Tire and wheel maintenance, Warning, Engine oil maintenance – Troy-Bilt 12069-7HP User Manual

Page 56

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

After every 10 operating hours,

remove the left- and right-side

Bolo Tine holders and clear away

dirt and debris that have accumu

TINE SHAFT MAINTENANCE

lated on the tine shaft or inside the

tine holders. Please follow this

maintenance recommendation, as

debris can cause premature wear to

the tine shaft and its oil seals.

Refer to the previous tine holder

removal instructions (see previous

page). After cleaning away any

debris and removing old grease

from the tine shaft, apply fresh

grease to the tine shaft.

TIRE AND WHEEL MAINTENANCE

Check tire air pressure every 30

operating hours. The recom

mended pressure for tilling is 10-

to-20 psi (pounds per square inch).

Both tires should be inflated

equally. (Unequal pressure can

cause the tiller to pull to one side.)

WARNING

To help avoid personal injury,

stop the engine, wait for all

moving parts to come to a

complete stop, remove the

electric start key, disconnect

the spark plug wire and move

the wire away from the spark

plug, and let the engine and

muffler cool before removing

or replacing the wheels.

Removing the Wheels

Each wheel is secured by a roll

(spirol) pin that passes through the

ENGINE OIL MAINTENANCE

Change engine oil after first five

(5) hours of new operation. There

after, change the oil every ten (10)

operating hours. This may be

more often than your engine manu

facturer literature recommends,

however your tiller may be operat

ing in dirty or very dusty condi

tions.

Follow engine manufacturer lit

erature for specific oil changing

procedure, quantity of oil, and par

ticular grade and viscosity of oil to

use in your engine. Locations to

check the oil level and to drain the

oil are shown at right. Note that

there are two oil fill plugs (one on

each side) on the 7HP Briggs &

Stratton recoil start engine.

wheel hub and the wheel shaft.

Drive the roll pin out to remove a

wheel.

1. Prop the transmission up with a

sturdy block to raise the wheel you

want to remove off the ground.

2. Move the Wheel Speed Lever

to either SLOW or FAST position

to prevent the wheels from turning.

3. Use a 5/16" drift pin (or a blunt

point 16-penny nail) to drive the

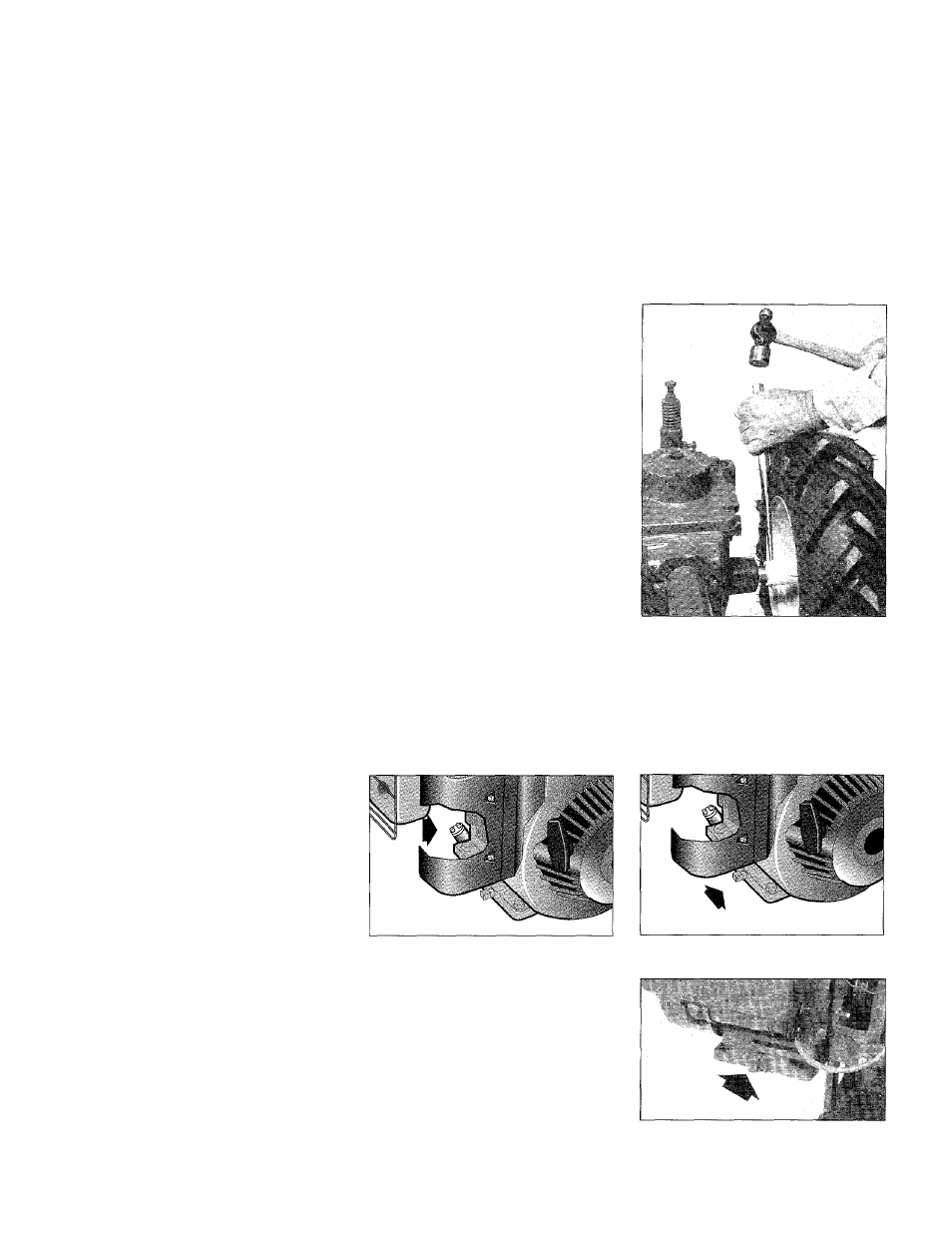

roll pin free. See Photo 5-34.

WARNING

Wear safety goggles when

driving the roll pin into or

from the wheel hub to protect

your eyes from the possibility

of flying metal particles.

Photo 5-34: Drive roll pin out to re

move wheel. Grease wheel shaft

before replacing wheel.

Figure 5-35: Oil fill plug on 7HP

Briggs & Stratton engine.

Figure 5-37: Oil drain plug location

on 7HP Briggs & Stratton engine.

fi-

Photo 5-36: Checking oil level on

8HP Kohler engine.

Photo 5-38: Location of oil drain

plug on 8HP Kohler engine.

56