Notes – Poulan 195 User Manual

Page 21

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

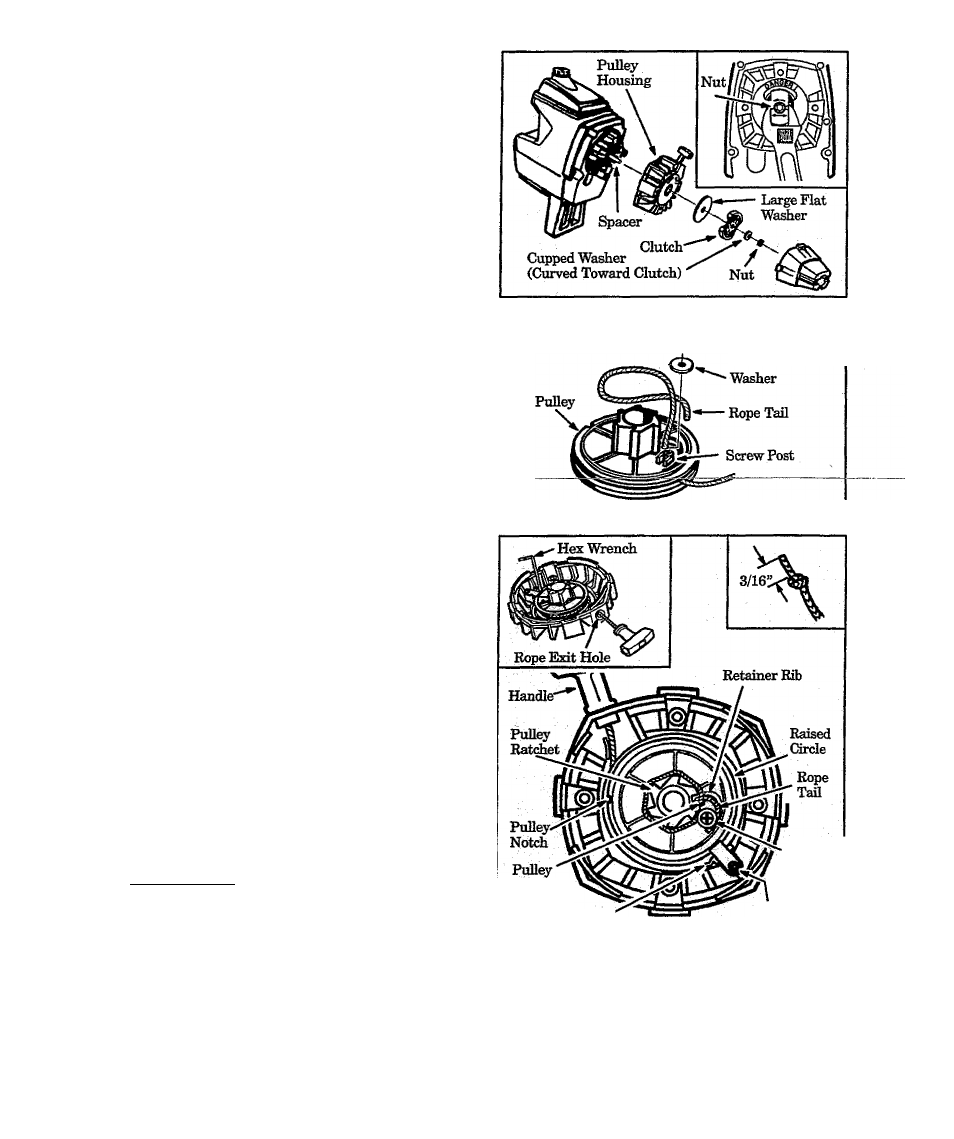

11. Remove the rope retainer screw. Figure 28, Re

move any remaining rope from around the pulley

ratchet. Figure 29.

12. Hold риДеу housing as shown in Figure 29 (in

set), Hand turn pulli^ clockwise as far as it will go.

13. Turn pulley counterclockwise until the pulley

notch is aligned with the housing notch next to the

pull^ tab and screw. Figure 29 .

14. Next, turn the puUqy one complete turn counter

clockwise until the notches are aligned again.

15,Insert the hex wrench into the hole formed by the

notches to hold the pulley in position. Fig

ure 29 (inset—upper left).

16. Use a 42” length of replacement rope.

17. Move away 10 feet (3 meters) from the fuel tank

with the replacement rope. Use a match and melt

both ends of the rope to prevent fireiying.

18. Pull melted ends through a thick, dean rag while

rope is still hot to obtain smooth, pointed ends.

lO.Insert one end of the rope throu^ the handle and

secш«-with-aJшot.JLíeave^a.ЗД6!lpigtailheЬшd_

the knot. Figure 29 (inset—upper right),

20.1nsert other end of the rope throu^ the rope exit

hole into the inside of the housing, into the puhey

and up through the pull^ hole. Figure 29.

21. Wrap the rope counterdockwise around the

pulley ratchet and tuck loose end under the rope

at the pull^ hole. Figures 28 & 29 . Leave a 1

inch tail laying flat on top of the pull^ between the

retainer rib and the retainer post. Figure 29 .

The rope tail must not extend beyond the raised

drde on the pulley to prevent interference with

thepuU^tab, Figure29.

22. Thread rope retainer screw into the screw post.

Figure 29. Do not overt^hten siaow.

23. HoId the rope taut at the rope exit hole so the

puH^wifl not move. Remove hex wrench. Allow

rope to rewind sb)ii»Zy.

24. Make sure spacer is in place. See Figure 27. Re

verse steps 1 throu^ 10 to re—assemble.

I CAUnON;

I

When reinstaUing the clutch^

ti^ten the nut until the cupped washer is

flattened against the clutch. Over or under

tighteningnut can cause engine damage.

Figure 27

Rope

Retainer Screw

Figure 28

Hole

Housing Notch

Rope

Retainer

Screw/Post

PuIl^Tab

and Screw

Figure 29

NOTES

- 2 1 -