Throttle cable maintenance, Warning, Ignition system maintenance – Troy-Bilt 12069-7HP User Manual

Page 57: Spark plug maintenance, Tine shaft maintenance

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Your engine is equipped with a

dual element air cleaner that filters

the air twice before it enters the

carburetor to mix with the fuel.

The outer foam pre-cleaner filters

the air first; then the inner paper

element filters the air again.

It is very important that the fil

ters be kept clean and properly in

stalled at all times. See the air fil

ter system on your engine by refer

ring to Figure 5-39 or Photo 5-40.

Refer to the engine manufac

turer literature supplied with your

AIR CLEANER MAINTENANCE

THROTTLE CABLE

MAINTENANCE

WARNING

To help avoid personal injury,

stop the engine, wait for all

moving parts to come to a

complete stop,remove the

electric start key, disconnect

the spark plug wire and move

the wire away from the spark

piug, and let the engine and

muffler cool before adjusting

the throttle cable.

tiller for complete service and

maintenance information for the

air cleaner on your engine.

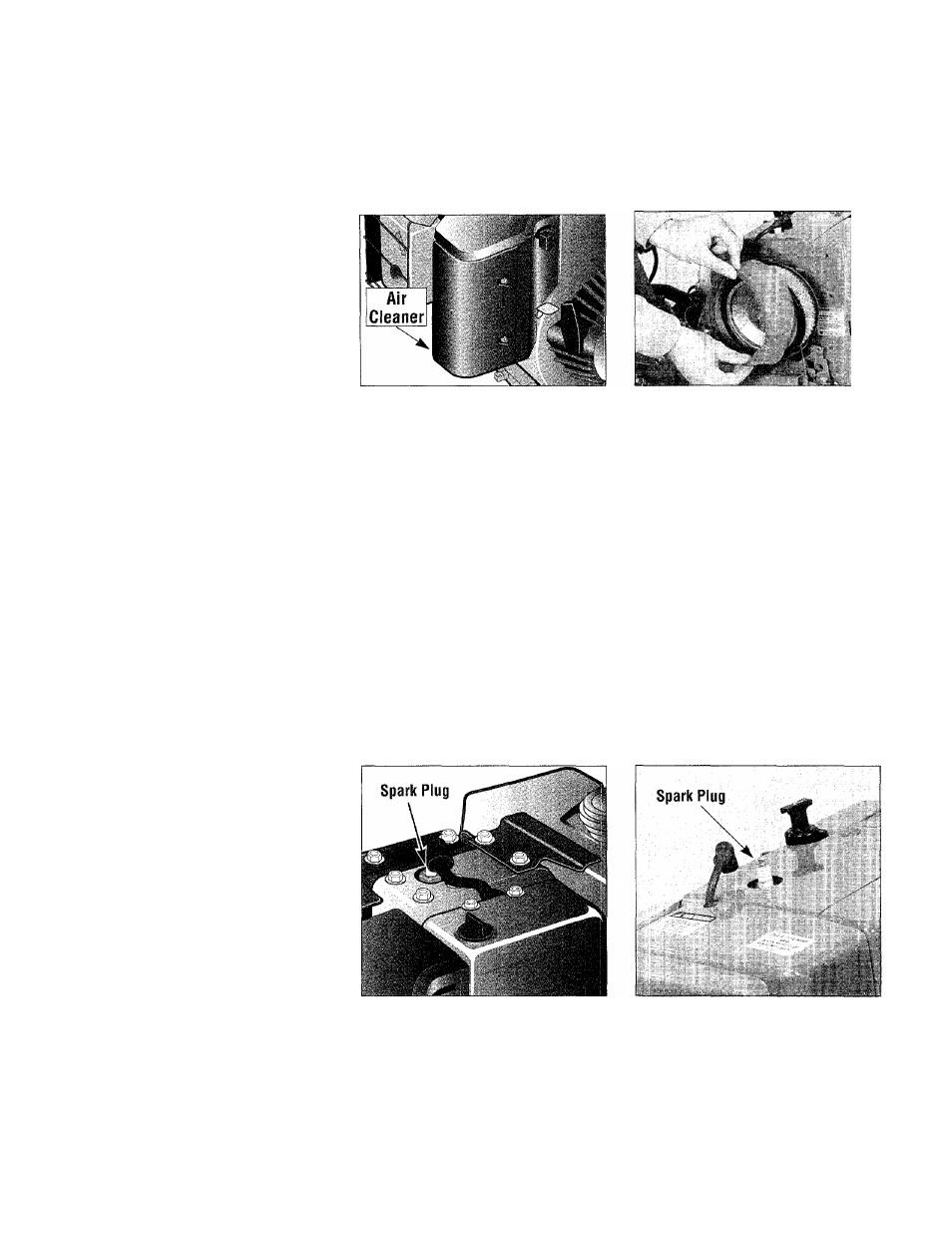

Figure 5-39: Air cleaner on the 7HP

Briggs & Stratton engine.

The throttle lever settings are

factory-adjusted, so unnecessary

adjustments should not be made.

However, if the engine does not

start or stop, or respond immedi

ately to various throttle lever set

tings, then adjustments may be

necessary. Please refer to the en

gine manufacturer literature sup

plied with your tiller for specific

adjustment instructions.

Of course, you may contact

your nearest authorized engine ser

vice dealer for throttle cable ad

Photo 5-40: Foam filter on the 8HP

Kohler engine.

justments by a qualified service

representative.

IGNITION SYSTEM

MAINTENANCE

Your engine is equipped with

electronic ignition. It does not

have a condenser or points, so

there is no need to perform any

regular “tune-up” maintenance on

this system other than adjusting or

replacing the spark plug.

SPARK PLUG

MAINTENANCE

The spark plug (see Figure 5-41

or 5-42) must be in good condition

for proper engine operation. Re

move and inspect the plug every

50 operating hours or annually,

whichever occurs first.

The correct electrode gap for the

Briggs & Stratton engine is .030"

and for the Kohler engine .025".

Check the gap with a feeler gauge.

Do not use a spark plug if the

porcelain is cracked, the electrodes

are pitted or burned, or other visi

ble damage is present.

Note:

Do

not wire brush or sand blast spark

plug to clean it - loose particles

can enter engine, causing damage!

Figure 5-41: Sparkplug (with boot

on) on the 7HP Briggs & Stratton

engine.

To replace the plug, first tighten

it securely by hand, then use a

spark plug wrench to tighten the

plug an extra 1/4 turn.

Photo 5-42: Spark plug on the 8HP

Kohler engine.

51