Maintenance – Ariens GARDEN TRACTORS 931013 S-14G User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

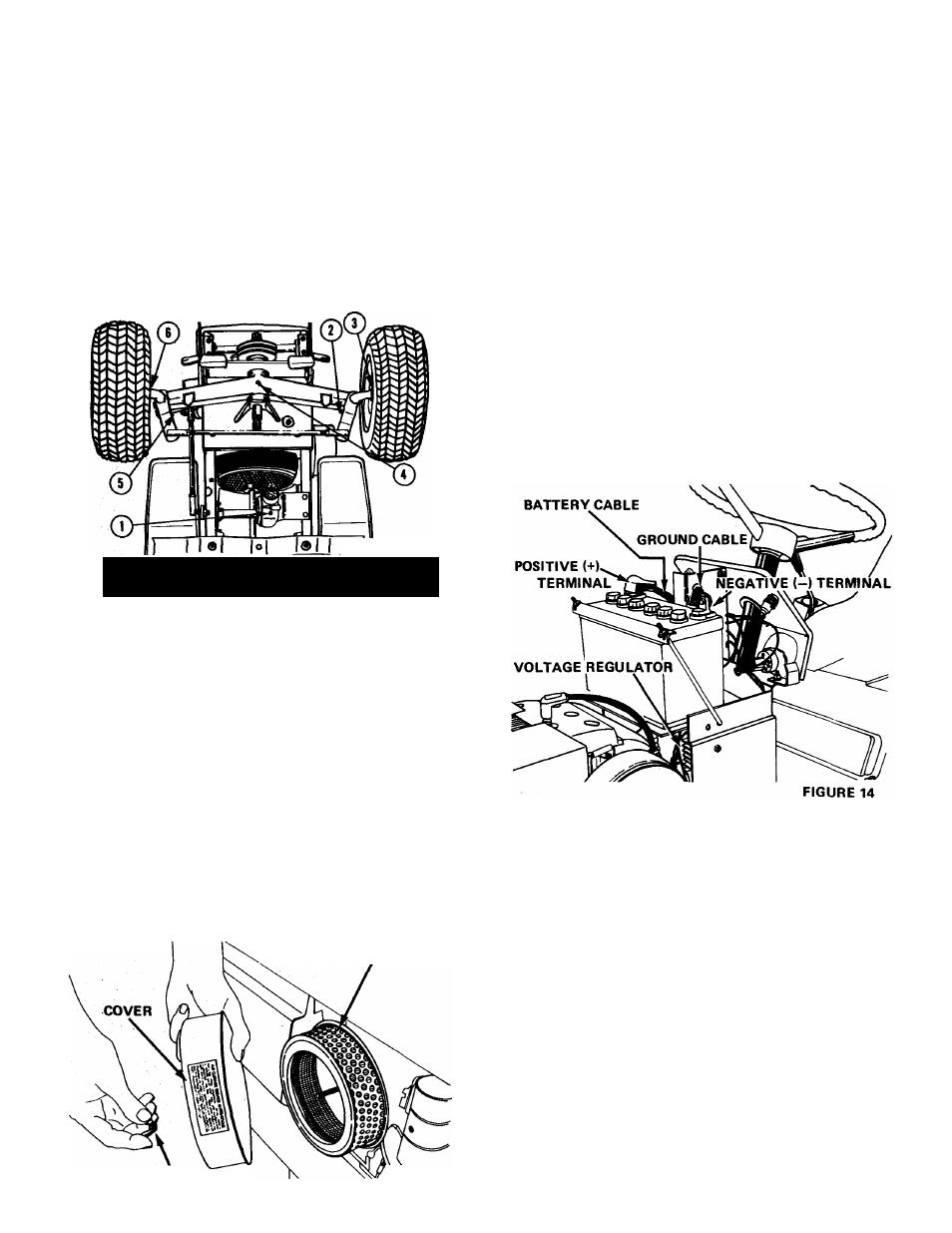

GREASE STEERING SYSTEM

Under normal conditions the steering system should be

lubricated every J50 hours of operation or quarterly whichever

occurs

first. The following list of

grease

fittings are identified

in Figure 12. Wipe each fitting clean before and after

lubrication! Use a good grade of general purpose grease such

as Ariens Multi-Purpose grease.

Rotate steering wheel clockwise until the spindle arm con

tacts the axle stop and fill gearbox until grease is forced out

around the cam follower adjusting screw.

O Steering gearbox.

® Left king pin.

©Front

L.H.

Wheel

©Axle pivot

© Right king pin.

© Front R.H. Wheel

FIGURE 12

MAINTENANCE

A

/VOTE

THAT

ALL

ENGINE

SERIAL

NUMBERS

HIGHER THAN THOSE LISTED BELOW HAVE A

GOVERNOR

SETTING

OF

3250

RPM,

NO

LOAD

(+ 75 RPM}. IDLE SET AT 1600 RPM, NO LOAD.

10 H.P.

MODEL NO. K241S SERIAL NO. 7541007

14H.P.

MODEL NO. K321S SERIAL NO. 8117916

HOUR METER

The hour meter is available as an optional accessory for all

Ariens Garden Tractors models.

The hour meter is located under the engine hood, on the

right side, just ahead of the dash panel. The hour meter will

record the actual time the engine operates. Keep a record of

hour meter readings in order to perform Maintenance and

Lubrication services at the recommended hourly intervals.

AIR FILTER SERVICE

Check the air filter daily or every 5 hours of operation.

When operating in extremely dusty conditions, check the air

filter daily. A precleaner is available. Consult the Engine

Manual.

AIR FILTER CARTRIDGE

To clean the cartridge, remove the wing nut and the cover,

shown in Figure 13. and then remove the cartridge. Gently

tap the cartridge on a flat surface. Do not use any liquid

cleaner to wash cartridge. Do not use compressed air to re

move dirt as this may rupture the cartridge.

Examine cartridge carefully and replace it with a new one

if it is bent, crushed or if there is a noticeable loss of power.

Re-assemble cartridge and cover making sure it seats around

the back plate. Install wing nut and tighten finger tight.

A

IMPORTANT:

removed.

Do not run engine with air fitter

BATTERY SERVICE

Check the battery electrolyte level once each month. Add

distilled water to bring the level to the bottom of the split

ring in the filter tube of each cell.

Each spring and fall remove corrosion from the terminals

and apply a light coat of grease, to the terminals. Keep

battery cables securely tightened to terminals and be sure

battery is properly fastened down in battery holder at all

times. Keeping battery clean will prolong battery life.

A

CAUTION:

Storage

batteries

give

off

highly

in

flammable hydrogen gas. Do not allow sparks or

flame near battery. Do not lay tools across battery

terminals which may cause a spark resuiting in an

expiosion.

Maintain the battery at full charge during storage and

during winter months to prevent freezing. When water is

added during freezing weather, run the engine at least one hour

to thoroughly mix the water and electrolyte.

When installing the battery, make certain that the ground

cable is connected to the negative (—) terminal on the battery,

see Figure 14. Be sure the battery cable is connected to the

positive (+) terminal.

A

WARNING: Reversed battery cables or reversed

cables from a battery charger or booster battery can

cause damage to the regulator rectifier (Figure 16).

Always disconnect plug from the regulator rectifier

before using a charger, booster battery or when

electric welding is done on the tractor.

WING NUT

FIGURE 13