Clean the mower housing and discharge chute, Check tire pressure, Check bolts, screws and nuts – Troy-Bilt 1900678 User Manual

Page 27: Lubrication

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

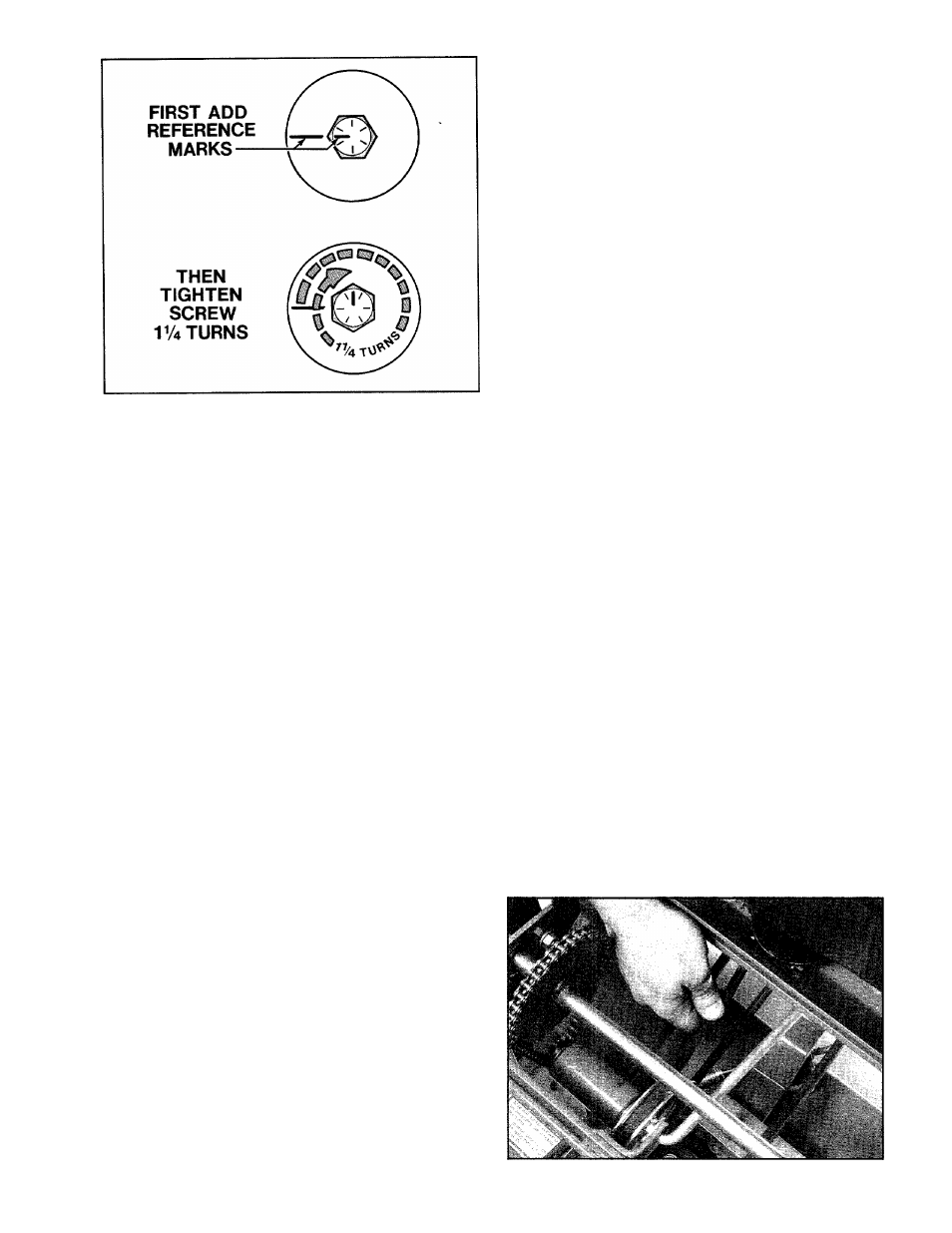

Figure 5-10: If you do not have a torque wrench, tighten

mounting screw as shown above.

H. Remove any rags you may have used to cover the

blade and then lower the front of the mower to the

ground.

I. Reconnect the spark plug wire (and open the fuel

valve on the 8 HP engine) before attempting to start

the engine.

NOTE: Use only a “GRADE 8” screw to mount the

blade. Refer to your Parts Catalog if a replacement

screw is needed.

CLEAN THE MOW ER HOUSING AND

DISCHARGE CHUTE

Clean the underside of the mower housing and the

discharge chute after every mowing. More frequent

cleaning may be necessary under heavy cutting con

ditions.

B

CAUTION: To avoid personal injury, stop the

engine, disconnect the spark plug wire, keep

the wire away from the spark plug, and allow the

engine and muffler to cool before cleaning the

mower housing or discharge chute.

A. Raise the front of the mower about 6" by propping

up the mower deck with sturdy blocks.

B. Spray the underside of the housing and the dis

charge chute with a garden hose to remove clippings

and dirt (avoid spraying the engine or any electrical

connections).

CHECK TIRE PRESSURE

Use a pocket-type tire pressure gage to check the in

flation pressures in the rear tires. The tires should be

equally Inflated to between 25-30 psi. Check the infla

tion pressures after every 10 hours of operation or once

a week, whichever occurs sooner.

CHECK BOLTS, SCREW S AND NUTS

Before each use, check all bolts, screws and nuts for

tightness and keep them tightened securely at all times.

LUBRICATION

Clean and add several drops of light oil to the follow

ing points after every 10 operating hours:

1. All linkages and pivot points.

2. Drive chain on self-propelled models.

3. Both ends of the throttle control cable.

4. Wheel mounting bolts and studs.

5. The spring-loaded dowel pin found on the inside

edge of the two friction drive rollers (see Ref. Nos. 100

and 98 in your Parts Catalog for the location of these

two parts). After oiling, rotate the friction drive roilers to

help spread the oil on the pins.

W HEEL DRIVE BELT TENSION

(Self-Propelled Models Only)

Check the wheel drive belt tension after each 10

hours of operation. Due to normal stretch and wear on

the belt, periodic adjustments may be required. While

checking the tension, also look for obvious signs of

wear such as cracks, cuts or fraying. If the belt is in

poor condition, order a replacement from the Garden

Way Parts Department. This is a special belt made for

your mower and is not available locally.

B

CAUTION: Stop the engine, disconnect the

spark plug wire, and allovi^ the engine and

muffler to cool before inspecting or servicing the

drive belt.

TOOLS NEEDED: 7/16" and

1

/

2

" Wrenches, Flat Blade

Screwdriver, Rubber Mallet.

A.

Remove the belt/pulley safety cover by removing

the three hex nuts and two self-tapping screws.

B. To check for correct tension, use your thumb to

press down in the center of the belt as shown in Photo

5-11. The tension is correct if the belt deflects between

V

2

" to 5/8", under moderate thumb pressure (6-8 lbs.

with V

2

" deflection).

Photo 5-11:

Check wheel drive belt tension.

25