20 front panel interface, 3 rotary encoder, 4 dynamic function buttons – Lab.gruppen LM 44 User Manual

Page 26

20

Front Panel Interface

Lake LM Series Operation Manual Rev 1.2.8

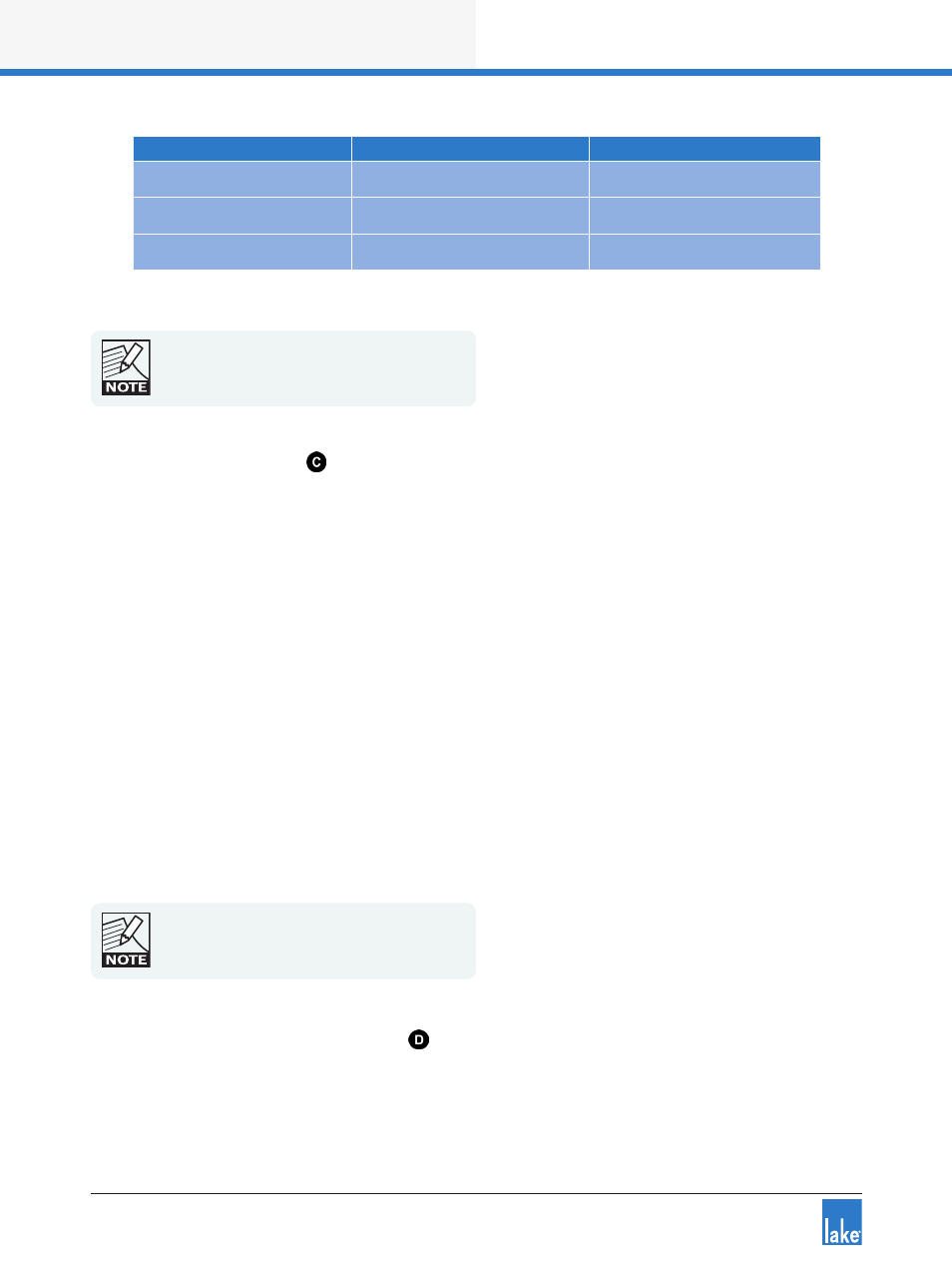

Warning Description

LCD Warning Text

Event Log Warning Text

Digital Clock Slipping

CLOCK SLIPPING

AES/Dante input clock slipping

Temperature Warning

TEMP WARNING

Temp Warning: DSP area

Controller Offline

CTRL OFFLINE

n/a

Table 6-2: Warnings (YELLOW FAULT / WARNING LED)

Module Input/Output mute status is indicated by

the dedicated mute button LEDs. Clipping is

indicated by the associated red meter segment.

Please refer to section 6.8 for further details.

6.7.3 Rotary Encoder

The rotary encoder is used to adjust parameters in conjunction with the selection made via the dynamic

function buttons and LCD menus. The ring around the rotary encoder illuminates when a selected parameter

is available for adjustment.

Turn the encoder clockwise to increase the selected parameter, or counter-clockwise to decrease the value.

Parameters with only two states (e.g. ON, OFF) are toggled by turning clockwise or counter-clockwise.

Some parameters enable simultaneous adjustment of a combination of input and output channels.

To select which channels are adjusted:

1. Press the associated soft button/s to select the parameter/s for editing.

A selected parameter is indicated by inverse text and background color.

2. Use the rotary encoder to change the value.

It is possible to select multiple parameters for simultaneous editing even if the values are different on each

channel. Turning the rotary encoder will adjust each parameter by the same increment. When in Meter

Mode, the rotary encoder allows the user to change between the available meter views.

Some menus permit parameters to be adjusted

across multiple channels simultaneously by default.

6.7.4 Dynamic Function Buttons

The buttons surrounding the display are unlabeled because their functions change according to the currently

selected menu or display.