T-bar, P80/pp25 operator’s manual – Ditch Witch P80 User Manual

Page 47

Push Rods - 46

P80/PP25 Operator’s Manual

Setup

CMW

T-Bar

1.

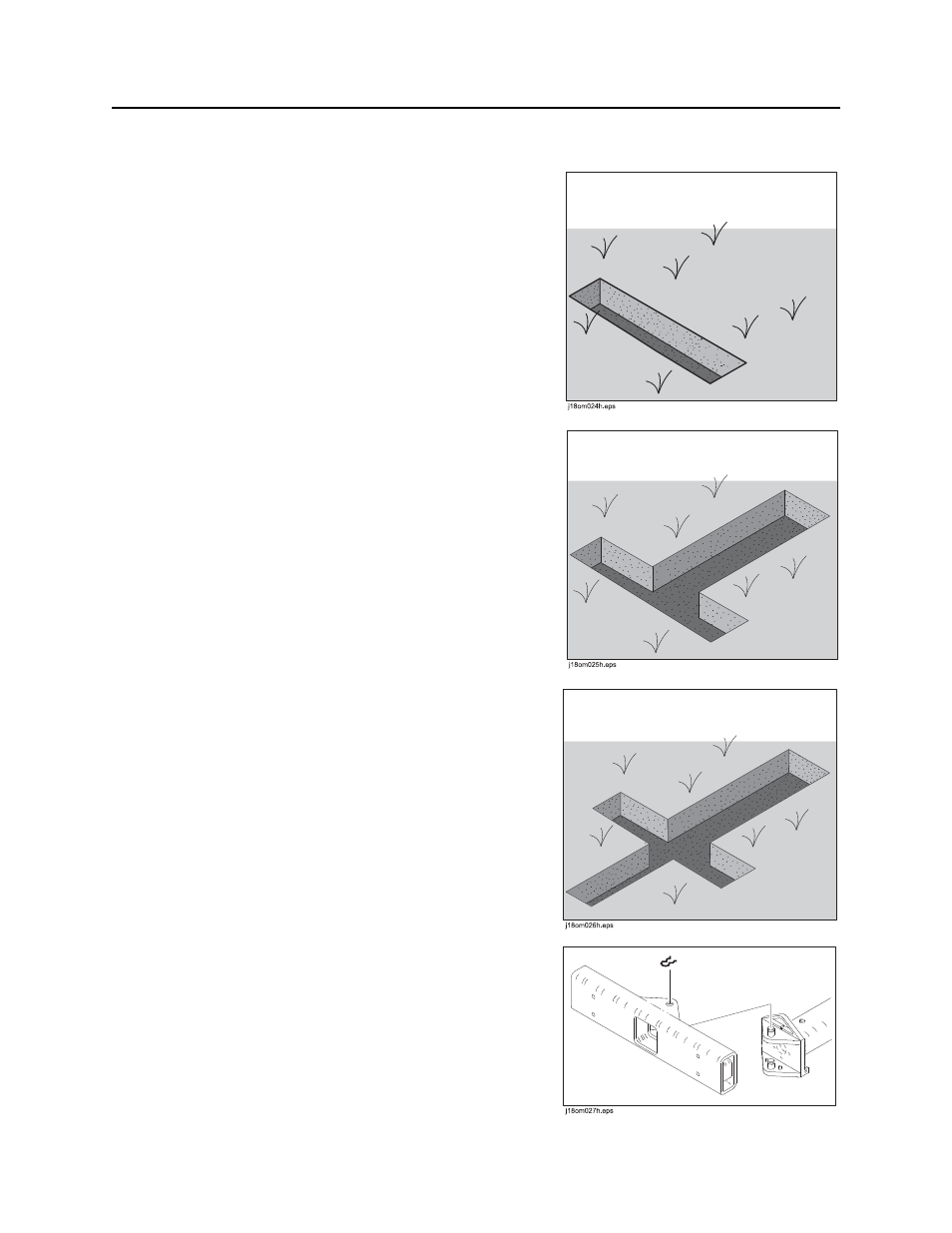

Dig T-Bar trench a minimum of 6” (150 mm) wide.

2.

Dig rod pusher trench a minimum of 9” (230 mm) wide. Do

not break edges or corners of T-Bar trench.

3.

Dig rod trench, as shown. Trench should be slightly longer

than rod being used. Level and compact trench floors.

4.

Dig target trench deep enough to meet bore path and long

enough to remove rod.

5.

Set T-bar on cylinder and install clip pins.

See also other documents in the category Ditch Witch Special machinery:

- JT5 (161 pages)

- JT922 (159 pages)

- JT9 (165 pages)

- JT20 (195 pages)

- JT1220 (201 pages)

- JT2020 (203 pages)

- JT25 (203 pages)

- JT30 (245 pages)

- JT60 (218 pages)

- JT100 (243 pages)

- AT Air Hammer (11 pages)

- TK Series Manual (61 pages)

- 8500 (77 pages)

- MR90 (121 pages)

- FT5 (28 pages)

- FM5 (57 pages)

- FM13V (46 pages)

- FM25 (67 pages)

- OnGrade (63 pages)

- FX20 (100 pages)

- FX25 (119 pages)

- FX30 (149 pages)

- FX50 (141 pages)

- FX60 (157 pages)

- MV800 (111 pages)

- RT Line (115 pages)

- RT30 (97 pages)

- RT45 (203 pages)

- RT55 (177 pages)

- RT100 (161 pages)

- RT115 (252 pages)

- RT120 (223 pages)

- Zahn (105 pages)

- RT80 (203 pages)

- RT115 Q (193 pages)

- RT120 Q (211 pages)

- 100SX (50 pages)

- 410SX (131 pages)

- SK350 (77 pages)

- SK750/SK755 (81 pages)

- SK850 (107 pages)

- SK850 Footings Machine (107 pages)

- 150RT (55 pages)

- 250RT (49 pages)