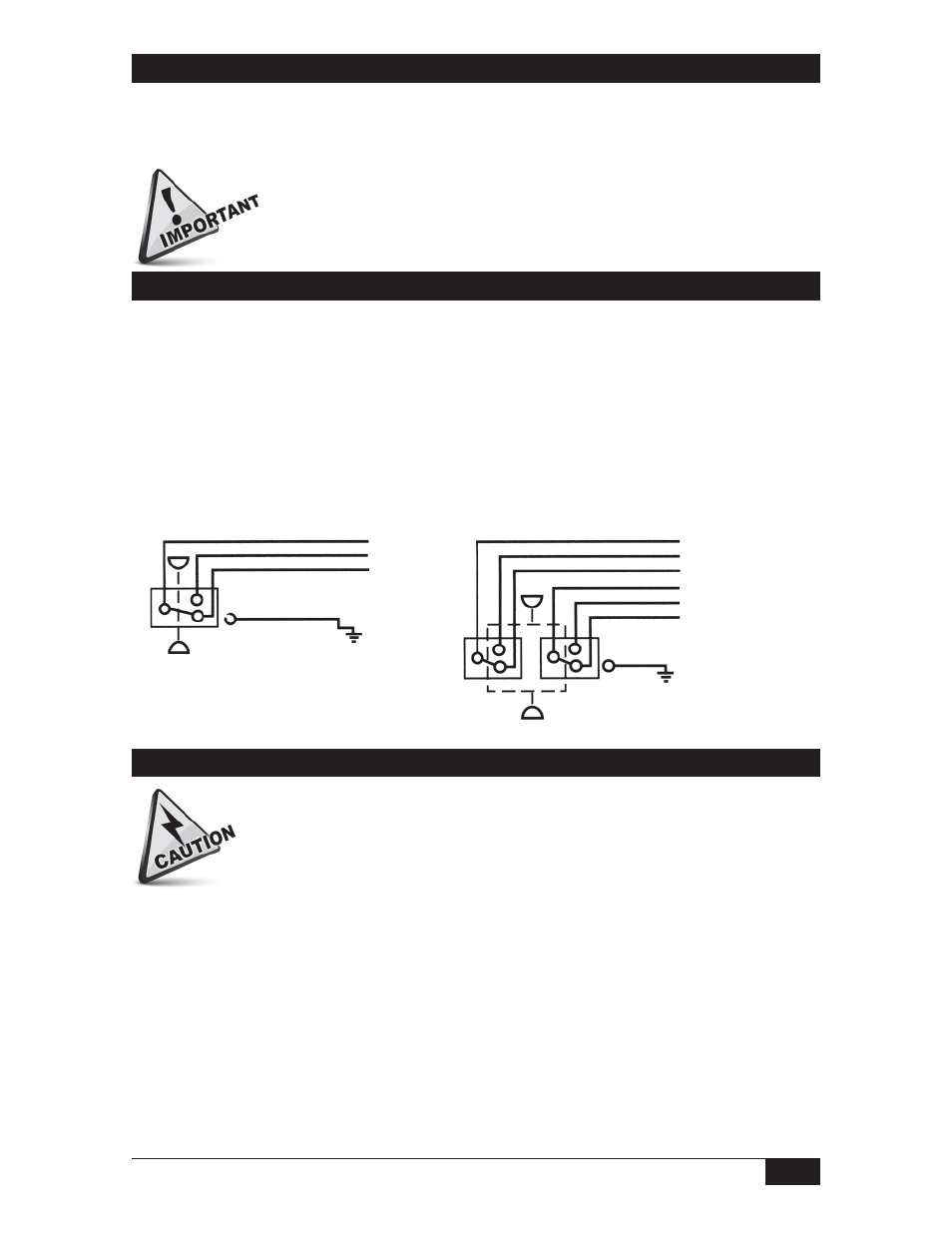

Electrical Connection

2-SPDT

Blue (C)

Black (NO)

Red (NC)

Yellow (C2)

Brown (NO2)

Orange (NC2)

Green (GND)

Differential Pressure

No.2

Hi

No.1

Lo

SPDT

Blue (C)

Black (NO)

Red (NC)

Green (GND)

Differential Pressure

Hi

Lo

Units in Hazardous Locations – Prior to calibration, make sure that the work

area is declassifi ed before removing the explosion proof cover to calibrate

the unit. Failure to do so could result in severe personal injury or substantial

property damage.

Remove housing cover. First, calibrate the device as a gauge pressure switch, i.e. Lo

side vented to atmosphere. Turn the set point adjusting nut located on the Hi side piston

clockwise to increase the set point, or counterclockwise to decrease the set point.

Calibrate to simulated system operating pressure conditions for optimum performance,

i.e.: connect Hi and Lo sides to suitable pressure sources and raise pressures

simultaneously to expected system operating pressure at desired set point. Vary Lo

side pressure and fine tune the set point adjustment for actuation (deactuation) of the

electrical switching element on increasing or decreasing differential pressure at

simulated system operating pressure.

Replace the cover.