Installation, Commissioning, 7filling the glycol circuit – Glow-worm Clearly Hybrid - Compact System User Manual

Page 17

0020096883_01 - 06/10 - Glow-worm

- 15 -

INSTALLATION

Commissioning

• Open all the hydraulic circuits’ valves.

7

Filling the glycol circuit

b

Warning! Do not dispose of glycol into drains

and the environment.

b

We recommend that you use propylene glycol

enriched with corrosive inhibitors.

• Mix 1 part propylene glycol with 2 parts water. This

mixture ensures antifreeze protection down to an exterior

temperature of -15 °C.

• Use an antifreeze test kit to ensure accurate dosing.

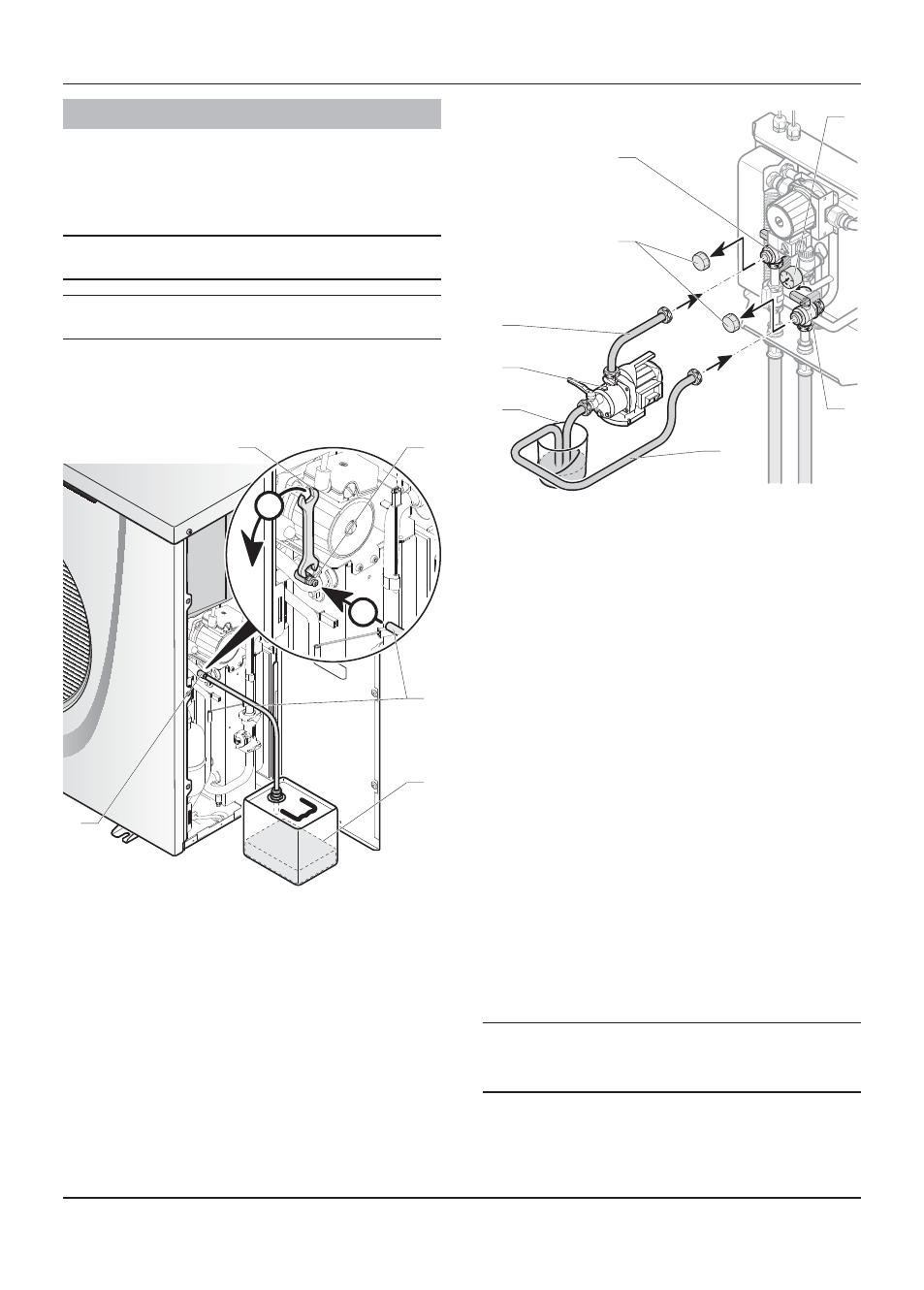

Ø14

A

B

1

3

4

1

2

Key

1 Air

trap

2

Ø 14 mm fl at wrench (*)

3 Hose

4 Deposit

(*)

(*) Not

included

• Connect one end of the hose (3) to the trap (1).

• Insert the other end of the hose (3) into the container (4) in

order to recover any residual brine during the fi lling of the

circuit.

• Using

a

fl at wrench (2), open the trap (1) a ¼ turn.

1

2

3

4

5

7

6

8

Key

1

Glycol container (*)

2

Filling pump (*)

3

Hose leading to the fi lling pump output (*).

4 Cap

5

3-way valve with shut-off valve for fi lling

6 Manometer

7

3-way valve with shut-off valve for fi lling

8

Hose leading to the fi lling pump return (*)

(*) Not supplied with the appliance

• In order to drain the glycol circuit after fi lling, use a fi ll pump

(2).

• Remove the caps (4) from the valves (5) and (7).

• Connect

the

fi lling pump hose (3) to the valve (5).

• Insert the hose (8) into the container and (1) and connect it

to the valve (7).

• Open valves (5) and (7) as shown in the illustration above.

• Start

the

fi ll pump (2) and fi ll the glycol circuit.

• Continue running the fi lling pump until completely purged of

air (8).

• Close the air trap located on the heat pump.

• Close the valve (7) and ensure the glycol circuit is left with

a pressure of between 1.5 and 2 bars with the aid of the

manometer (6).

• Close the valve (5) and stop the fi lling pump.

i

The level of glycol may decrease during the

fi rst month following the commissioning of the

installation. It may also vary in accordance with the

outdoor temperature.

Any residue of glycol solution should be kept in an appropriate

container to be re-used for the next fi lling.

• Ensure any leftover glycol solution is left with the end user

and retained in a safe place.