A. warning – Carrier 48XL User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

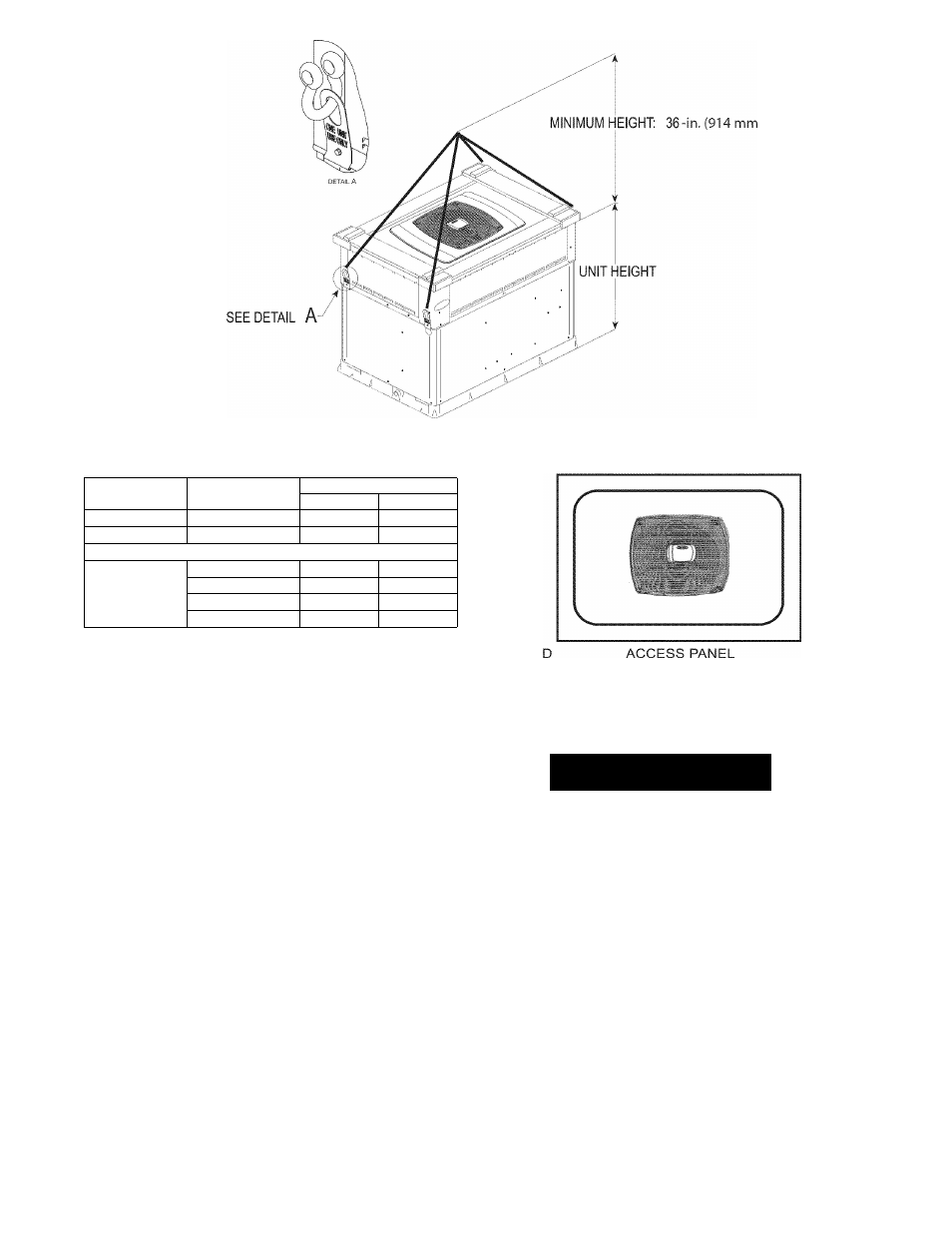

CABINET

MODEL

RIGGING WEIGHT

lb

kg

Small

48XL-024

420

191

Small

48XL-030

427

194

Large

48XL-036

515

234

48XL-042

537

244

48XL-048

543

246

48XL-060

594

269

NOTE: See dimensional drawing for corner weight distribution. Corner

weights shown on drawing are based on unit-only weights and do not

include packaging.

Fig. 7 - Suggested Rigging

IMPORTANT:

Use flexible connectors between ductwork and

unit to prevent transmission of vibration. Use suitable gaskets to

ensure weather tight and airtight seal. When electric heat is

installed, use fireproof canvas (or similar heat resistant material)

connector between ductwork and unit discharge connection. If

flexible duct is used, insert a sheet metal sleeve inside duct. Heat

resistant duct connector (or sheet metal sleeve) must extend 24-in.

(610 mm) from electric heater element.

3. Size ductwork for max possible air flow (See Table 1).

4. Seal, insulate, and weatherproof all external ductwork. Seal,

insulate and cover with a vapor barrier all ductwork passing

through conditioned spaces. Follow latest Sheet Metal and

Air

Conditioning

Contractors

National

Association

(SMACNA) and Air Conditioning Contractors Association

(ACCA) minimum installation standards for residential

heating and air conditioning systems.

3. Secure all ducts to building structure. Flash, weatherproof,

and vibration-isolate duct openings in wall or roof

according to good construction practices.

CONVERTING

HORIZONTAL

DISCHARGE

UNITS

TO

DOWNFLOW (VERTICAL) DISCHARGE UNITS

A. WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, always turn off main

power to system and tag. There may be more than one

disconnect switch. Turn off accessory heater power switch if

applicable.

NOTE: If

unit is not equipped with duct covers, accessory duct

covers are required. See pre-sale literature.

1. Open all electrical disconnects and install lockout tag before

starting any service work.

2. Remove side duct covers to access bottom return and

supply knockouts.

NOTE:

These panels are held in place with tabs similar to an

electrical knockout.

3. Use a screwdriver and hammer to remove the panels in the

bottom of the composite unit base.

4. Ensure the side duct covers are in place to block off the

horizontal air openings (See Fig. 8).