Unit protection, Pumpdown procedure, Compressor service – Carrier 38SE User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 8 — Chargemaster® Charging Chart

(38SE Capillary Tube or AccuRater^'^ Systems)

OUTDOOR

TEMP (F)

EVAPORATOR TEMP (F)

32| 34136

38 40 42 im 46 |48 50 52

54

Suction Line Temperature (F)

60

60

— -

65

4%

58

65

70

41

48

58

68

70

m

75

35

41

48

58

68

—

80

31

36 .42

50

59.

69^

"To”

'

!-------

w.

44

40

w

47

53 j 61

82

■■¿9'78“

—

95

42

48 53

59

67

79

100

43 I 47

52

58

68 88

105

I 44

48

53

60

75

104

no

49

54

65

80

115

--

50

62

69

Example

UNIT PROTECTION

High-Pressure Relief Valve

is located in compressor when so

equipped. Relief valve opens at a pressure differential of

approximately 450 — 550 psi between suction and discharge.

Valve permits pressure equalization at running condition

described above and during unit shutdown. A hissing sound

during pressure equalization does not indicate bad valves.

High Pressurestat

is located on unit liquid line. High

pressurestat settings are; cutout, 425 ± 5 psig; cut-in, 320 ±

20 psig.

Low Pressurestat

is located on unit suction line. Low

pressurestat settings are; cutout, 31 ± 4 psig, cut-in, 60

(+15,-0) psig.

Internal Temperature And/Or Current Sensitive Overloads

reset automatically when internal motor temperatures drop

to a safe level (overload may require up to 30 minutes to

reset). When internal overload is suspected of being open,

check by using an ohmmeter or continuity tester. If

necessary, refer to Carrier Standard Service Techniques

Manual, Chapter 2, for complete instructions.

Outdoor Fan Thermostat

(38SE055 and 38GR units)

switches fan to high speed (Table 5) when outdoor

temperature reaches 90 F — maintains proper condensing

temperature at high outdoor air temperatures. Thermostat

is located on Control Panel, Fig. 7.

Filter-Drier

is installed in liquid line.

FAN THERMOSTAT

«F SO EQUIPPED)

CONTROL

TRANSFORMER

(DUAL SECONDARY)

'CS

CEPTACLE

ITROL RELAY

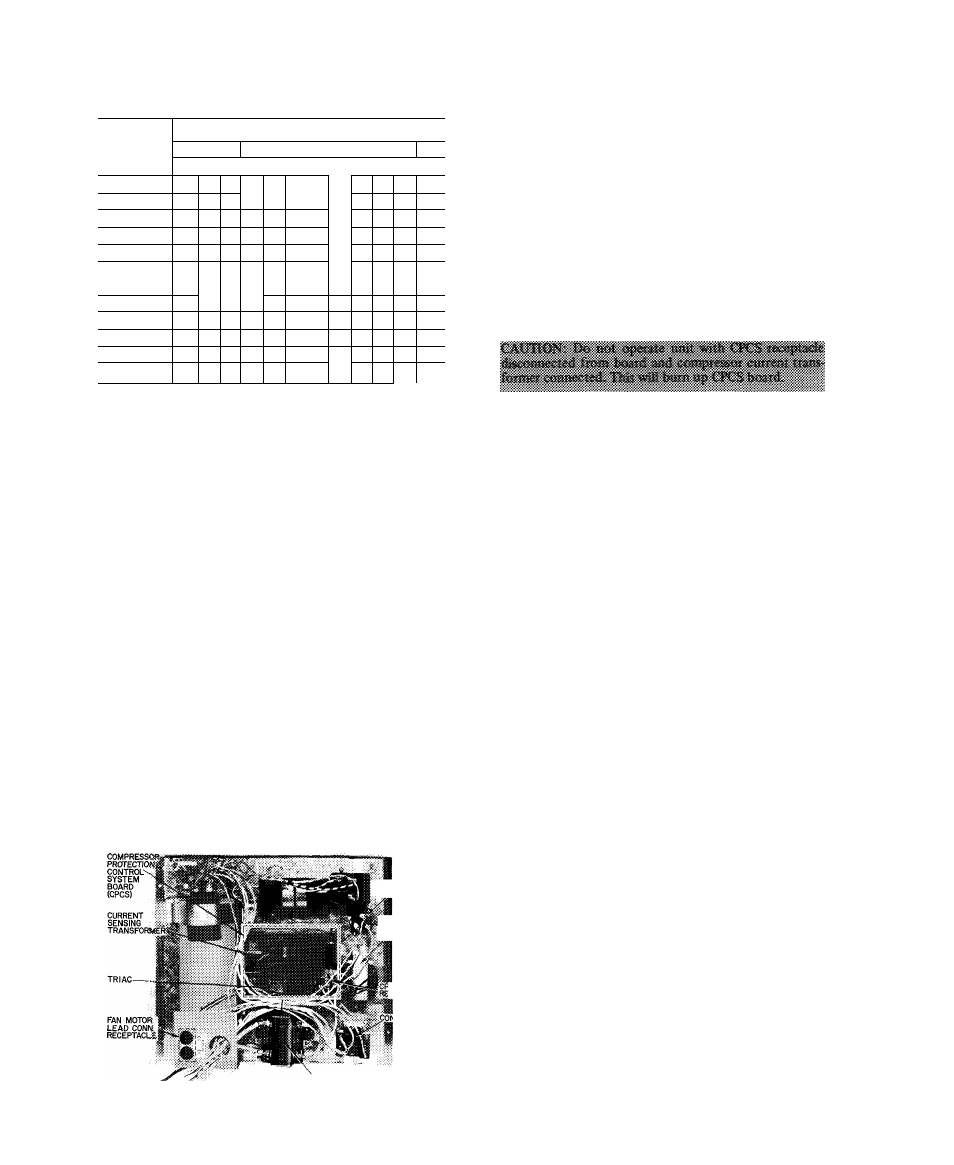

Compressor Protection Control System

(CPCS — Solid

State, Fig. 7) provides; compressor motor locked rotor

protection; compressor start winding protection; compres

sor motor running overload protection; compressor over

temperature protection; contactor anti-chatter protection.

The CPCS also provides for a 4- to 6-minute delay before

restarting compressor after shutdown for any reason. If

compressor loading was light at the moment compressor

was shut off, the delay will be approximately 4 minutes. If

loading was heavy, the delay will be approximately 6

minutes. The CPCS board is located on control panel

beneath a sheet metal protective cover. To troubleshoot the

CPCS, remove protective sheet metal cover, and use unit

label diagram or wiring booklet with Control Circuit

Troubleshooting Chart, page 9.

TROUBLESHOOTING CHART NOTES (Page 9);

1. Ensure thermostat calls for cooling before troubleshoor-

ing unit.

2. To disconnect plug from receptacle on CPCS board —

press in tabs located on the receptacle and pull plug

gently while holding tabs. Do not pull on wiring.

3. When performing troubleshooting checks, CPCS recep

tacle must be plugged into CPCS board,

4. Receptacle female connections, which do not grip the

male pin tightly, may be repaired with a small pen knife.

5. When taking meter readings at CPCS receptacle, bottom

meter probe into terminal hole to ensure good electrical

contact.

6. Replace CPCS board if electrical short circuit causes

compressor failure. An electrical short in compressor can

short the triac (electronic switch located on CPCS

board). Triac may fail in a closed (conducting) position

and not open the control circuit.

PUMPDOWN PROCEDURE

The 38GR,SE units may be pumped down in order to

make repairs on low side of system without losing complete

refrigerant charge.

1. Attach pressure gage to suction service valve gage port.

2. Frontseat the liquid line valve.

3. Jumper low-pressure switch.

4. Start unit and run until suction pressure reaches 5 psig

(see Caution).

5. Shut unit off and frontseat suction valve.

6. Vent remaining pressure to atmosphere.

CACTfC^' Thtf 58GR

«fill -idd c»nly

suppii&l

af

msv icaus« tiKtts 1« syde op

pre^pf-

stsi

by & djsdtejfgi pfissiiro a

sudifpti rtp? i>i AtOicin"

fessfore stis.'ifoi!

reiscte ? ppit, ff sha «¿rctifa, abKi urti! >4i

fipataeat awtsstsi 'tslve vpiit

fc-

CONTACTOR

Fig. 7 — Control Panel (Cover Removed)

COMPRESSOR SERVICE

Unit Single-Phase Compressors

of the split capacitor (PSC)

type require an equalized system pressure to start. When

supply voltage is within 10% limit and compressor does not

start, give compressor a temporary capacitance boost. See

f

V-