Table 1—physical data (con’t) - unit 48xl, Provide clearances, Important – Carrier 48XL User Manual

Page 7: Rig and place unit

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

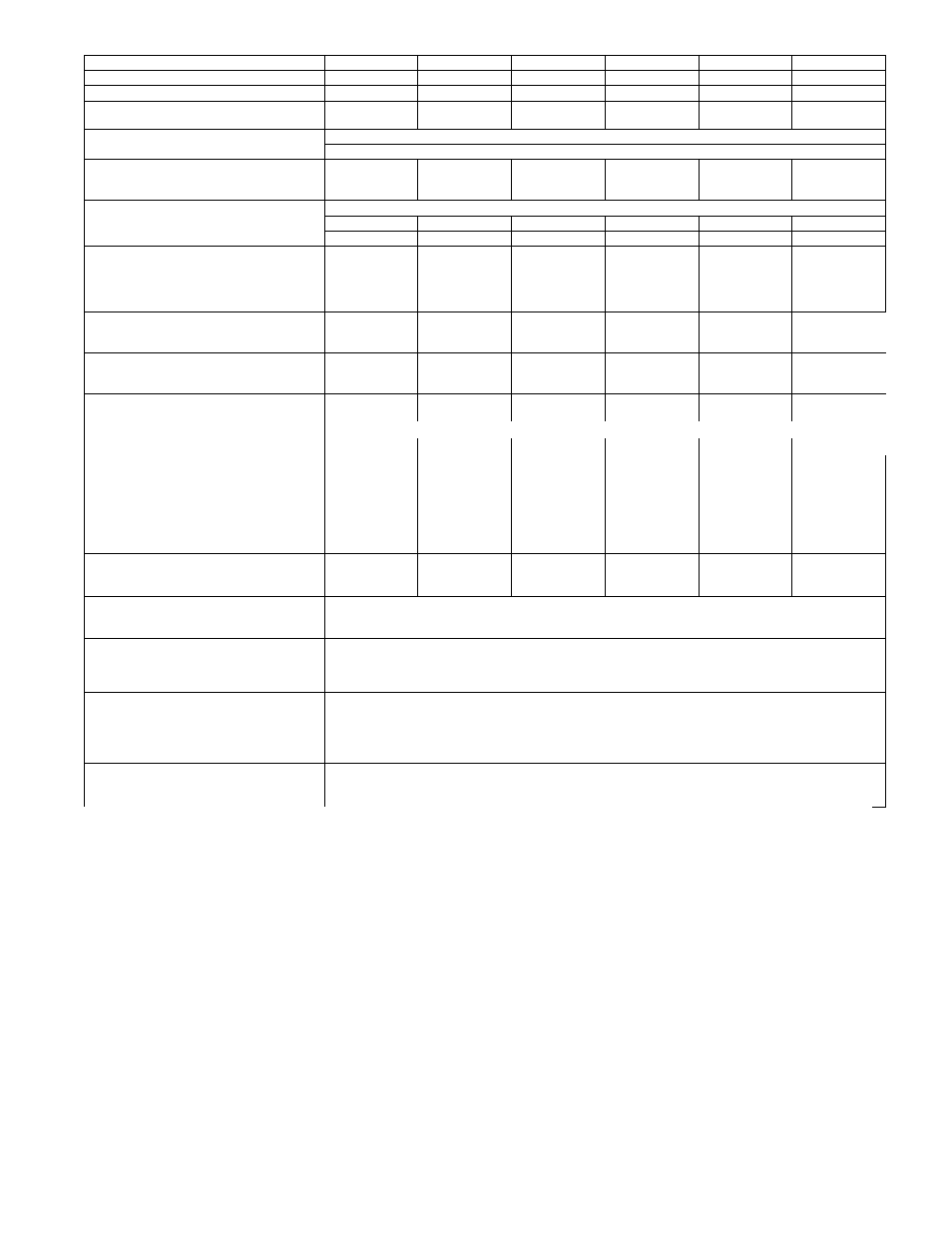

Table 1—Physical Data (Con’t) - Unit 48XL

UNIT SIZE

048090

048115

048130

060090

060115

060130

NOMINAL COOLING CAPACITY (ton)

4

4

4

5

5

5

NOMINAL HEATING CAPACITY (Btu)

90,000

115,000

130,000

90,000

115,000

130,000

OPERATING WEIGHT (lb)

521

521

521

572

572

572

(kg)

236

236

236

259

259

259

COMPRESSORS

2-Stage Scroll

Quantity

1

REFRIGERANT: PURON (R-410A)

Quantity (lb)

15.3

15.3

15.3

15.8

15.8

15.8

(kg)

6.9

6.9

6.9

7.2

7.2

7.2

REFRIGERANT METERING DEVICE

TXV

Size

4 Ton

4 Ton

4 Ton

5 Ton

5 Ton

5 Ton

Part Number

EA36YD149

EA36YD149

EA36YD149

EA36YD159

EA36YD159

EA36YD159

OUTDOOR FAN

Nominal Cfm

3300

3300

3300

3300

3300

3300

Diameter (in.)

22

22

22

22

22

22

(mm)

559

559

559

559

559

559

Motor Hp (Rpm)

1/4 (1100)

1/4 (1100)

1/4 (1100)

1/3 (1110)

1/3 (1110)

1/3 (1110)

OUTDOOR COIL

Rows...Fins/in.

2...21

2...21

2...21

2...21

2...21

2...21

Face Area (sq ft)

19.4

19.4

19.4

23.3

23.3

23.3

INDOOR COIL

Rows...Fins/in.

3...17

3...17

3...17

4...17

4...17

4...17

Face Area (sq ft)

5.7

5.7

5.7

5.7

5.7

5.7

INDOOR FAN

Nominal Airflow (Cfm)

Comfort

Variable based on Comfort Roll back (see User Interface instructions for more information).

Efficiency

1400

1400

1400

1750

1750

1750

Max

1600

1600

1600

2000

2000

2000

Furnace (gas ht.) airflow-Low Stage

815

1215

1255

845

1215

1255

Furnace (gas ht.) airflow-High Stage

1385

1885

1875

1300

1910

1920

Size (in.)

11x10

11x10

11x10

11x10

11x10

11x10

(mm)

279x254

279x254

279x254

279x254

279x254

279x254

Motor HP (RPM)

3/4

3/4

3/4

1

1

1

FURNACE SECTION*

Burner Orifice No. (Qty...Driii Size)

Natural Gas

3...3S

3...33

3...31

3...38

3...33

3...31

HIGH-PRESSURE SWITCH (psig)

Cut-out

670 ± 10

Reset (Auto)

470 ±25

HIGH-PRESSURE SWITCH 2 (psig)

(Compressor Solenoid)

Cut-out

565 ± 15

Reset (Auto)

455 ± 15

LOSS-OF-CHARGE /

LOW-PRESSURE SWITCH

(Liquid Line) (psig)

Cut-out

23 ±5

Reset (auto)

55 ±5

RETURN-AIR FILTERS Throwaway

(in.)t

24x36x1

(mm)

610x914x25

*Based on altitude of 0 to 2000 ft (0 to 610 m).

tRecommended filter sizes for field-installed air filter grilles mounted on the wall or ceiling of the conditioned structure. Required filter sizes shown are based on

the larger of the ARI (Air Conditioning and Refrigeration Institute) rated cooling airflow or the heating airflow velocity of 300 ft/minute for throwaway type or 450

ft/minute for high-capacity type. Air filter pressure drop for non-standard filters must not exceed 0.08 IN. W.C.

Provide Clearances

The required minimum service clearances are shown in 3 and 6.

Adequate ventilation and outdoor air must be provided. The

outdoor fan draws air through the outdoor coil and discharges it

through the top fan grille. Be sure that the fan discharge does not

recirculate to the outdoor coil. Do not locate the unit in either a

corner or under an overhead obstruction. The minimum clearance

under a partial overhang (such as a normal house overhang) is 48

in, above the unit top. The maximum horizontal extension of a

partial overhang must not exceed 48 in, (12f9 mm).

IMPORTANT:

Do not restrict outdoor airflow. An air restriction

at either the outdoor-air inlet or the fan discharge may be

detrimental to compressor life.

Do not place the unit where water, ice, or snow from an overhang

or roof will damage or flood the unit. Do not install the unit on

carpeting or other combustible materials. Slab-mounted units

should be at least 4 in, (102 mm) above the highest expected water

and runoff levels. Do not use unit if it has been under water.

Rig and Place Unit

Rigging and handling of this equipment can be hazardous for

many reasons due to the installation location (roofs, elevated

structures, etc.).

Only trained, qualified crane operators and ground support staff

should handle and install this equipment.

When working with this equipment, observe precautions in the

literature, on tags, stickers, and labels attached to the equipment,

and any other safety precautions that might apply.

Training for operators of the lifting equipment should include, but

not be limited to, the following:

1, Application of the lifter to the load, and adjustment of the

lifts to adapt to various sizes or kinds of loads.

2, Instruction in any special operation or precaution,

3, Condition of the load as it relates to operation of the lifting

kit, such as balance, temperature, etc.

Follow all applicable safety codes. Wear safety shoes and work

gloves,

7