Carrier 38SE User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

necessaiy, refer to Carrier Standard Service Techniques

Manual, Chapter 1, for system evacuation-dehydration

instructions.

When 38GR,SE condensing units are connected to other

than a Carrier evaporator, evacuate system and weigh in

charge shown in Table 5 or use sight glass method of

recharging.

D» iiot

toe sysieiss. A» om-

Weight Method

— Refer to Table 5 or unit nameplate for

correct system refrigerant charge. Blow any refrigerant

remaining in system before recharging.

When system is not evacuated, subtract the following

amount from total charge;

38GR,SE002 - .10 lb (1.6 oz)

38GR,SE003,004,045,005,055,006 - .20 lb (3.2 oz)

Keep refrigerant recharge within one oz of specified

charge on 002 systems and within 2 oz on 003,004,045,

005,055,006 systems.

Dial-a-charge charging cylinder is an accurate device used

to recharge systems by weight. These cylinders are available

at refrigeration supply firms.

Charging Chart Method

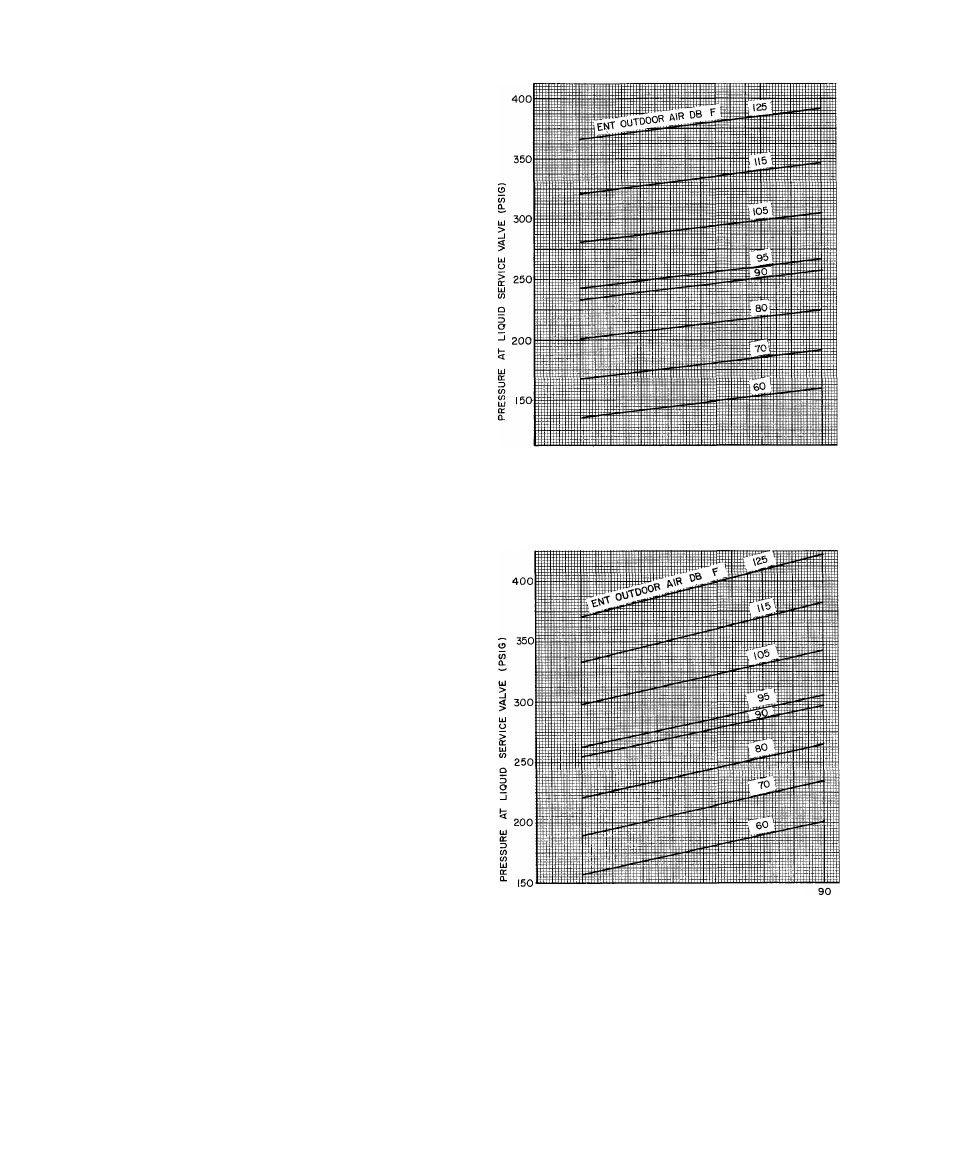

38GR THERMAL EXPANSION VALVE SYSTEMS - Use

Charging Chart, Fig 4 or Fig. 5. See Carrier Standard

Service Techniques Manual, Chapter 1, for procedure.

38SE CAPILLARY TUBE OR

ACCURATERT

m

SYSTEMS

— Use Charging Chart, Fig. 6, and the following procedure;

1. Operate unit a minimum of 10 minutes before checking

charge.

2. Measure suction pressure by attaching a gage to suction

valve service port.

3. Measure suction line temperature by attaching a service

thermometer to unit suction line near compressor.

(Insulate thermometer for accurate readings.)

4. Measure outdoor (condenser inlet) air dry-bulb temper

ature with second thermometer.

5. Refer to Charging Chart (Fig. 6). Find condenser air

temperature and project horizontally to curve showing

suction pressure.

6. From intersect point, project vertically downward to

chart suction line temperature.

7. If unit has a higher suction line temperature than chart,

add refrigerant until chart temperature is reached.

8. If unit has a lower suction line temperature than chart,

bleed refrigerant until chart temperature is reached.

9. If condenser inlet air temperature or unit suction

pressure changes, change to new suction line tem

perature on chart.

Chargemaster® Operation

— Operate unit 10 minutes

before using Chargemaster (Carrier Part No. 38GC680004).

1. Tape Chargemaster feeler bulb to suction line close to

condensing unit. Insulate bulb. Ensure suction line is

clean for good contact with bulb.

2. Connect refrigerant drum to Chargemaster inlet port

with drum in position for vapor charging.

3. Connect Chargemaster outlet port to unit suction valve

service port.

4. Crack valves on refrigerant drum and Chargemaster to

purge lines from drum to suction valve. After purging

lines, close valve on Chargemaster only.

5. Measure outdoor air dry-bulb temperature.

f

50

60

70

80

90

PRESSURE AT SUCTION SERVICE VALVE (PSIG)

Fig. 4 - 38GR002,003,004,045,005 Charging Chart -

TXV Systems

50

60

70

80

PRESSURE AT SUCTION SERVICE VALVE (PSIG)

Fig. 5 — 38GR006 Charging Chart — TXV Systems

6. Crack unit suction valve and read evaporator temper

ature at red needle position on Chargemaster temper

ature gage and suction line temperature at black needle

position.

CAOTICA;

'