Warning – Carrier 48XL User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

3, Secure flue hood to flue panel by inserting a single screw on

the top and the bottom of the hood,

r (25

mm)

MiN.

Return Duct Cover

Supply Duct Cover

Fig. 8 - 48XL with Duct Covers On

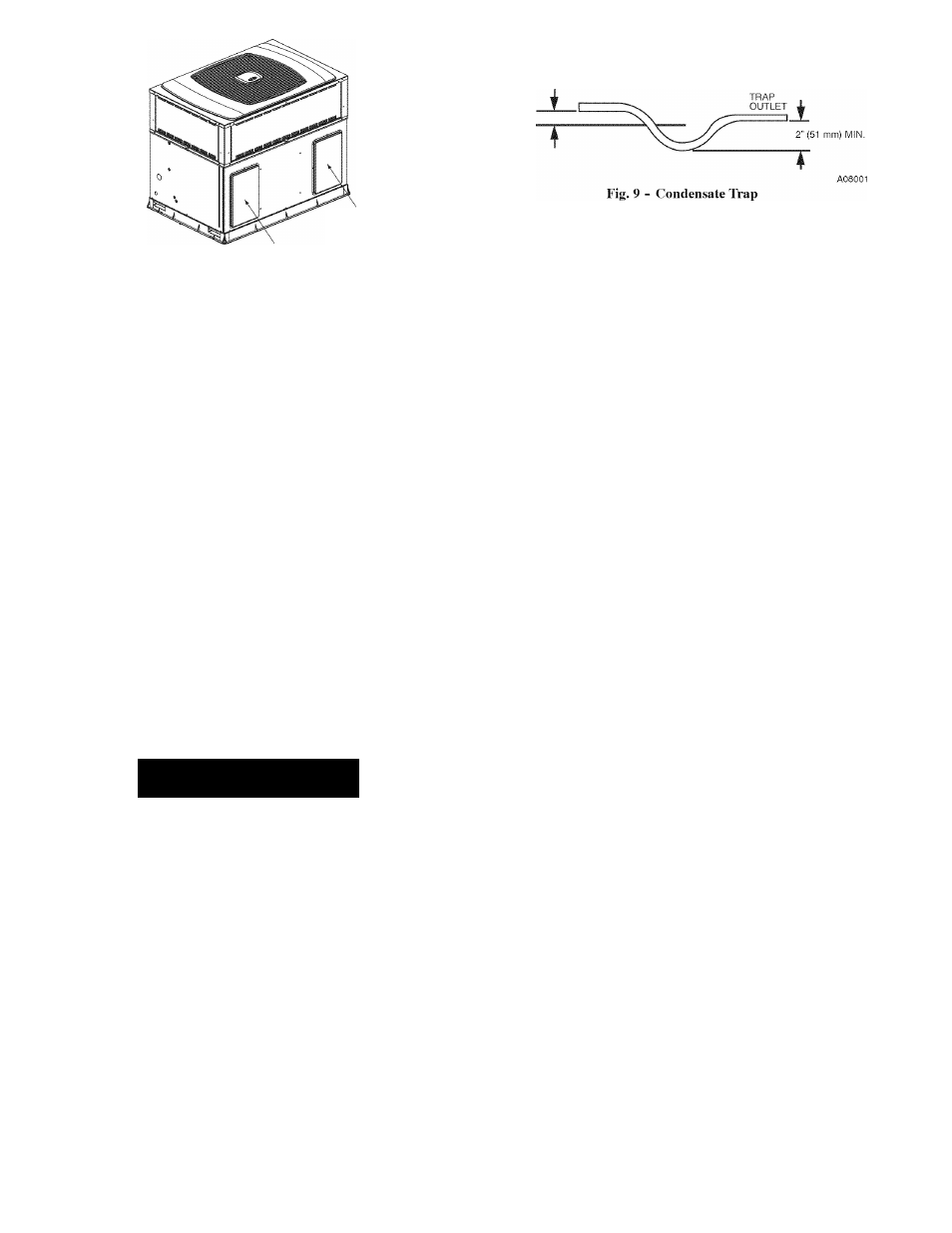

Provide for Condensate Disposal

NOTE:

Ensure that condensate-water disposal methods comply

with local codes, restrictions, and practices.

The units dispose of condensate through a 3/4 -in. NPT female

fitting that exits on the compressor end of the unit. Condensate

water can be drained directly onto the roof in rooftop installations

(where permitted) or onto a gravel apron in ground level

installations. Install a field-supplied condensate trap at end of

condensate connection to ensure proper drainage. Make sure that

the outlet of the trap is at least f in, (23 mm) lower than the

drain-pan

condensate connection to prevent the

pan from

overflowing. Prime the trap with water. When using a gravel apron,

make sure it slopes away from the unit.

If the installation requires draining the condensate water away from

the unit, install a field-supplied 2-in. (3f mm) trap at the

condensate connection to ensure proper drainage. Condensate trap

is available as an accessory or is field-supplied. Make sure that the

outlet of the trap is at least f in, (23 mm) lower than the unit

drain-pan

condensate connection to prevent the

pan from

overflowing. Connect a drain trough using a minimum of

field-supplied 3/4 -in. PVC or field-supplied 3/4 -in. copper pipe

at outlet end of the 2 -in. (3f mm) trap (See Fig. 9). Do not

undersize the tube. Pitch the drain trough downward at a slope of at

least f in, for every fO ft. (3 m) of horizontal run. Be sure to check

the drain trough for leaks. Prime the trap at the beginning of the

cooling season start-up.

Install Flue Hood

^ WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

injury or death.

The venting system is designed to ensure proper venting.

The flue hood assembly must be installed as indicated in

this section of the unit installation instructions.

Install the flue hood as follows:

f. This installation must conform with local building codes

and with the National Fuel Gas Code (NFGC), NFPA

34/ANSI Z223.f (in Canada, CAN/CSA Bf49.f, and

Bf49.2) or latest revision. Refer to provincial and local

plumbing or wastewater codes and other applicable local

codes,

2, Remove flue hood from shipping location (inside the return

section of the blower compartment-See Fig. 8). Remove the

return duct cover to locate the flue hood. Remove two

screws on flue panel. Place flue hood assembly over flue

panel. Orient screw holes in flue hood with holes in the flue

panel.

Install Gas Piping

The gas supply pipe enters the unit through the access hole

provided. The gas connection to the unit is made to the f/2-in,

FPT gas inlet on the gas valve.

Install a gas supply line that runs to the heating section. Refer to

Table 2 and the current edition of NFGC in the U.S, and the current

NSCNGPIC in Canada. Do not use cast-iron pipe. It is

recommended that a black iron pipe is used. Check the local utility

for recommendations concerning existing lines. Size gas supply

piping for 0.3 IN. W.C, maximum pressure drop. Never use pipe

smaller than the f/2-in. FPT gas inlet on the unit gas valve.

For natural gas applications, the gas pressure at unit gas connection

must not be less than 4,0 IN, W.C, or greater than 13 IN, W.C,

while the unit is operating. For propane applications, refer to

propane conversion kit instructions.

A 1/8-in, NPT plugged tapping, accessible for test gauge

connection, must be installed immediately upstream of the gas

supply connection to the gas valve and downstream of manual

equipment shutoff valve.

When installing the gas supply line, observe local codes pertaining

to gas pipe installations. Refer to the NFPA 34/ANSI Z223,1-2006

(in Canada, CAN/CSA B149.1).

NOTE: In the state of Massachusetts:

1, Gas supply connections MUST be performed by a licensed

plumber or gas fitter.

2, When flexible connectors are used, the maximum length

shall not exceed 36 in. (913 mm).

3, When lever handle type manual equipment shutoff valves

are used, they shall be T-handle valves.

4, The use of copper tubing for gas piping is NOT approved

by the state of Massachusetts,

In the absence of local building codes, adhere to the following

pertinent recommendations:

1, Avoid low spots in long runs of pipe. Grade all pipe 1/4 in,

(6.33 mm) for every 13 ft (4,6 m) of length to prevent traps.

Grade all horizontal runs downward to risers. Use risers to

connect to heating section and to meter.

2, Protect all segments of piping system against physical and

thermal damage. Support all piping with appropriate straps,

hangers, etc. Use a minimum of one hanger every 6 ft. (1,8

m).

For

pipe

sizes

larger

than

1/2

in,,

follow

recommendations of national codes,

3, Apply joint compound (pipe dope) sparingly and only to

male threads of joint when making pipe connections. Use

only pipe dope that is resistant to action of liquefied

petroleum gases as specified by local and/or national codes.

Never use Teflon tape,

4, Install sediment trap in riser leading to heating section (See

Fig. 10). This drip leg functions as a trap for dirt and

condensate,

3, Install an accessible, external, manual main shutoff valve in

gas supply pipe within 6 ft (1,8 m) of heating section.

6, Install ground-joint union close to heating section between

unit manual shutoff and external manual main shut off

valve.

10