SINGER W510 User Manual

Page 31

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

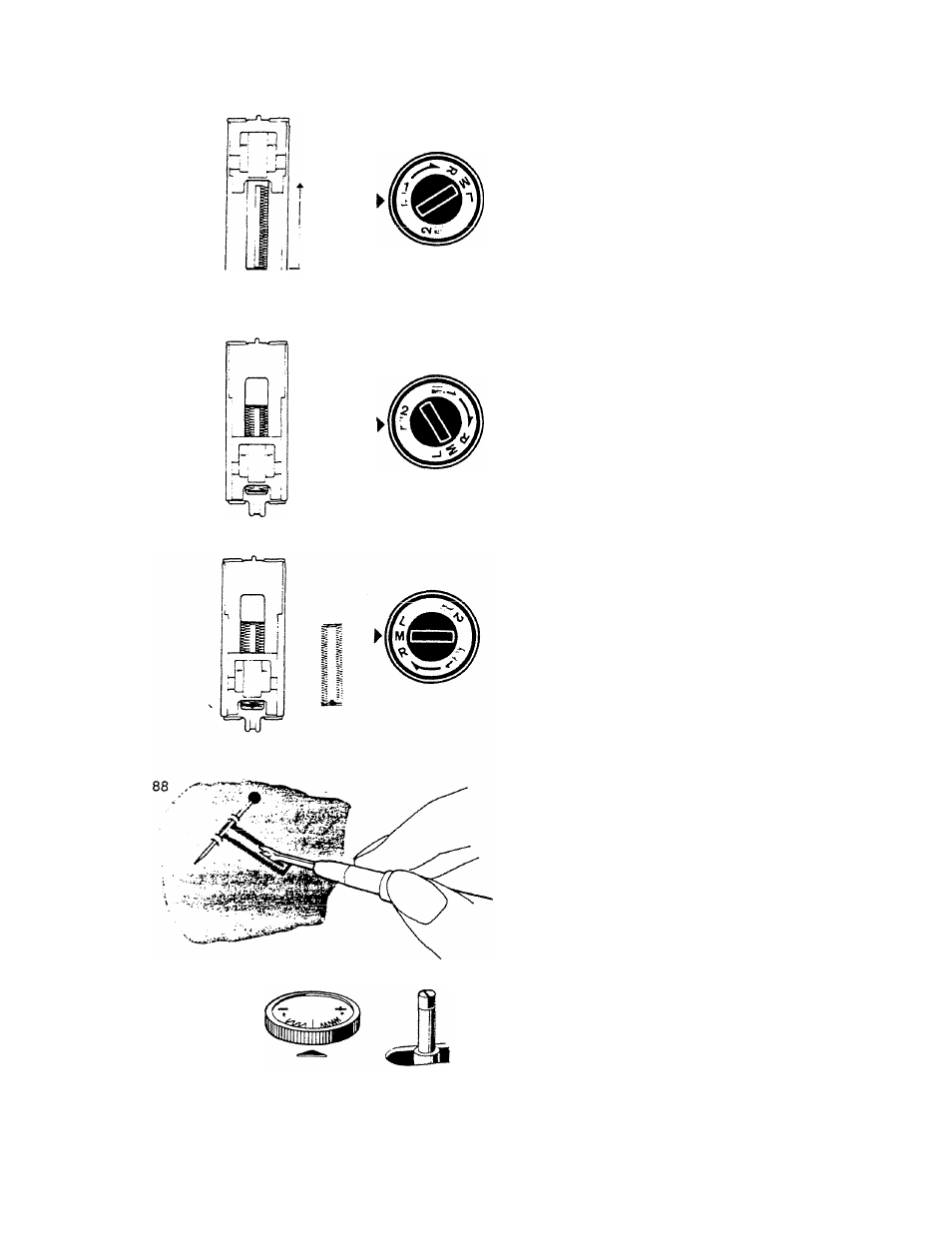

87

This buttonhole eliminates the need for

pivoting the fabric. It is used most often

on light and medium woven fabrics.

1

. Set the buttonhole control dial at the

first buttonhole picture. Lower the

needle into the mark at the front end

of the buttonhole. Lower the presser

foot. A few stitches will be made for

the bartack, then the stitching will

automatically continue up the right

side of the buttonhole in reverse.

Stop when the stitching reaches the

top end of marked buttonhole. At

this position the machine will be

sewing in reverse.

2.

With the needle up, select the second

buttonhole picture. A few bartack

stitches will be made then, stitches will

continue forward sewing the left side

of the buttonhole. White nylon slide

will run into the cardboard to prevent

sewing into the bartack. (Fig. 87)

3.

To lock the stitch, m.ake sure the

needle is out of the fabric. Make sure

the buttonhole control dial is at M

and take a few stitches.

4.

-Score the buttonhole with the back

edge of the seam ripper several times.

To

prevent

cutting

through

the

bartack, insert a straight pin through

the bartack. Cut buttonhole open

with the seam ripper. (Fig.

88

)

,'Vore.- Stitch IVidth Control shouui

ti'ivcys hr at "

this uuttonnole.

BUILT-IN BUTTONHOLER

Pattern;

Length: Buttonhole

Width; 0

F 66d D og! U p

Pressure: Normal

Foot; Buttonhole

Needle Position:

^vir-v.

1 2

■M

□TJ‘

Adjustment of stitch density:

Check the stitch density on a scrap of

fabric. If density is too open or too close,

re-adjust first the density of the left side

by stitch length dial, and, if the right side

density is not same as the left side, the

density of the right side may be varied

with a compensator dial located near the

bobbin winder, in order to make it match

with the left side.

29