Fig. 23 - cooling charging table-subcooling – Carrier 48XL User Manual

Page 27

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

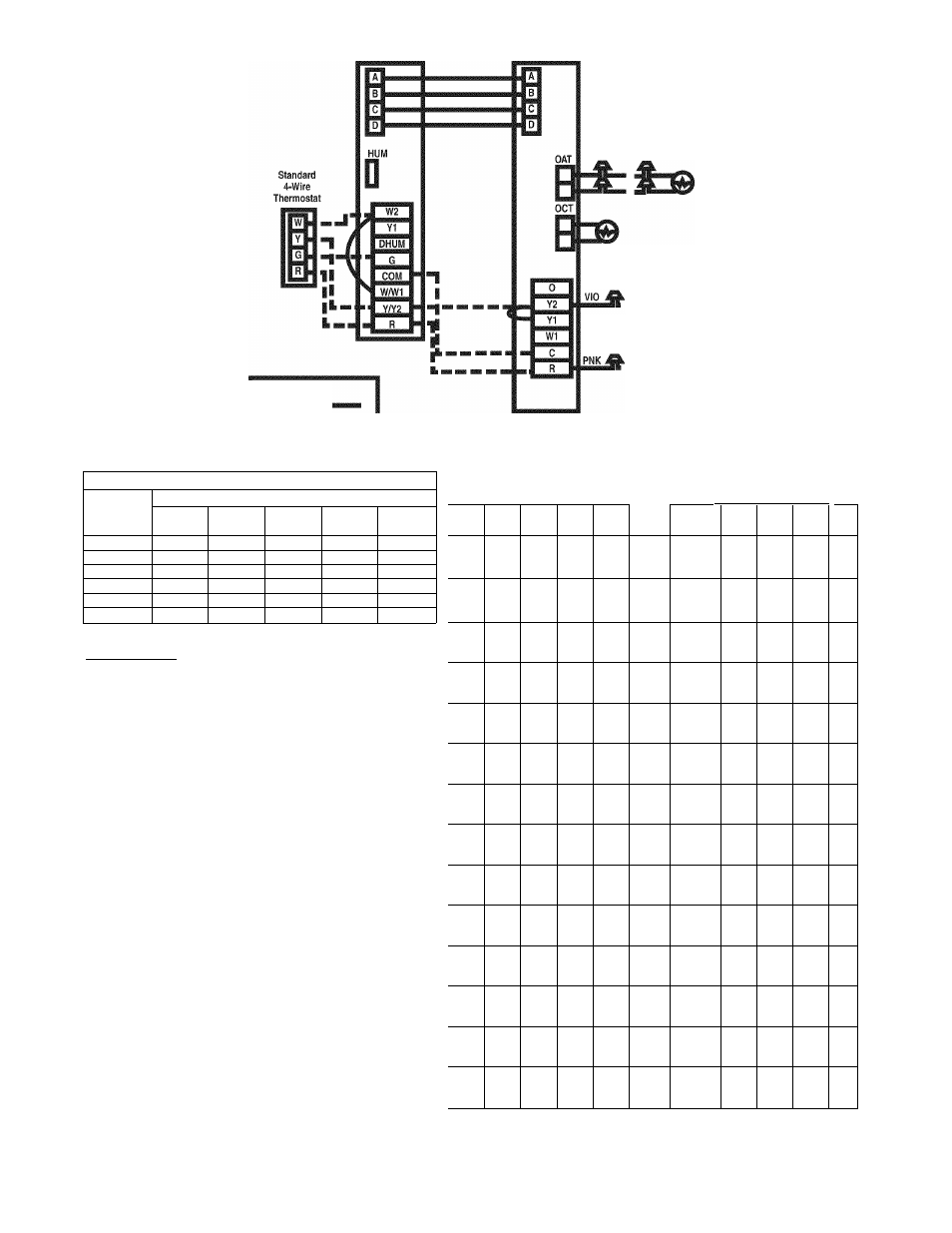

Infinity Furnace

Board

Infinity HP/AC

Board

Outdoor Air Thermistor

(Supplied with lU)

FIELD CONNECTION

REQUIRED

(BLACK WIRES)

Outdoor Coil Thermistor

FACTORY CONNECTED

FACTORY WIRES PROVIDED

FOR FIELD CONNECTION

OF

UTILITY CURTAILMENT

LEGEND

Jumped Wires i

Field Wiring

Fig. 22 - Noii-Coniniuiiicating Emergency Cooling/Heating Wiring Connections

Required Subcooling

°F (°C)

Model Size

Outdoor Ambient Temperature

75(24)

82 (28)

85(29)

95(35)

105(41)

024

15.5(8.6)

15.6(8.7)

15.7(8.7)

15.8(8.8)

15.9(8.9)

030

16,8 {9.3 )

16.4(9.1 )

16.2(9)

15.6(8.7)

15(8.3)

036

14(7.7)

13.9(7.7)

13.9(7.7)

13.8(7.7)

13.7(7.6)

042

19.2(10.7)

19.1 (10.6)

19.1(10.6)

18.9(10.5)

18.7(10.4)

048

21(11,6)

20,8(11,5)

20,7(11.5)

20.4(11.3)

20.2(11.2)

060

16.2(9)

16.6(9.2)

16.8(9.3)

17.3(9.6)

17.8(9.9)

Required Liquid Line Temperature for a Specific Subcooling (R410A)

Required Subcooling

(°F)

ressure

ipsig)

5

10

15

25

Pressure

(kPa)

3

6

8

14

174

56

51

46

36

1200

13

11

8

2

181

59

54

49

39

1248

15

12

9

4

188

61

56

51

41

1296

16

13

10

5

195

63

58

53

43

1344

17

14

12

6

202

65

60

55

45

1393

18

16

13

7

209

67

62

57

47

1441

20

17

14

9

216

69

64

59

49

1489

21

18

15

10

223

71

66

61

51

1537

22

19

16

11

230

73

68

63

53

1586

23

20

17

12

237

75

70

65

55

1634

24

21

19

13

244

77

72

67

57

1682

25

22

20

14

251

79

74

69

59

1730

26

23

21

15

259

81

76

71

61

1786

27

24

22

16

267

83

78

73

63

1841

28

26

23

17

275

85

80

75

65

1896

29

27

24

18

283

87

82

77

67

1951

31

28

25

19

291

89

84

79

69

2006

32

29

26

20

299

91

86

81

71

2061

33

30

27

22

308

93

88

83

73

2123

34

31

28

23

317

95

90

85

75

2185

35

32

29

24

326

97

92

87

77

2247

36

33

30

25

335

99

94

89

79

2309

37

34

31

26

344

101

96

91

81

2372

38

35

33

27

353

102

97

92

82

2434

39

36

34

28

363

104

99

94

84

2503

40

37

35

29

373

106

101

96

86

2571

41

39

36

30

383

108

103

98

88

2640

42

40

37

31

393

110

105

100

90

2709

43

41

38

32

403

112

107

102

92

2778

44

42

39

33

413

114

109

104

94

2847

45

43

40

34

423

116

111

106

96

2916

46

44

41

35

433

117

112

107

97

2985

47

45

42

36

443

119

114

109

99

3054

48

46

43

37

453

121

116

111

101

3123

49

47

44

38

463

122

117

112

102

3192

50

47

45

39

473

124

119

114

104

3261

51

48

46

40

483

126

121

116

106

3330

52

49

47

41

493

127

122

117

107

3399

53

50

47

42

503

129

124

119

109

3468

54

51

48

43

513

130

125

120

110

3537

55

52

49

44

523

132

127

122

112

3606

56

53

50

44

533

133

128

123

113

3675

56

54

51

45

Required Subcooling (°C)

Charging Procedure

1- Measure Discharge line pressure by attaching a gauge to the service port.

2- Measure the Liquid line temperature by attaching a temperature sensing device to it.

3- Insulate the temperature sensing device so that the Outdoor Ambient doesn’t affect

the reading,

4- Refer to the required Subcooling in the table based on the model size and the

Outdoor Ambient temperature.

5- Interpolate if the Outdoor temperature lies in between the table values. Extrapolate if

the temperature lies beyond the table range.

6- Find the Pressure Value corresponding to the the measured Pressure on the

Compressor Discharge line.

7- Read across from the Pressure reading to obtain the Liquid line temperature for a

required Subcooling.

8- Add Charge if the measured temperature is higher than the liquid line temperature

value in the table.

9- Add Charge using the service connection on the Suction line of the Compressor.

50DU500166-2.0

A08423

Fig. 23 - Cooling Charging Table-Subcooling

27