Exhaust duct and air intake – American Dryer Corp. AD-100 User Manual

Page 50

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Minimum

for I2"dia. ducts

for l6“dio ducts

670

560

450

340

230

115

1230

1025

820

615

410

205

R6URE I

FIGURE 2

To calculate area (in square inches) of round ducting:

Area = diameter (in inches)

X

Diameter (in inches) x .785. (Example:

area of 12" diameter duct = 12 x 12 x

.785 = 113 square inches.)

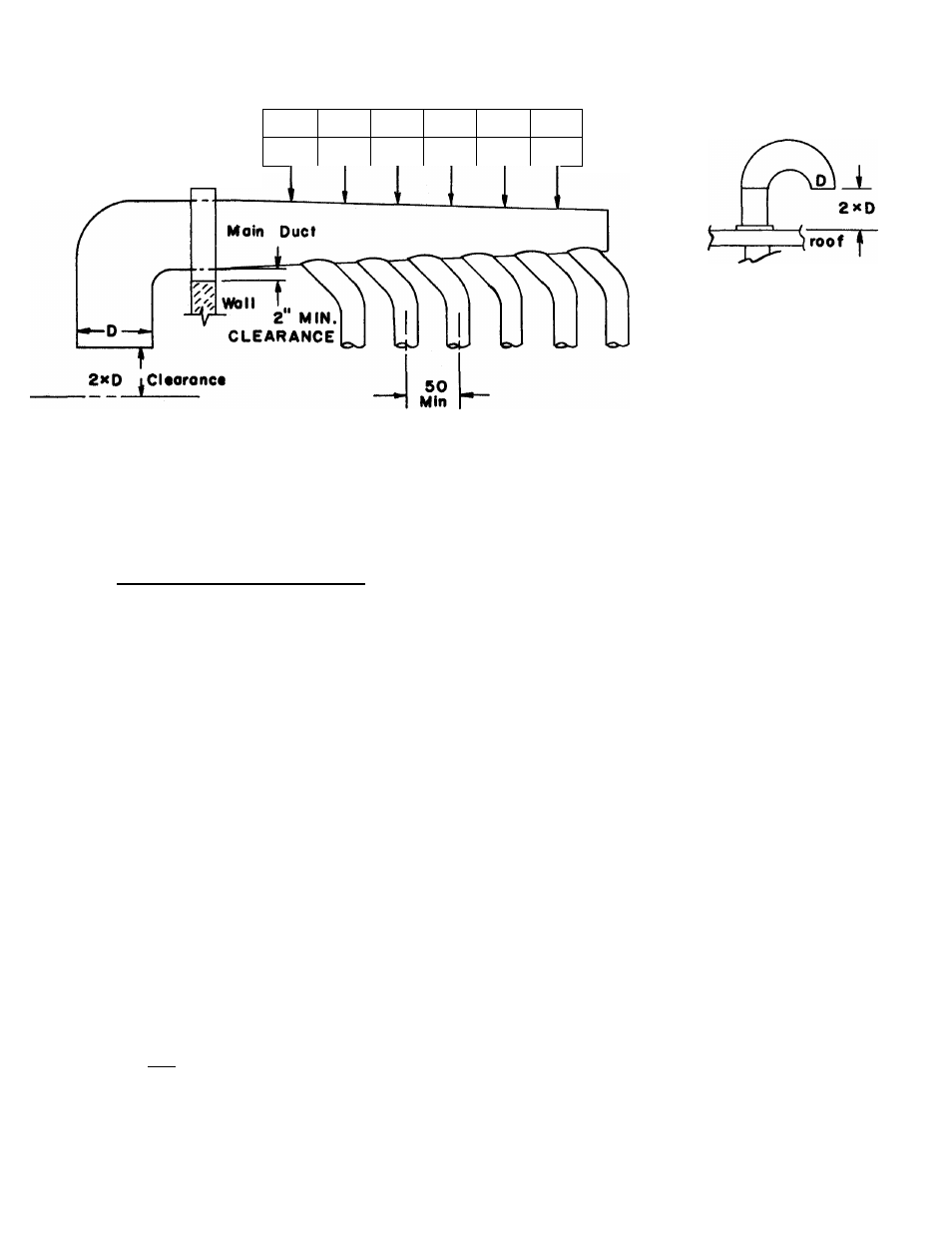

EXHAUST DUCT AND AIR INTAKE,

Where possible, it is desirable to provide

a separate exhaust air duct for each dryer. The duct should be 12" or 16"

diameter, depending upon the air outlet diameter of the dryer. The duct

should go as directly as possible to the outside air. Avoid right angle turns

in the ducting; use 30 degree or 45 degree angles Instead. The radius of the

elbows should preferably be 1 1/2 times the diameter of the duct. To protect

the outside end of the duct from the weather, it may be bent downward as indicated

in Figure 1. Leave at least twice the diameter of the duct clear between the duct

opening and the nearest obstruction. If the exhaust duct goes through the roof,

it may be protected from the weather by a hood, or by using a 180 degree turn to

point the opening down as indicated in Figure 2. In either case, allow at least

twice the diameter of the duct as clearance from the nearest obstruction as in

dicated above.

Do not use screens or caps on the outside opening of the exhaust duct. The

ducting should be smooth inside, with no projections from sheet metal screws or

other obstructions which will collect lint. When adding ducts, the duct to be

added should overlap the duct that it is to be connected to. Provide inspection

10-2