Trouble shooting chart, Recommended accessories, Trouble shooting – Sears 113.206931 User Manual

Page 26: Le shooting

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

le shooting

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH

"OFF" AND REMOVE

PLUG

FROM POWER SOURCE

OUTLET BEFORE TROUBLE SHOOTING YOUR JOIN

TER-PLANER.

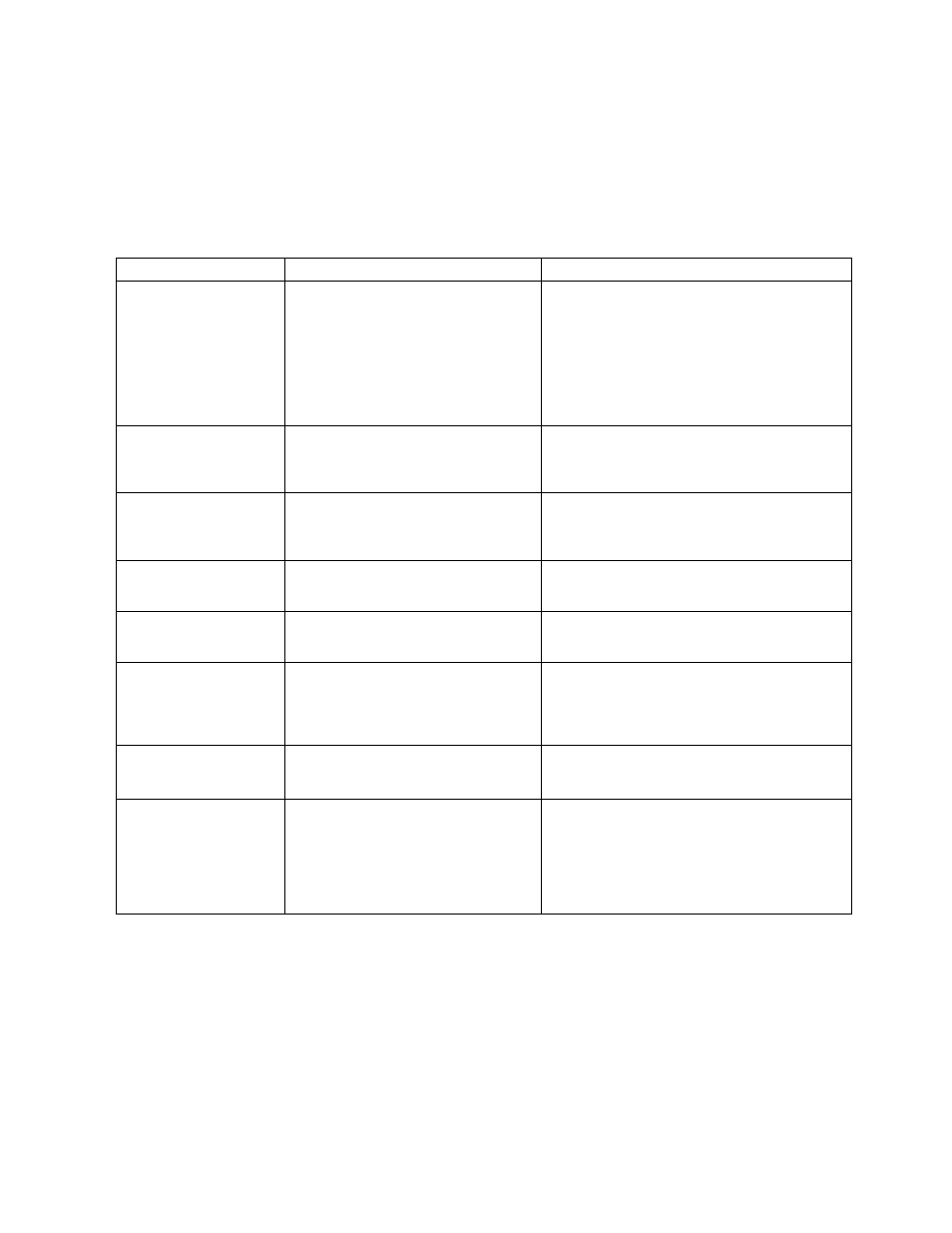

TROUBLE SHOOTING CHART

TROUBLE

PROBABLE CAUSE

REMEDY

Motor will not run.

1. Defective dn-Off switch.

Defective switch cord.

Defective switch box receptacle.

2. Motor protector open, {only if

your motor is equipped with an

overload protector).

: Other cause ............................

1, Replace defective parts before using

machine again.

2. Consult Sears Service. Any attempt to

repair this motor may create a HAZARD

unless repair is done by a qualified service

technician. Repair service is available at your

nearest Sears Store.

Wood strikes outfeed

table after passing over

cutter head.

Blades irnproperly adjusted below

surface of outfeed table.

Re-adjust blades, see Maintenance section.

Ripples on planed

surface.

1. One blade set higher than other.

2. Feeding wood too fast.

1. Re-adjust blades, see Maintenance

section.

2; Feed wood slower.

Planed surface not

straight.

Infeed table out of adjústment.

Re-adjust infeed table, see Getting To Know

your Jointer Planer section.

Excessive gouging at end

of cut. '

Blades set too high above outfeed

table. :

Reset blades, see Maintenance section.

90° and 45® cuts

inaccurate.

T, Fence stops not adjusted properly.

2. Fence slide bracket not even with

„■ Table.

1. Re-adjust fence stops, see Getting To

Know your Jointer Planer section.

2. Re-adjust slide bracket, see Getting To

Know your Jointer Planer section.

Infeed table loose.

1, Dovetail spacer requires adjustment.

2i Fernale dovetail loose from table.

1. Tighten screw, key 10, see fig. 2, Parts List.

2. Tighten screws, key 18, see fig. 2, Parts List.

Cutter guard does not

function properly.

T. Return spring broken; or spring

has been weakened.

2. Improper assembly of spring or

guard mounting.

1. Replace spring immediately. See

Maintenance section.

2. See Maintenance section.

RECOMMENDED ACCESSORIES

ITEM

CAT. ISIO.

Steel Legs .. ..................................... 9-22245

Floor Stand . ..... .......................................................... 9-22216

Cutter Blades . .... ...... .......................................... 9-2293

Power TooT Know-how Handbooks

. '

. ,

Radial Saw ., ... ...........:...................... ........ .. -.. .. 9-.2917

Table Saw. . . . . .

..................... 9.2918'

Knife Setting Gauge ......................... . .9-2647

Chip Collector ................................. ..................... , 9-29977

The above recommended accessories are current and were

available at the tirne this manual was printed.

26