Final checks, Care and maintenance – Carrier 48XL User Manual

Page 32

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A91431

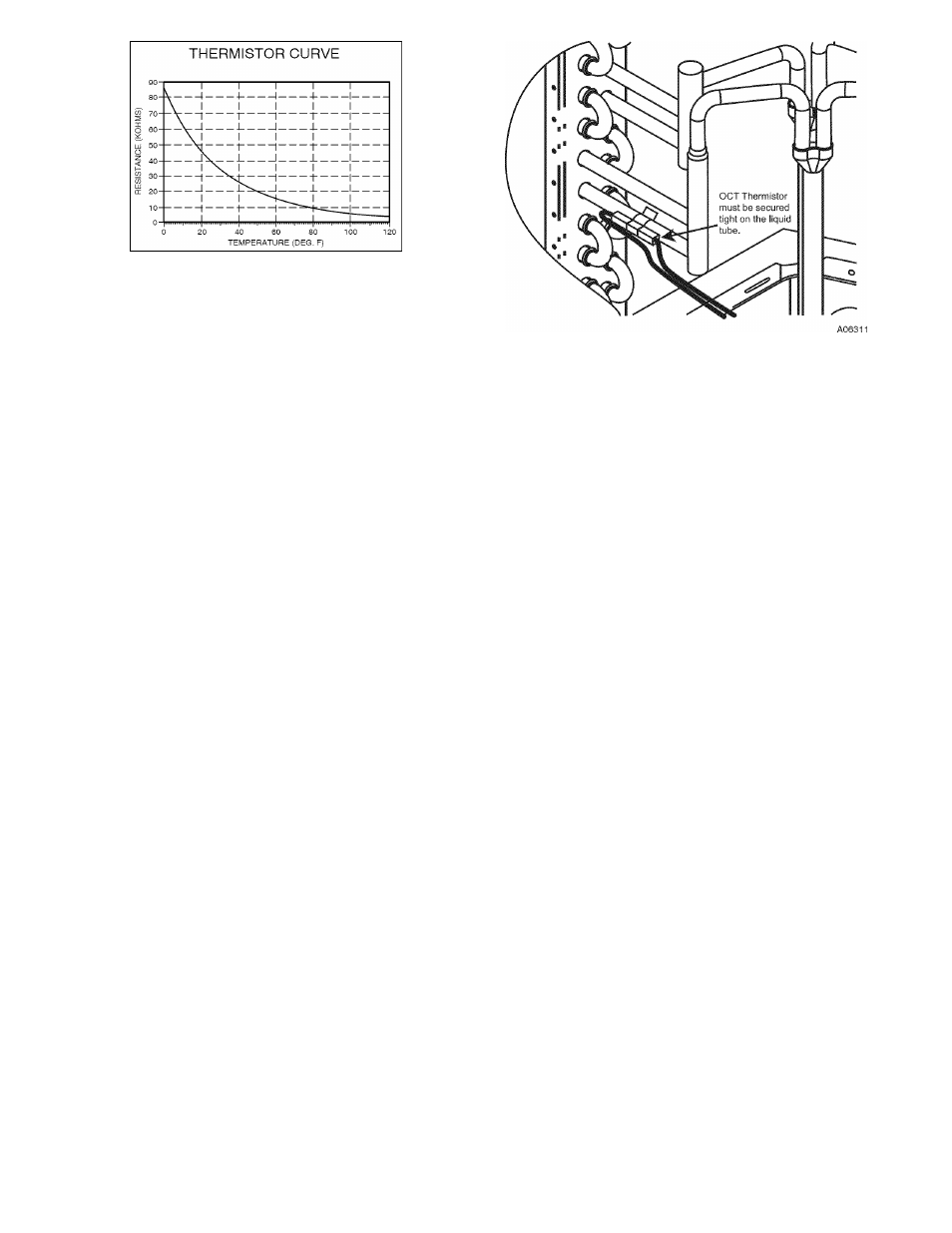

Fig. 25 - Resistance Values Versus Temperature

THERMISTOR SENSOR COMPARISON

The control continuously monitors and compares the outdoor air

temperature sensor and outdoor coil temperature sensor to ensure

proper operating conditions. The comparison is:

• In cooling mode, if the outdoor air sensor indicates > 10 °F

(-12°C) warmer than the coil sensor (or) the outdoor air sensor

indicates > 20°F cooler than the coil sensor, the sensors are out of

range.

• In heating if the outdoor air sensor indicates > 33°F (2°C)

warmer than the coil sensor (or) the outdoor air sensor indicates

> 10°F (-12°C) cooler than the coil sensor, the sensors are out

of range.

If the sensors are out of range, the control will flash the appropriate

fault code as shown in Table 3.

The thermistor comparison is not performed during low ambient

cooling operation.

FAILED THERMISTOR DEFAULT OPERATION

Factory defaults have been provided in the event of failure of

outdoor air thermistor and/or coil thermistor.

If the OAT sensor should fail, low ambient cooling will not be

allowed and the one-minute outdoor fan off delay will not occur.

Defrost will be initiated based on coil temperature and time.

If the OCT sensor should fail, low ambient cooling will not be

allowed. Defrost will occur at each time interval during heating

operation, but will terminate after 3 minutes.

If there is a thermistor out of range error, defrost will occur at each

time interval during heating operation, but will terminate after 3

minutes.

Refer to the Troubleshooting Chart (Table 10) for additional

troubleshooting information.

Fig. 26 - Outdoor Coil Thermistor (OCT) Attachment

FINAL CHECKS

IMPORTANT:

Before leaving job, be sure to do the following:

1. Ensure that all wiring is routed away from tubing and sheet

metal edges to prevent rub-through or wire pinching.

2. Ensure that all wiring and tubing is secure in unit before

adding panels and covers. Securely fasten all panels and

covers.

3. Tighten service valve stem caps to 1/2-turn past finger

tight.

4. Leave Users Manual with owner. Explain system operation

and periodic maintenance requirements outlined in manual.

3. Fill out Start-Up Checklist located at the back of this

manual and place in customer file.

CARE AND MAINTENANCE

For continuing high performance and to minimize possible

equipment failure, periodic maintenance must be performed on this

equipment.

Frequency of maintenance may vary depending upon geographic

areas, such as coastal applications. See Users Manual for

information.

32