Sharpening or replacing the mower blade – Troy-Bilt 1900678 User Manual

Page 26

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

C. Adjust the handlebars to the desired height by

following Steps D and E of the “Attach Handlebars” in

structions on Page 6.

D. Whenever the handiebar height is changed, the

position of the control rod clevis must be changed ac-

cordingiy, reiative to the height position of the handle

bars. To change the clevis to the correct bellcrank hoie,

follow Steps B, C, E, F, G and H of the “Attach Wheel

Drive Control Rod” instructions on Pages 6 and 7.

E. After securing the control rod clevis to the bellcrank

with the clevis pin and spring clip, remove the screw

and nut from the bellcrank alignment holes. Be sure to

save the screw and nut for any future handlebar height

adjustments.

F. With the wheel drive lever in the upright, NEUTRAL

position, check that the clearance between the rollers

and the tires is correct. See “Adjusting Wheel Drive

Traction” on Page 22.

SHARPENING OR REPLACING

THE MOW ER BLADE

Check the condition of the mower blade before each

use. If it is dull or slightly nicked, it should be sharpened

as explained below. A deformed, cracked, or badly nick

ed blade should be replaced with a new one. While

checking the blade, also check that the blade mounting

screw is tightened securely.

cause excessive vibration which could result in engine

damage, or personal injury if the blade should break.

A<

.CAUTION

To avoid porsonni injury, stop the engine, dis

connect the spar< plug wire, keep the wire

away from the spark plug, and allow the engine

and muffler :o coo' before inspecting or servic

ing the blade.

To avoid personal injury from contact with the

sharpened blade, wear heavy gloves or wrap

the blade with ‘.hick rags before working neat it.

To prevent a potential fi''e hazard from possible

gasoline spills, make certain that the area iS

well ventilated and that you keep smokincj

materials, soarks or Fame away.

TOOLS NEEDED: 9/16" Wrench, Flat Metal File.

A. Raise the front of the mower by anchoring the han

dlebars securely or by propping up the mower with stur

dy blocks. On the 8 HP engine only, turn the fuel valve

to the OFF position before tilting the mower back.

B. To remove the blade, hold the blade with one hand

and remove the screw and conical (belleville) washer

using a 9/16" wrench. See Photo 5-8.

C. If the blade needs sharpening, use a file to sharpen

the cutting edge at both ends of the blade. Sharpen

along the original cutting angle, filing in the direction of

the cutting edge only. To maintain proper blade balance,

be sure to remove the same amount of material from

both cutting edges. Check the blade for balance by

balancing it on the round shaft of a pen or pencil. If the

blade cannot be balanced properly, it should be

replaced with a new blade. An unbalanced blade can

Photo 5-8: Remove screw and conical washer.

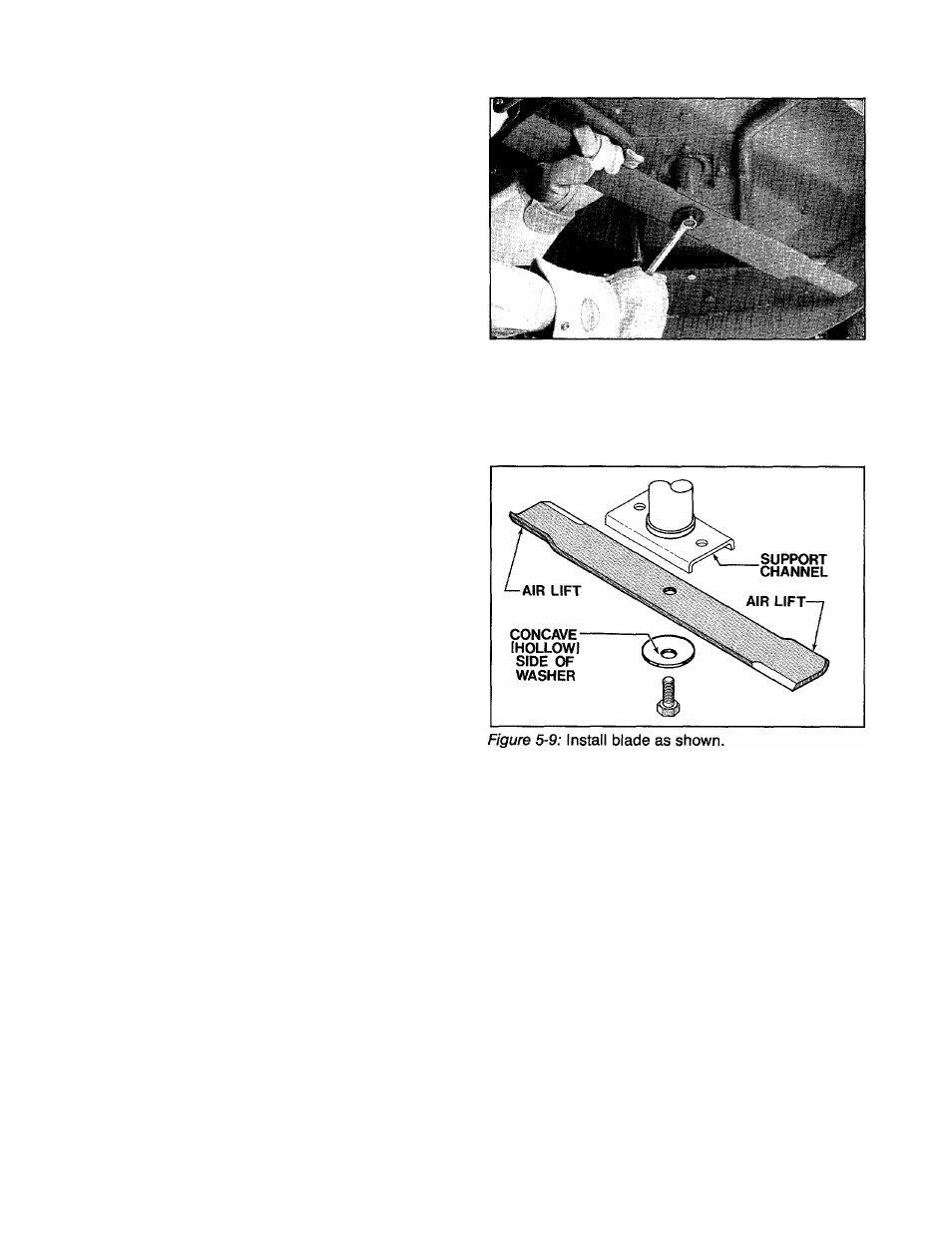

D. To reinstall the blade, first place the conical washer

on the mounting screw, making certain that the con

cave side (hollowed side) of the washer is facing away

from the head of the screw. See Figure 5-9.

IMPORTANT

Do not apply lubricant of any kind to the screw threads.

The screw must be dry in order to work properly.

E. Place the blade in the support channel of the blade

mounting bracket, making certain that the two air lifts

at each end of the blade are pointing upward, toward

the top of the mower deck.

F. Using your fingers only, tighten the screw finger-

tight while gently rocking the blade up and down to

properly seat the blade.

G. Tighten the screw to 38 to 42 ft. lbs. torque. If you

do not have a torque wrench, use the following method

to ensure that the screw is tightened correctly:

1. Using chalk, a grease marker, or paint, draw a

thin line across one-half of the screw head as

shown in Figure 5-10. Draw a similar reference

line on the washer, directly opposite the line on

the screw.

2. Be sure that the screw is tightened finger-tight

as explained in Step F above. Then using the two

lines as reference marks, tighten the screw VA

turns.

24