Table 6 - heating inputs, Table 7 - ecm wet coil pressure drop (in. w.c.), Table 8 - filter pressure drop table (in. w.c.) – Carrier 48XL User Manual

Page 26: Important

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

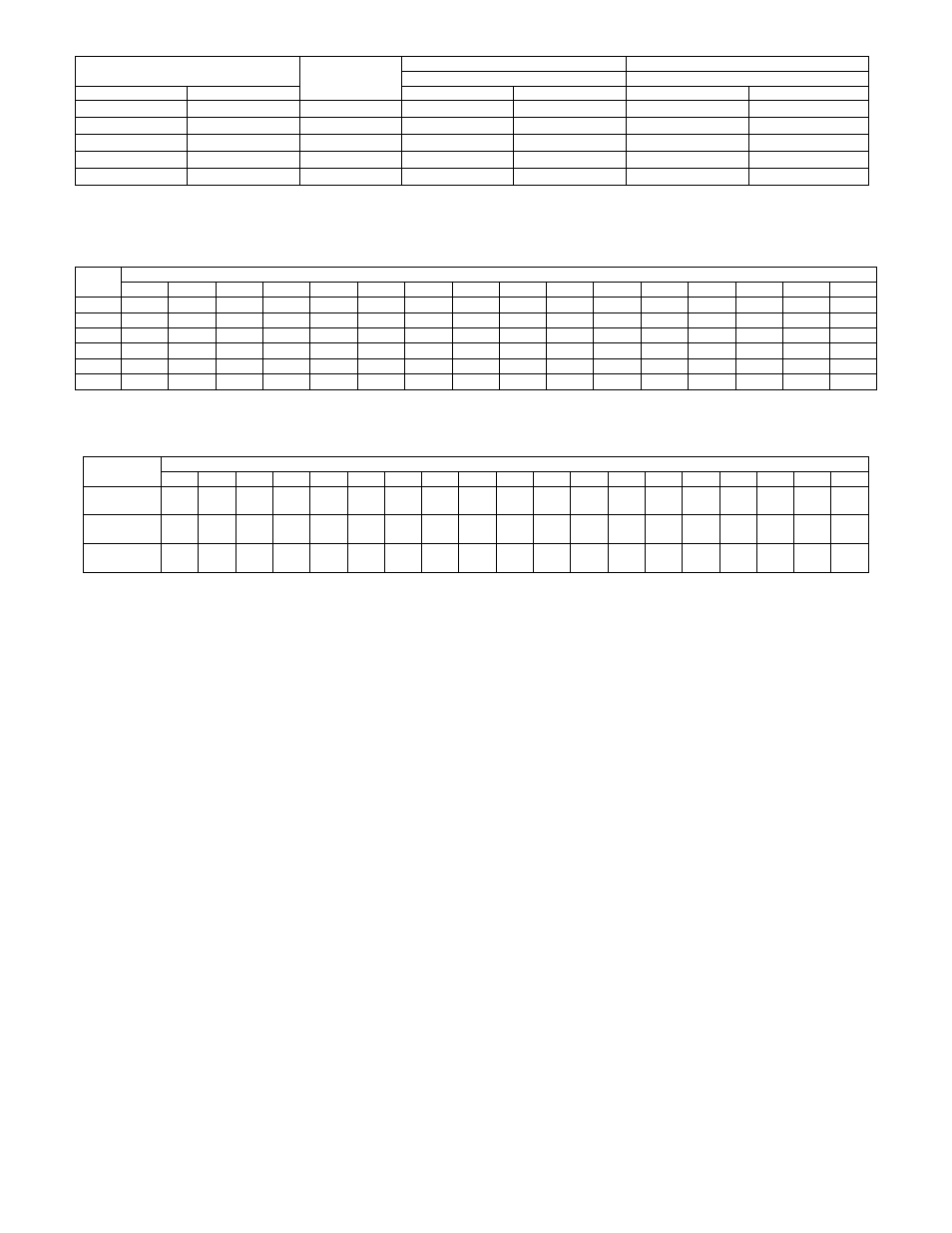

Table 6 - Heating Inputs

HEATING INPUT (BTU/HR)*

NUMBER OF

ORIFICES

GAS SUPPLY PRESSURE (IN. W.C.)

MANIFOLD PRESSURE (IN. W.C.)

Natural

Natural

High Stage

Low Stage

Min

Max

High Stage

Low Stage

40,000

26,000

2

4.0

13.0

3.2~3.8

1.4 ~ 2.0

60,000

39,000

3

4.0

13.0

3.2~3.8

1.4 ~ 2.0

90,000

58,500

3

4.0

13.0

3.2~3.8

1.4 ~ 2.0

115,000

75,000

3

4.0

13.0

3.2~3.8

1.4 ~ 2.0

130,000

84,500

3

4.0

13.0

3.2~3.8

1.4 ~ 2.0

*Cubio ft of natural gas per hour for gas pressures of .5 psig (14 IN. W.C.) or less and a pressure drop of .5 IN. W.C. (based on a .60 specific gravity gas). Ref:

Table 6.2 (b) NPFA54/ANSI Z223.1.

Table 7 - ECM Wet Coil Pressure Drop (IN. W.C.)

UNIT

SIZE

STANDARD CFM (SCFM)

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2100

024

0.005

0.007

0.010

0.012

0.015

-

-

-

-

-

-

-

-

-

-

-

030

-

0.007

0.010

0.012

0.015

0.018

0.021

0.024

-

-

-

-

-

-

-

-

036

-

-

-

0.019

0.023

0.027

0.032

0.037

0.042

0.047

-

-

-

-

-

-

042

-

-

-

-

0.014

0.017

0.020

0.024

0.027

0.031

0.035

0.039

0.043

-

-

-

048

-

-

-

-

-

-

0.027

0.032

0.036

0.041

0.046

0.052

0.057

0.063

0.068

-

060

-

-

-

-

-

-

-

-

-

0.029

0.032

0.036

0.040

0.045

0.049

0.053

Table 8 - Filter Pressure Drop Table (IN. W.C.)

FILTER SIZE

in. (mm)

CFM

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2100

2200

2300

20X20X1

(508x508x25)

0.05

0.07

0.08

0.1

0.12

0.13

0.14

0.15

24X30X1

(610x762x25)

—

—

—

—

0.05

0.6

0.07

0.07

0.08

0.09

0.1

24X36X1

(610x914x25)

—

—

—

—

—

—

—

0.06

0.07

0.07

0.08

0.09

0.09

0.10

0.11

0.12

0.13

0.14

0.14

IMPORTANT:

When evaluating the refrigerant charge, an

indicated adjustment to the specified factory charge must always be

very minimal. If a substantial adjustment is indicated, an abnormal

condition exists somewhere in the cooling system, such as

insufficient airflow across either coil or both coils,

REFRIGERANT CHARGE

The amount of refrigerant charge is listed on the unit rating plate

and/or the physical data table. Refer to the Refrigeration Service

Techniques Manual, Refrigerants Section,

NO CHARGE

Check for leak. Use standard evacuating techniques. After

evacuating system, weigh in the specified amount of refrigerant

(refer to system rating plate).

LOW CHARGE COOLING

Use Cooling Charging Chart (Fig. 23). Vary refrigerant until the

conditions of the chart are met. Note that charging charts are

different from type normally used. Charts are based on charging

the units to correct subcooling for the various operating conditions.

Accurate pressure gauge and temperature sensing devices are

required. Connect the pressure gauge to the service port on the

suction line. Mount the temperature sensing device on the suction

line and insulate it so that the outdoor ambient does not affect the

reading. Indoor air CFM must be within the normal operating

range of the unit.

TO USE COOLING CHARGING CHARTS

Take the liquid line temperature and read the manifold pressure

gauges.

Refer to the chart to determine what the liquid line temperature

should be,

NOTE:

If the problem causing the inaccurate readings is a

refrigerant leak, refer to Check for Refrigerant Leaks section.

NON-COMMUNICATING

EMERGENCY

COOLING

/

HEATING MODE: 4-WIRE THERMOSTAT

This mode of operation is provided only in the case where the UI

has failed or is otherwise unavailable. If communications cannot be

established with the UI, the Infinity furnace board will enable the

standard thermostat input terminals to allow simple thermostatic

control of the 48XL unit.

For control with a standard thermostat, disconnect the ABCD

connectors from both control boards and using No. 18 AWG

color-coded, insulated type 90°C minimum or equivalent wire,

make the connections between the standard thermostat, the furnace

board, and the HP/AC board per Fig. 22, Recommend the use of

interconnecting wire with 103C, 600V, 2/64” insulation.

The Infinity control will respond to cooling and heating demands

with the maximum safe airflow based on gas furnace output and

unit cooling capacity.

26