3 maintenance schedule, 8 maintenance and service – Martin Christ Epsilon 2-10D LSCplus User Manual

Page 100

Freeze-dryer EPSILON 2-10D LSCplus

8 Maintenance and service

100

Version 04/2013, Rev. 1.5 of 16/12/2014 • sb

Translation of the original operating manual

Pos: 224 /20 0 Ch rist/3 61 G T-BA L abo r-Pilot (PROJEKTE)/Epsilo n Sta nda rd/0 80 Wa rtu ng u nd I nstan dhal tung /08 0-0 021 Wart ung splan Epsilon 6er 10 er @ 25\ mod _14 049 846 8138 5_6 8.d ocx @ 1859 31 @ 2 @ 1

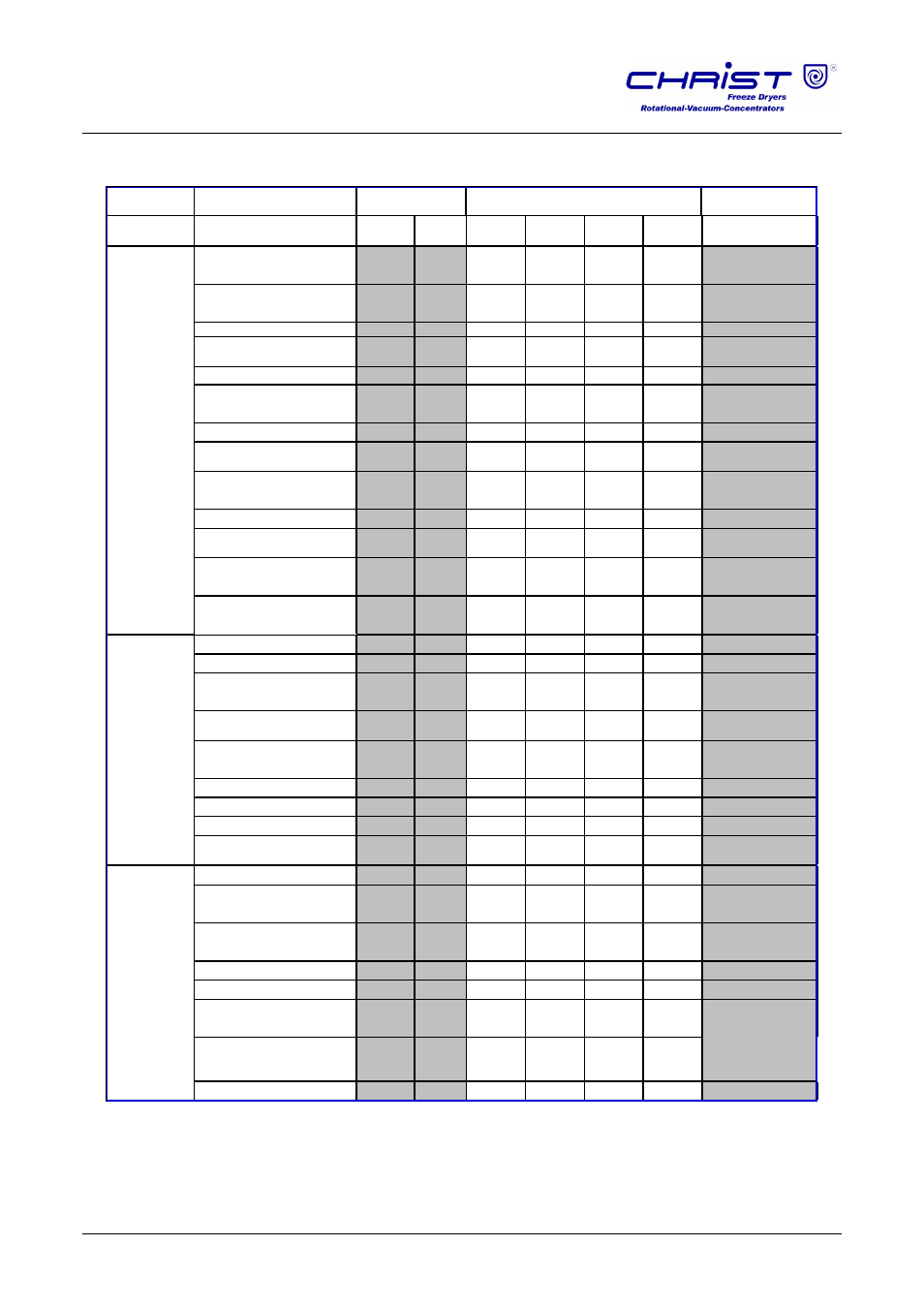

8.3 Maintenance schedule

System/

Component

Detail / Part

Repair/Rebuild

before

start

daily

inspection

replace

operation calibration

Drying chamber:

dry and clean

X

X

Steel bellow:

clean and undamaged

X

X

smooth travel

Silcone oil hoses and

X

X

leak free

Intermediate valve gasket

X

X

after 50

sterilisations

Shelves: pins

X

burr-free

smooth travel

Shelves: surface

clean and undamaged

X

Shelves: guardrails

X

Acrylic door surface

X

fogging,

cracks

Door gasket:

clean and undamaged

X

replace

after 50

sterilisations

Changing procedure

Door locks

X

burr-free

X

Changing procedure

Hinges

X

X

X

Adjust hinges after re-

placing door gasket

Door cover:

securely attached

X

X

Chamber sight glasses: clean,

illumination ok

X

X

Electrical cabinet

X

X

Leakages

X

X

Noise emission during operation

X

X

Dynamic gaskets: diaphragms

after 100

sterilisations

Static seals:

O-rings, clamp, KF

after 100

sterilisations

Loose wire

X

Cable tray closed

X

Framework

corrosion

Remove corrosion

Aeration filter

after 50

sterilisations

Pump: oil level

X

X

X

Pump: oil condition

(colour, contamination)

X

X

X

oil change

Oil mist filter:

emission of oil mist

X

X

X

Oil mist filter: oil level

X

cleaning

Final vacuum of instrument

X

Residue / particles inside oil

casing

X

Oil leakages at pump

X

X

after

10 years

Rotary shaft seal,

bearings,vanes, springs:

service life of 10 years

Vacuum leakage test

X

Inspection

Periodical Maintenance

Drying

Chamber -

Operator Side

Machine Room

- General

Vacuum

System