H. trouble shooting chart – Poulan 195 User Manual

Page 23

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

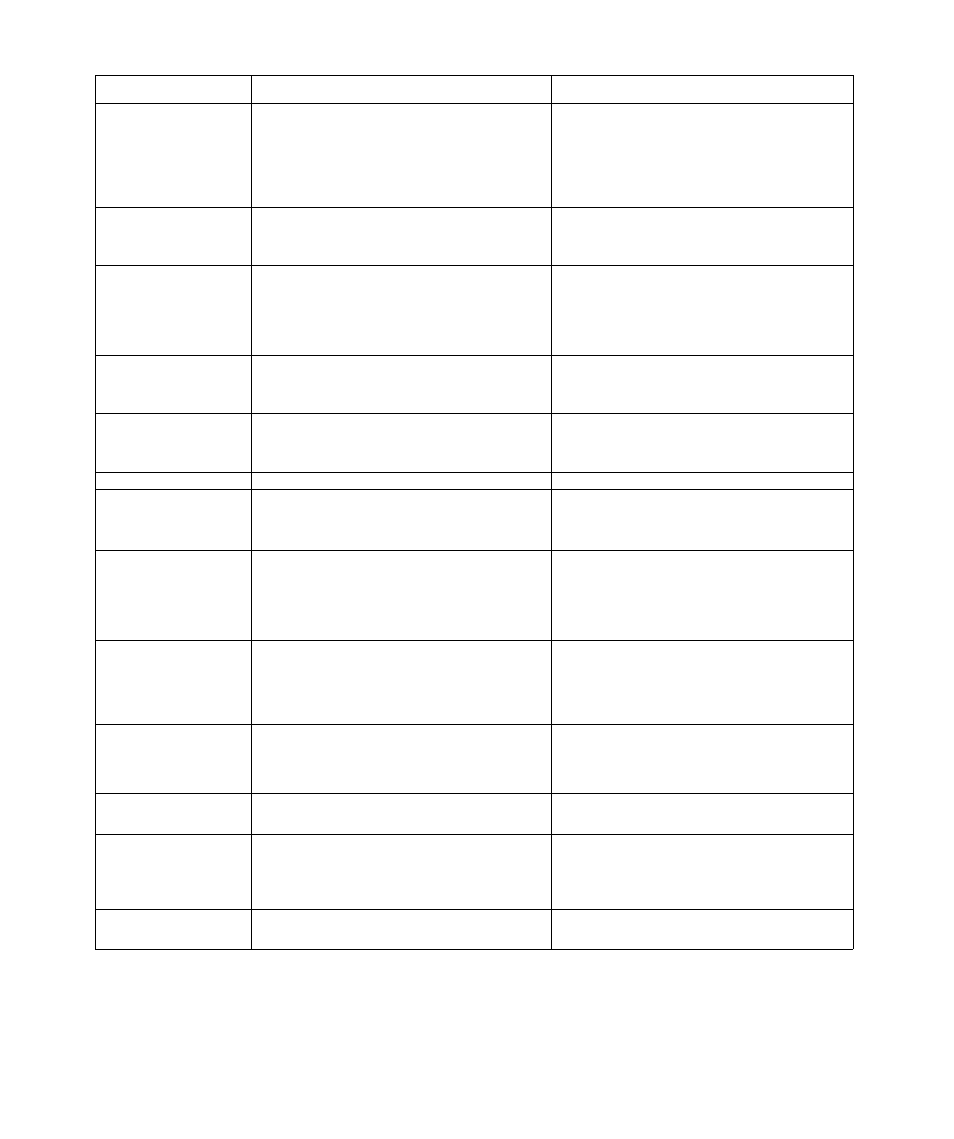

H. TROUBLE SHOOTING CHART

SYMPTOM

CAUSE

BEMEDY

Engine will not

start or will run

only for a few

seconds after

starting.

1. Fuel tank, empty.

2. Engine flooded.

3. Spark plug not firing.

4. f^el not reaching carburetor.

5. Carburetor requires adjustment.

6. None of the above.

1. Fin tank with correct fuel mixtme

2. See “Starting Instructions,”

3. Install new plug/check ignition system,

4. Clean fuel fflter; inspect fuel line.

5. See “Carbixretor Adjustments,”

6. Contact your Service Dealer.

Engine will not

idle properly.

1. Carburetor requires adjustment.

2 None of the above,

3. Throttle trigger screw too tight. -

1. See “Carburetor Adjustments,”

2. Contact your Authorized Service Dealer.

3. See the “Throttle Cable” section.

Engine will not

accelerate^aciks

power, or dies

under a load.

1. Air filter dirty.

2. Spark plug fouled.

3. Carburetor requiies adjustment.

4. Muffler outlets plumed.

5. None of the above.

1. Clean or replace air filter,

2. Clean or replace spark plug and re—gap.

3. See “Carburetor .^justments,”

4. Contact your Authorized Service Dealer.

5. Contact your Authorized Service Dealer.

Engine smokes

excessively

1. Air filter dirty,

2. Fuel mixture incorrect.

3. Carburetor requires adjustment.

1. Clean or replace air filter.

2. Refuel vrith correct fuel mixture.

3. See “Carburetor Adjustments.”

Engine runs hot.

1. Fuel mixture incorrect,

2. Carburetor requires adjustment.

3. Spark plug incorrect.

1. See “Fueling Your Unit.”

2. See “Carburetor Adjustments.”

3. Replace with correct plug.

"4r~None“ofthe’ahover

“4T-GontaetyourAisthorized-S^vic&Dem®c—~

Cutting attachment

turns at idle

speed.

1, Carburetor requires adjustment.

2, Throttle cable binding.

3, Clutch requires repair.

1. See “Carburetor Adjustments.”

2. Contact your Authorized Service Dealer.

3. Contact your Authorized Service Dealer,

Cutting attachment

stops under a load

or does not turn

when engine is

accelerated.

1. Drive Shaft not en^ged.

2. Drive shaft broken,

3. Carburetor requires adjustments,

4. Clutch requires repair.

1. See “Assembly, “Tube.”

2. Contact your Authorized Service Dealer,

3. See “Carburetor Adjustments.”

4. Contact your Autiiorized Service Dealer.

line does not

advance or breaks

while cutting.

1. line improperly routed in head.

2. line improperly wound onto spool.

3. Line size incorrect.

4. Too Httle line outside head.

5. Dirt accumulated on cover cut—outs.

1. Remove cover. Check line routing.

2. Rewind line tightly and evenly.

3. Use only POULANPRO .080” line.

4. Remove cover. Pull 4” of line to outside.

5. Clean cover cut-outs.

line welds on spool.

1. line size incorrect.

2. Incorrect spool.

3, Crowding line against material being cut.

4, Cutting at higher speed than neçesà^.

1. Use only POULAN PRO .080” line,

2. Use proper spooL

3. Cutvsdthtipofline,

4. Reduce cutting ^eed.

linereleases

continuously.

1. line improper^ routed m hea(L

1, Remove cover. Check line routing.

Line usage is

excessive.

1. Line improperly routed in head.

2. line size incorrect.

3. Cutting at hi^ speed around hard objects.

4. Crowdhig line against material being cut.

1, Remove cover. Check line routing.

2, Use only POULAN PRO .080” Ime.

3. Reduce speed around hard ohjecfs.

4. Cut with tip of fine.

line pulls b£u^

into head.

1. Too little line outside of head.

2. line size incorrect.

1. Remove cover. Pull 4” of line to outside,

2, Use only POULAN PRO .080” line.

- 2 3 -