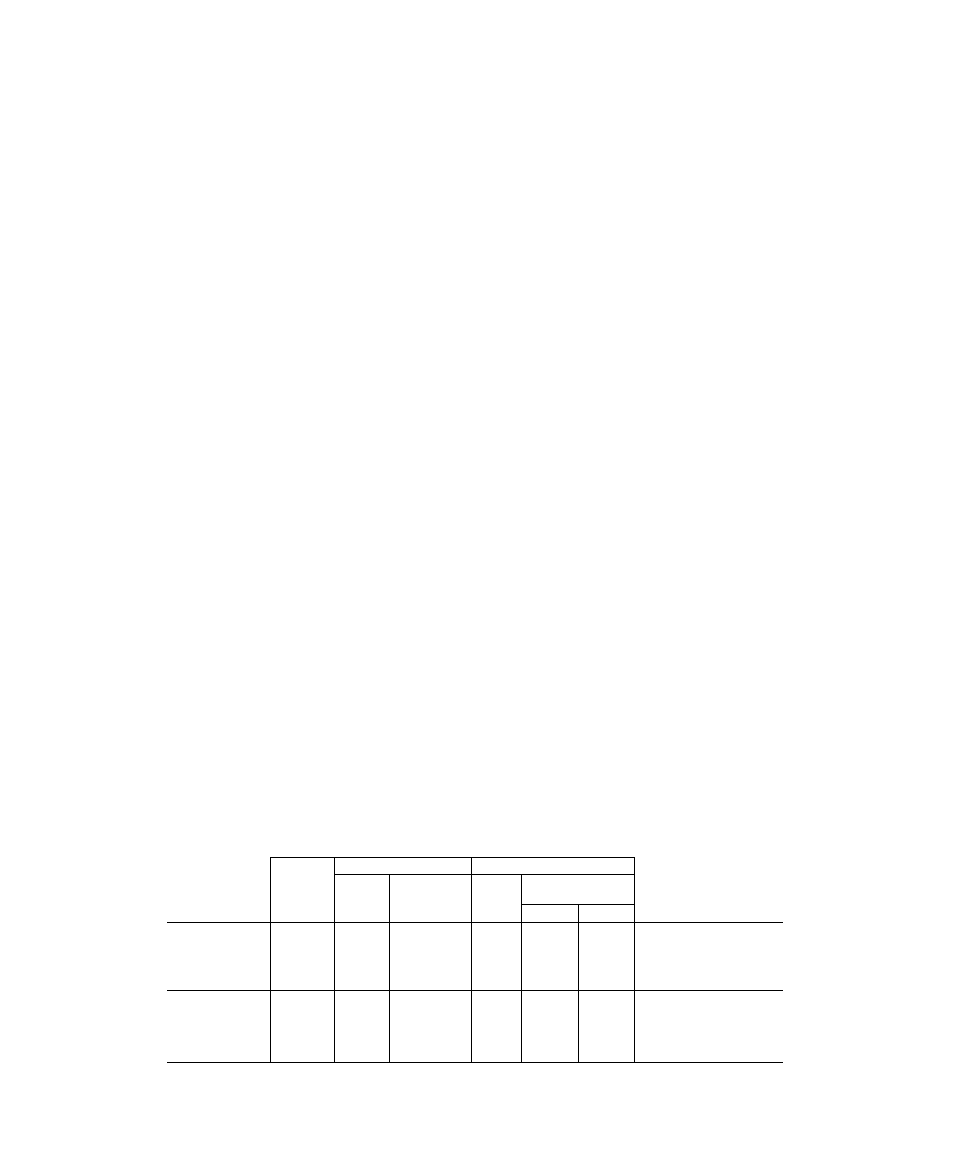

Table 2 — accessories, Part no, Hh07at070 – Carrier 38SE User Manual

Page 2: Description, 32lt900301, 38gb900021, Unit, 38se002,003, 38gr002,003,004,045, 38se004

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

tubing not available for 38GR006.) See Table 2 for

accessory tubing sizes and Table 3 for recommended

field-supplied tubing sizes. (Where evaporator is 20 ft or

more below condensing unit, reduce liquid line size one

diameter — min 1/4-in. OD.)

A capacity reduction results if accessory tubing is used

in 38SE004,045,055 systems. For example, when a 25 ft

accessory tubing package is used, there is a capacity

reduction of 2 1/2% on 38SE004, 3 3/4% on 38SE045 and

5% on 38SE055 systems. For maximum capacity from

these systems, use tubing sizes shown in Table 3.

Connection Recommendations

— Do not use damaged or

contaminated tubing. Do not use less than 10 ft of liquid

line. Do not cut 5/16-in or 1/4-in. liquid line. Bend or coil

to fit.

If accessory tubing package or evaporator section has

been open for more than 15 seconds per connection,

evacuate or purge evaporator coil and tubing system (use

field-supplied refrigerant, not unit refrigerant) Always

evacuate or purge if field-supplied tubing is used.

When making piping connections, be sure to provide

clearance at unit for electrical connections.

Connect

refrigerant liquid and suction lines to condensing

unit (Fig 1). Unit compatible fittings permit mechanical

(quick-connect) or sweat connections.

38GR005,006;

38SE004.045.055

Units

-

When

using

1 1/8-in. field-supplied siictlSff'line, remove suction line

adapter taped to compressor suction line. Connect 3/4-in.

end of adapter to unit suction line compatible fitting.

Sweat connect refrigerant suction line to 1 1/8-in. end of

adapter. Connect liquid refrigerant line to unit. When a

7/8-in. field-supplied suction line is used on 38SE003 or

38GR045, a field-supplied 3/4-in. to 7/8-in. suction line

adapter must be provided.

MECHANICAL CONNECTION (Mate one set of connec

tions at a time.)

1. Loosen nut on compatible fitting one turn. Do not

remove.

2. Remove plug and be sure 0-ring is in the groove inside

the compatible fitting.

3. Cut tubing to correct length.

4. Use gage on tag attached to service valve to mark tube

end for correct insertion depth. Insert tube into com

patible fitting until it bottoms. (Tube should be inserted

at least as far as mark on tubing.)

5. Tighten nut until it

bottoms

on back coupling flange

SWEAT CONNECTION (Use refrigerant grade tubing.)

1. Remove locking nut, rubber 0-ring and Schrader core

from valve.

2. Cut tubing to correct length.

Table 2 — Accessories

PART NO.

HH01AD040

HH93AZ040

HH51AR001

HH07AT070,

HH07AT074

HH93AZ076

HH01AD042

HH93AZ042

DESCRIPTION

Low-Voltage

Control

—

Honeywell

Deluxe

Thermostat

Thermostat Subbase

Comfort Control Center (Use with HH01AD040.)

Low-Voltage Control — Honeywell Thermostat

Thermostat Subbase (with Automatic Changeover)

Low-Voltage

Control

—

Honeywell

Thermostat

Thermostat Subbase

HH01YA092

HH93YZ094

32LT900301

Low-Voltage

Control

—

Grayson

Thermostat

Thermostat Subbase

Solid

State

Head

Pressure

Control,

and/or motor required.

Special field-installed fan

38GC900-152

38GB900021

UNIT

Motor No.

Fan No.

UNIT

Motor No.

38SE002,003

HC38VE851

LA01AA020

38GR002,003,004,045

HC38VE851

38SE004

HC40VL701

LA01AA023

38GR005,006

HC40VL701

Indoor Fan Relay (Six — 38BA400693)

Thermal Expansion Valve (Six — EA61DC100)

TUBING PACKAGES

Len gth

(ft)

L iquid

Suction*

UNIT

OD

(in.)

Tube End

OD

(in.)

OD

(in.)

Tube End

OD (in.)

Evap

Cond

38GC900031

10

%

Ve

Ve

Vet

Ve

38GC900041

18

Ve

Ve

Ve

Vet

Ve

38GS900221

25

Ve

Ve

Ve

Vet

Ve

38SE002, 38GR002

38GC900061

35

Vie

Ve

Ve

Vet

Ve

38GC900191

50

%

Ve

Ve

Vet

Ve

38GC900071

10

V

/8

Ve

%

Ve

Ve

38GC900081

18

V

/8

Ve

V

/4

Ve

V

/4

38SE003,004,045,055

38GC900091

38GC900101

25

35

Ve

Ve

%

/8

Ve

Ve

Ve

Ve

V

/4

Ve :

38GR003,004,045,005

38GC900in

50

Ve

V

'8

Ve

Ve

Ve

*Suction line is insulated and has a 90 bend at one end

fFor 5/8-in evaporator connection, cut off 3/4-in. end.

NOTE: Do not cut 3/8-in OD liquid line to a length shorter than 10 feet Do not cut 5/1 6-or 1/4-in liquid line.