Step 6 — make piping connections – Carrier 38AN User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

'2 1/2" TYP

□IA

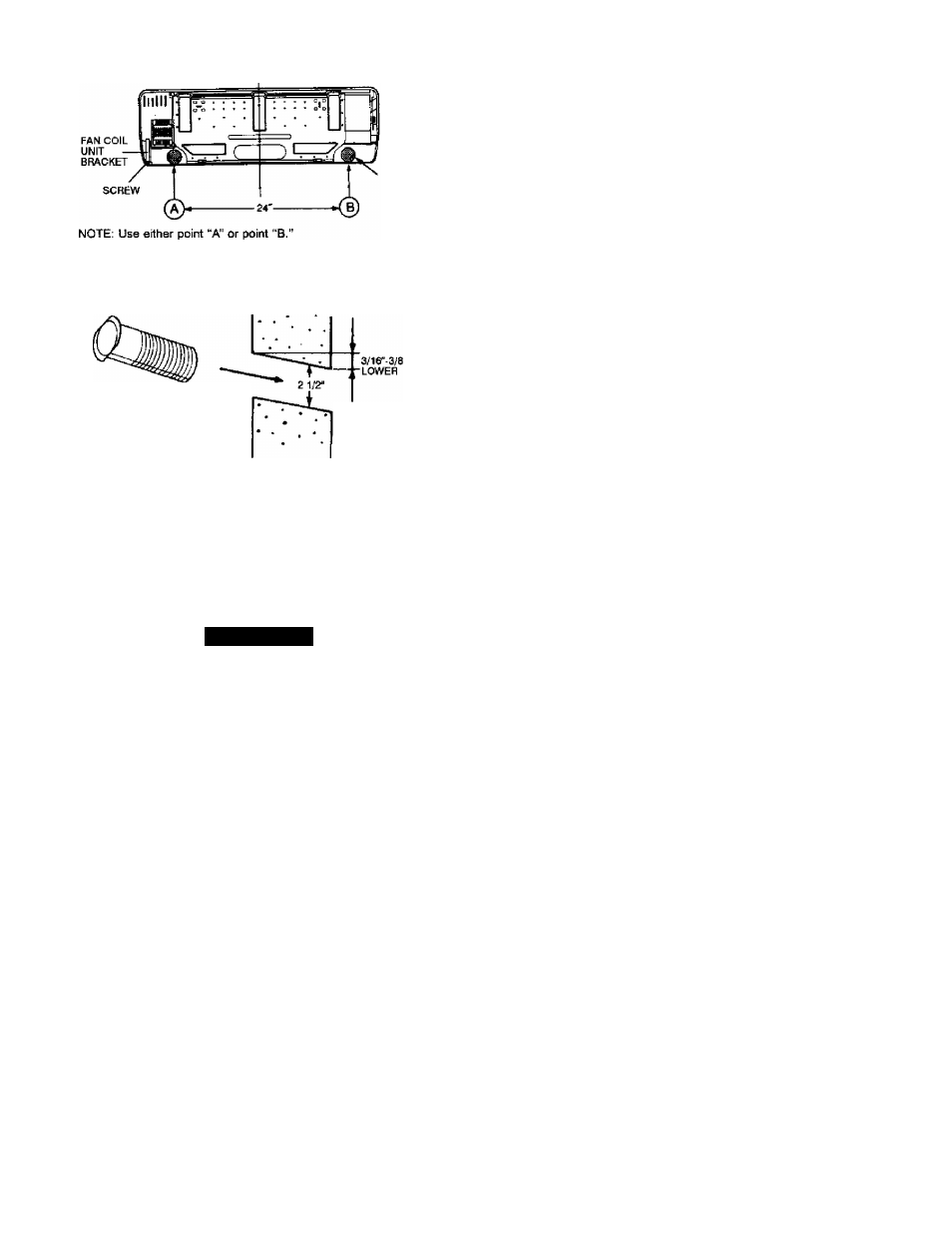

Fig. 8 — Wall Hole Location For Fan Coil Unit

Rear Piping (Size 009 Shown)

WALL SLEEVE

(FACTORY SUPPLIED)

(INDOOR SIDE) • WALL . (OLTTDOOR SIDE)

NOTE: Slope condensate line at a minimum pitch of

V*

in. per foot.

Fig. 9 — Piping Hole

Step 5 — Connect Refrigerant Piping

— Refer

to Tables 4A-4D for correct piping sizes. The length of re

frigerant pipe depends on the unit placement and building

structure — run pipes as directly as possible. Piping lengths

must not exceed 35 ft of total run.

CAUTION

DO NOT BURY MORE THAN 36 IN. OF REFRIG

ERANT PIPE IN THE GROUND. If any section of pipe

is buried, there must be a 6-in. vertical rise to the valve

connections on the outdoor unit. If more than the rec

ommended length is buried, refrigerant may migrate to

cooler, buried section during extended periods of unit

shutdown, causing refrigerant slugging and possible com

pressor damage at start-up.

If it has not yet been removed, remove indoor section front

panel by removing the Phillips head screws located at the

bottom of the air outlet. It may be necessary to rotate the

louvers to locate the mounting screws.

Make piping connections:

NOTE: Right rear piping connections are the preferred

configuration.

RIGHT REAR AND BOTTOM PIPING CONNECTIONS

1. Carefully separate the tubing and condensate drain tube

from the shipping brackets.

2. Be careful not to bend or kink the tubing. Gently rotate

the tubing 90 degrees.

3. Carefully position the indoor section onto the wall bracket.

Be sure the tubing and drain mbe are routed through the

piping hole in the wall.

4. Check that the indoor section is moxmted level to ensure

proper condensate drainage and to avoid possible water

damage. Be sure the drain tube is sloped toward the out

side and is not kinked or bent. Ensure that any drain ex

tension is made outside the wall.

RIGHT SIDE PIPING CONNECTIONS

1. Carefully remove the tubing and the condensate drain tube

from the shipping brackets.

2. Be careful not to bend or kink the tubing. Gently rotate

the tubing 180 degrees.

3. Using a hand tube bender, carefully bend the tube ends

until they coincide with the raceway opening.

4. Carefully position the indoor section onto the wall bracket.

Be sure the tubing and drain tube are routed through the

piping hole in the wall.

5. Check that the indoor section is mounted level to ensure

proper condensate drainage and to avoid possible water

damage. Be sure the drain tube is sloped toward the out

side and is not kinked or bent. Ensure that any drain ex

tension is made outside the wall.

LEFT SIDE PIPING CONNECTIONS

1. Place indoor unit on wall bracket.

2. Mark where the tube flare connection points end on the

wall.

3. Remove the indoor section from the wall bracket.

4. Route the interconnecting tubing and the drain tube ex

tension through the wall sleeve.

5. Using a hand tube bender, carefully bend the tubes until

they coincide with the position of the flare connection points

on the wall.

6. Secure indoor section to the wall bracket.

7. Connect the drain tube extension to the condensate drain

tube.

8. Carefully position the indoor section onto the wall bracket.

Be sure the tubing and the drain tube are routed through

the piping hole in the wall.

9. Check that the indoor section is mounted level, to ensure

proper condensate drainage and to avoid possible water

damage. Be sure the drain tube is sloped toward the out

side and is not kinked or bent. Ensure that any drain ex

tension is made outside the wall.

ALL TYPES PIPING CONNECTIONS

NOTE: After tubing is routed through wall sleeve, install the

factoiy-supplied w5l cap around tubing components and into

the 2Y2-in. hole. Do not fill air gaps yet with insulation or

caulking as this space is helpful when connecting tubing to

outdoor unit, and routing electrical power supply. Be sure to

fill air spaces after installation is complete.

IMPORTANT: All refrigerant lines must be insulated

because the refrigerant flow device is located in the

outdoor section.

Run liquid and suction refrigerant piping.

1. Run pipes as directly as possible, avoiding any unnec

essary turns and bends.

2. Suspend refrigerant pipes so that the insulation is not dam

aged and vibrations are not transmitted to the

structure,

3. Leave slack in refrigerant pipe between the structure and

the indoor and outdoor sections to absorb vibration.

Step 6 — Make Piping Connections

NOTE: The outdoor section must be connected to the indoor

section using field-supplied tubing.

To make coimections:

1. Unpack factory-supplied tubing package. Unwind tubing

carefully. Do not bend or kink tubing.

10